Share this

Understanding the Dry Gas Seal API Standard for Optimal Gas Supply Efficiency in Northern California Refineries

by Malik Durojaiye on 10/28/21 9:00 AM

API 692 is a relatively new (2018) API standard for the minimum requirements of dry gas seal support systems. In petroleum and chemical industries, companies are using the API 692 standard to guide upgrades to current components and systems to not only meet the standards but ensure the long-term viability of components, meet the safety standards, and prevent leakage of gases into the atmosphere.

Due to being relatively new, API 692 standards are still not well known amongst some engineers. The purpose of this article is: (1) to inform the readers about these standards and, (2) to suggest what qualities and characteristics to look for in a seal support system.

Understanding API 692

API 692 sets the standard for dry gas seal operations. It aims to incorporate operational characteristics that are sources of system failure and requires the operator to take into account all potential reasons for system failure. It also requires that certain components meet performance and functionality requirements.

Operational Characteristics Set Forth by API 682

API 692 standards indicate that all potential reasons for system failure be accounted for in designing and implementing a dry gas seal. These reasons are varied to include the build-up of pressure, the lack of gas flow to sweep away debrief, the lack of gas flow for seal supporation, and the ability of the system to provide a continual flow of gas (if needed). The resulting change in temperature for a change in pressure is important as well as the gasses involved and their chemical interaction with the components.

Component Performance

API 692 also specifies required component performance and functionality. The largest change is the use of seal gas boosters. Seal gas boosters are now required (previously they were not) unless design specifications can ensure that they are not needed. Further seal gas boosters need to establish minimum pressure differentials between supply line gas and process gas. Other components of the system need to meet pressure, temperature, and flow thresholds, though these can be somewhat specific based on operational needs.

Ideal Characteristics of a Seal Support System

A seal support system needs to provide reliable seal performance to ensure that toxic and environmentally damaging pollutants do not enter the surrounding atmosphere. This is dependent upon a constant supply of gas at the correct pressure, temperature, and flow. By having the correct conditions and flow of gas, the dry gas seal can separate for operations and, by ensuring that seal faces are not making contact, allow dry gas seals to have a long operational life (approximately 10 years).

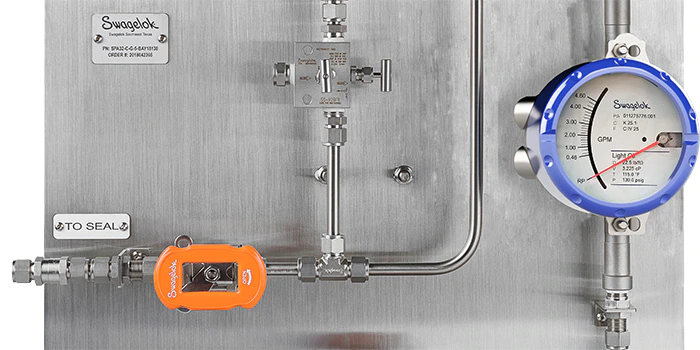

The seal support system consists of the components such as control valves, pipes, gas canisters, manifolds, and, if necessary, an auto change valve allowing a constant flow of gas. These components need to work in tandem to fit the specifications of operations. For example, the pressure specifications on all components need to correspond with overall system operational needs. The gasses and chemicals in the system need to be considered when deciding on the materials constructing components of the seal support system to limit corrosion. The rate of flow of gas as well as the operational needs for constant or variable gas movement also should be taken into account when deciding on components.

An expert in seal support systems can help make sure that the ideal seal support system components are used for the process and that these components meet API 692 standard specifications.

Rely on Expert Guidance to Meet the Dry Gas Seal API Standard

The API 692 standards have been designed to ensure suitable pressure and capacity. Standards and specifications are different, which is why you need a qualified engineer to interpret the standard for you, so as not to stray from it without a solid backing.

Having an expert that can make sure that system operations are meeting API 692 standards and that the seal support system is updated is essential. Dry gas seal performance is dependent on enough pressure and flow of separation gasses to move seal faces apart. Gasses also need the proper flow, pressure, and capacity to clear dust and contaminants from the system. Having a support system that does not meet API Standard 692 may result in problems with clearing contaminants from the system and ultimately damage to the seal. To ensure the long-term viability of dry gas seals, it is important to have an expert that can verify that systems are meeting API 692 standards.

A Swagelok Field Engineer can check systems for gas flow, capacity, and pressure. They can also work with operators to ensure the proper specifications and assembly are being followed to meet API 692 standards. Not only will this help ensure the long-term viability of dry gas seals and seal support components, but it will help ensure safety for the build-up of pressure and changes in temperature within the system.

Swagelok has been supporting the petrochemical industries in Northern California and Western Nevada for more than five decades. Our Field Engineers are available for on-site or virtual consultation. Based on our analysis, we’ll develop detailed renderings and technical documentation for your review and approval. An extensive inventory of the highest quality parts and components facilitates rapid fabrication and delivery of your dry gas seal support systems. Post-installation, Swagelok is available for support via phone, email, or on-site meetings to help ensure optimal performance.

To find out more about how Swagelok Northern California can help implement API 692 standards within your operations, contact our team today by calling 510-933-6200.

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)