Share this

Understand Seal Support Quench Systems to Avoid Costly Problems

by Malik Durojaiye on 4/20/21 8:45 AM

Many pumping processes in refineries circulate high-temperature, heavy hydrocarbons. The mechanical seals in many of these pumps often require a seal support quench system to prevent coking—which occurs when hydrocarbon particulates come into contact with air. Seal support quench systems are also leveraged to cool the seal or dilute any hydrocarbon leakage that makes its way across the seal faces to the atmosphere. In some medium-temperature hydrocarbon pumping processes, a quench is needed to heat the seal faces. For pumping processes operating below 0°C, a nitrogen quench is applied to prevent the atmospheric side of a mechanical seal from icing. A seal support quench system can be a low-cost alternative to dual/tandem mechanical seal configurations.

Quench fluid can be steam, water, or even nitrogen, depending on the process conditions. The quench is delivered to the atmospheric side of the mechanical seal. Steam is typically used in processes where solid hydrocarbon particles or water-soluble particles can form. Particulates that are removed via the quench are then drained into a collection system.

To get a better understanding of how a quench is delivered, let’s quickly look at two seal support quench systems: API Plan 51 and API Plan 62.

|

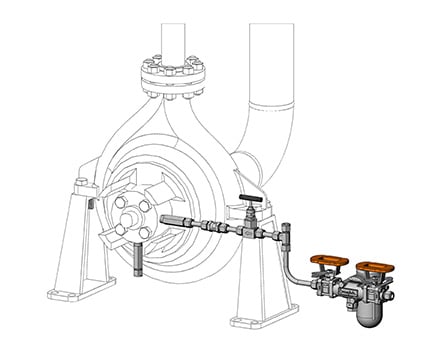

API Plan 51

|

|

|

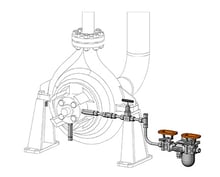

API Plan 62

|

|

Either of these two plans can also have a leakage collection system added. API Plan 65A is connected to the drain port on the gland and a reservoir collects normal leakage of condensing process fluid. The reservoir is kept constantly open to drain the collected fluid. The system monitors leakage and in the event of a seal failure, an orifice fitting on the system outlet lets a level transmitter trigger an alarm.

API Plan 65B connects to the gland drain port and collects normal leakage of condensing process fluid into a reservoir. In the event of excessive leakage, a level transmitter on the reservoir triggers an alarm. An outlet valve on the reservoir is typically left closed and opened only when there is a need to drain the reservoir.

Seal Support Quench System Design Decisions

Although these four API plans appear relatively simple in comparison to many other API plans, to obtain the best long-term performance from any seal support quench system, it’s best to work with experienced fluid system engineers. They bring the expertise needed to evaluate the pumping process, including process conditions, pump rating, type of mechanical seal, and available plant services. With that information, they can then begin to design the optimum quench system for the process. Critical seal support quench system design decisions may include:

- Avoiding contamination of bearings immediate to the gland plate by the steam or water quench by recommending a close bearing bushing and drainage system or a bearing bracket oil condition monitoring bottle

- Calculating the required reservoir volume and flow rate for API Plan 51 to ensure reliability and minimize the frequency of quench fluid replenishment

- Specifying the appropriate steam pressure (typically 3 to 5 psi) to remove solid accumulation from the atmospheric side of the seal

- Determining the correct steam temperature to avoid increasing the process temperature which would result in vapor pressure increases within the stuffing box

With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. You can also increase mechanical seal life and reduce MTBF for the pump by making the up-front investment in working with an experienced fluid systems engineer.

Swagelok: Global Expertise Applied to Local Process Needs

Whether you are planning a new pump installation or need to upgrade an existing pump because of changing process conditions, Swagelok brings more than five decades of fluid systems experience, including top-quality component manufacturing, best practices in system design, and ongoing technical support. We will work side-by-side with you to make sure your seal support quench system is properly designed, carefully assembled, and thoroughly tested prior to delivery. Our local field engineers are backed by a team of experienced professionals who have solved some of the most challenging seal support problems around the world.

To find out more about how Swagelok Northern California can help you obtain the best performance from seal support quench systems by providing expert on-site consultation and assembly services, contact our team today by calling 510-933-6200.

-1.jpg?width=192&name=image8%20(1)-1.jpg) About Malik Durojaiye | Field Engineer, Assembly Services

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)