Share this

VCO vs. VCR® Fittings: Make The Right Choice For Your Application

by Morgan Zealear on 8/8/23 9:00 AM

The semiconductor industry requires a great deal of precision in terms of purity and process control. Installing a vacuum system will facilitate control against contamination as well as pressure and temperature fluctuations at different crucial stages such as deposition, etching, and cleaning. The fittings used in such systems should be specifically designed to enable leak-tight seals to ensure maximum operational safety and production efficiency.

Fittings such as VCO O-Ring Face Seal fittings and VCR Metal Gasket Face Seal fittings provide maximum purity for a wide range of applications that require a vacuum-tight seal. Today, we will compare VCO vs. VCR fittings to help you identify the ideal fitting for your ultra-high purity application.

VCO vs. VCR Fittings: The Comparison

VCO and VCR fittings are both assets for applications that require extreme process control. In vacuum or high-temperature applications, these fittings provide a leak-tight seal to control particulates, which can significantly affect the yield. But to understand these fittings and when to use them, we need to take a look at their differences in terms of their build and their usage.

The table below compares VCO vs. VCR fittings.

VCO O-Ring Face Seal Fitting vs. VCR Metal Gasket Face Seal Fitting Fittings |

||

| VCO O-Ring Face Seal Fitting

|

VCR Metal Gasket Face Seal Fitting

|

|

| Feature |

O-ring face seal |

Metal to metal face seal |

| Clearance |

No axial clearance required |

Very minimal clearance required |

| Assembly opitions |

Gland + body + nut |

Female nut + glands (1 or 2) + gasket + body |

| Application |

For non-corrosive media—corrosion can be an issue on the O-ring |

Suitable when media is corrosive or for high-temperature applications |

| Temperature rating |

Maximum temperature rating is 550°F (perfluoroelastomer) |

Maximum temperature rating is 1000°F (316/316L stainless steel) |

Despite the difference, these VCO and VCR fittings are similar in terms of installation and accessibility. They can be easily installed without the need for specialized tools. For maintenance, repairs, and upgrades, they can be easily disassembled without requiring the removal of multiple other components.

Advantages of VCO and VCR Fittings

Making the right selection from VCO vs. VCR fittings is necessary to gain efficient output in your semiconductor manufacturing process. There are also several other benefits that these fittings offer, including:

- Leak-proof connections ensure no contaminant can enter the system to degrade the quality of the semiconductor device.

- Easy installation of these fittings reduces the time and effort required for system assembly.

- These fittings are made of highly durable materials and are available in a wide range of sizes, providing durability and flexibility in the design of custom vacuum systems.

- The ability of these fittings to resist high temperature, pressure, and corrosive media makes them suitable to use in multiple phases of semiconductor manufacturing.

- Their durability and reliability also make them cost-effective solutions.

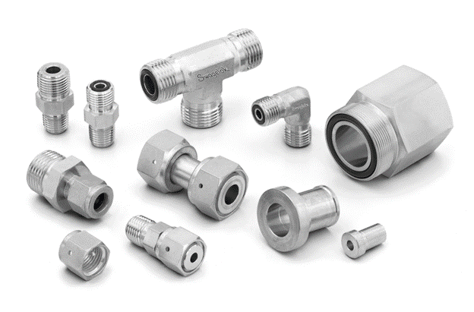

Use Swagelok’s Solution For Ease of Assembly, and Reliability

Swagelok’s VCO and VCR fittings are ideal for high-purity applications in semiconductors and a wide range of other industries. In high-vacuum or low-pressure environments, as may be required in semiconductor deposition, etching, or cleaning processes, these fittings can provide a leak-tight seal when joining different vacuum system components.

It is crucial to make the selection of VCO vs. VCR fittings based on application-specific requirements such as temperature and pressure capabilities, size range, and material compatibility, as well as sealing, assembly, and media requirements. The correct fitting choice is the key to your semiconductor manufacturing process's smooth and efficient operation.

To find out more about how Swagelok Northern California can help you make a selection between single ferrule vs. double ferrule tube fittings for your fluid system installation, contact our team today by calling 510-933-6200.

About Morgan Zealear | Product Engineer, Assembly Services

About Morgan Zealear | Product Engineer, Assembly Services

Morgan holds a Bachelor of Science in Mechanical Engineering from University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration and Mechanical Efficiency Program Specification (API 682), and he is well versed in B31.3 Process Piping Code. Before joining Swagelok Northern, he was a manufacturing engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)