Share this

The Importance of Orbital Welding Training of Stainless Steel Tubing

by Morgan Zealear on 6/14/22 9:00 AM

Welding stainless steel tubing requires understanding its type and microstructure, and physical, chemical, and thermal properties. For instance, austenitic steels can expand more quickly than ferritic steel during welding and therefore requires necessary arrangements to avoid thermal stress and weld zone cracking. Needless to say, the job demands experienced operators and careful observation throughout the process.

Thanks to orbital welding, industrial facilities in Northern California can now ensure weld repeatability, consistency, and efficiency without worrying about the type of stainless steel tube on the table. However, it still requires a well-trained workforce for a nuisance-free operation.

In this article, we discuss the advantages of automation over manual welding and the importance of orbital welding training for stainless steel tubing, specifically.

The Advantages of Automatic Orbital Welding vs. Manual TIG Welding

Operators prefer automatic orbital welding over manual TIG welding when it comes to enhanced precision and reliability. Some of the unique advantages of orbital welding are:

Open Platform Design

Automated orbital welding takes care of tedious manual control settings required to achieve desired travel speed, arc gap, and gas flow via electronic or mechanical means. That’s why the power supply utilizes an open platform that interfaces with standard devices and has scope for scalability in the future.

Hassle-free Programming

Unlike in manual TIG welding, creating programs for specific stainless steel tubes is less cumbersome in automated orbital welding machines. Custom settings can be saved and stored to create programs within a few minutes. That especially helps a new operator to optimize startup time and avoids any chance of human error.

Consistency

Despite hiring skilled operators, industrial facilities can’t expect the same consistency with hand welding that orbital offers. In contrast, when an electrode is programmed to automatically follow a fixed orbit around the weld and change positions with precision, there is hardly any room for human error.

Impeccable Data Management

Maintaining a daily written weld log for quality control in manual welding can be time-consuming. Automatic orbital welding machines can save time by collecting essential log details from operators before getting started, and then storing and synchronizing the operator details with existing data. This enables easy retrieval and transfer of log data during the time of need.

Orbital welding offers several advantages to help operators simplify their welding tasks. However, orbital welding training of stainless steel tubing is needed to fully take advantage of this automation and avoid costly welding mistakes.

The Importance of Orbital Welding Training for Stainless Steel Tubing

To ensure the reliability and consistency of orbital welding of stainless steel tubing, industrial facilities must invest in the proper training.

Understanding Gas Purging

The ability to control inside diameter (ID) purge gas is essential to retain weld quality and avoid corrosion or weld bead sagging. A thorough training program should teach proper gas purging techniques including selecting an ideal gas, setting the correct pressure and flow, and calculating the purge time.

Importance of Shielding Gas

Having a basic understanding of shielding gas is essential for orbital welding of stainless steel. In training, operators should learn how to use common gasses like argon and helium to protect electrodes and molten metal from atmospheric contamination without affecting metallurgical properties of stainless steel tubes.

Troubleshooting Expertise

Orbital welding isn’t impervious to occasional process anomalies. For instance, there could be improper welding or weld bead shifts due to sulfur content mismatch. While welding exotic metals like inconel or monel, not knowing how to preheat and cool the metal properly can lead to weld cracking. Orbital welding training teaches operators how to identify the root causes and mitigate them before they lead to costly issues.

Managing Sulfur Content

Sometimes, stainless steel tubes can deliberately have sulfur content to improve machinability. While trying to weld two stainless steel tubes with different concentrations of sulfur content, the weld bead may miss the joint and move towards a lower concentration. Only an expert can guide operators to overcome such challenges with ease.

It is imperative that industrial facilities upgrade their workforce with proper orbital welding training for stainless steel tubing to leverage the benefits of automation minus process mistakes often caused by manual welding. Plus, industrial facilities stand to benefit more by investing in orbital welding training by local equipment manufacturers.

Invest in Swagelok’s Orbital Welding Training for Stainless Steel Tubing

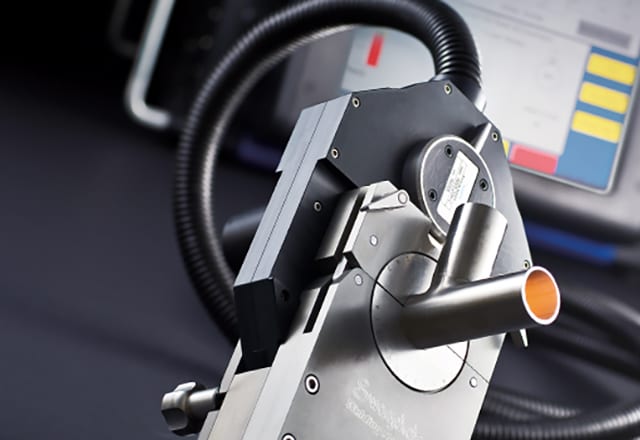

Swagelok, one of the leading solution providers in the fluid management industry, offers a five-day intense orbital welding training program for aspiring operators in Northern California. Trainees learn the essentials with Swagelok M200 Orbital Welding System.

The course qualifies for ASME Section IX and covers essential fundamental elements of orbital welding so that the trainees will learn about:

- Programming the power supply for different metals

- Determining and customizing the acceptable weld criteria (AWC)

- Properly setting the electrodes

- Using Purge and Pressurization to Prevent Weld Failures

- Predicting weld shrinkage

- Welding dissimilar metals and metals with dissimilar wall thickness

- Welding different alloys of the same metal

Also, the course maintains a perfect balance of classroom teaching and practical sessions to help trainees soak in essential working concepts with ease.

So, industrial facilities in Northern California that invest in Swagelok’s orbital welding training for stainless steel tubing (and more) receive training using a quality welding system—from the team behind the design. They have more acquired knowledge around dos and don'ts and can reap the many benefits of having a local training partner, such as post-training assistance to help trainees overcome challenges during live field operations.

To find out more about how Swagelok Northern California can help you with orbital welding training for stainless steel tubing, contact our team today by calling 510-933-6200.

About Morgan Zealear | Product Engineer, Assembly Services

Morgan holds a Bachelor of Science in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682), and he is well versed in B31.3 Process Piping Code. Before joining Swagelok Northern, he was a manufacturing engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)