Share this

A Fitting Tribute To Our Signature Product

by Jeff Hopkins on 1/29/20 8:45 AM

It has been over 70 years since the Swagelok tube fitting made its debut

"Swagelok Company was founded in 1947 by Fred A. Lennon

(1905-1998), with a $500 loan and the promise of a colleague’s design for an easy-to-install, leak-tight tube fitting.”

- From Swagelok History

Swagelok has such a deep catalog of fluid system components that sometimes we need a reminder of the company's starting point: the two-ferrule tube fitting.

It was 70 years ago that the Swagelok tube fitting made its debut. It was a revolutionary design that has been continuously refined over the decades. Let's look at four specific advantages:

Design

The Swagelok tube fitting outperforms other fittings in three key areas:

- Tube grip

- Gas seal

- Vibration resistance

Our unique SAT12 carburization process produces better performance. Swagelok fittings are easy to install and are backed by extensive training and an industry leading limited lifetime warranty. We conduct continuous, rigorous testing for extreme environments.

Materials

For optimal performance, Swagelok tube fittings are offered in a wide range of alloys to combat corrosion. They are made from only high-quality raw materials, and can be used in engineered combinations.

Manufacturing

We forge, machine, electropolish, weld, assemble, and test, all tube fitting in our own factory. We use optimized top-of-the-line tools and machining methods across 20 production facilities. Our robust Reliability Excellence program keeps equipment running at optimal efficiency. Traceability at all phases is an integral part of our overall quality system. Our Limited Lifetime Warranty is a promise as strong as our products.

Installation

Swagelok fittings come fully assembled, and connections can be reassembled many times.

Swagelok fittings come fully assembled, and connections can be reassembled many times.

They are easy to install, and our expert training equips your workforce with the essential know how.

Only standard wrenches are needed. Installers don't have to thread, flare, solder, braze or weld. And the Swagelok tube fitting requires significantly lower torque than most other tube fitting brands.

Performance

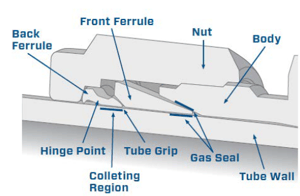

Swagelok tube fittings have a grip-type design that uses a unique "hinging and colleting" action, which provides more direct tube contact and gripping support. The gas seal - the burnishing/polishing action of the front ferrule creates concentrated zones of contact on the tube and on the body bevel for a stronger seal. The colleting region better isolates stress risers at the tube grip to resist bending, deflection, and vibration.

Swagelok tube fittings have a grip-type design that uses a unique "hinging and colleting" action, which provides more direct tube contact and gripping support. The gas seal - the burnishing/polishing action of the front ferrule creates concentrated zones of contact on the tube and on the body bevel for a stronger seal. The colleting region better isolates stress risers at the tube grip to resist bending, deflection, and vibration.

Supply Chain

Swagelok can support your success wherever it takes you. You have inventory available right here in the Bay Area and around the world, plus training classes and advisory services.

Refinery advantage

-1.jpeg?width=453&name=009%20(oil%20and%20gas%20,%20Petrochemical%20industrial%20plant%20power%20station%20-%20AdobeStock_140777468.jpg)-1.jpeg) If you are an instrumentation and control professional in an oil refinery, you understand the value

If you are an instrumentation and control professional in an oil refinery, you understand the value

of high-quality, reliable connections

to avoid critical and costly issues from leakage, improper Installation, corrosion and vibration.

The Swagelok tube fitting allows you to make repeatable, reliable leak-tight connections on process instrumentation systems. The patented case-hardening process and back-ferrule geometry produce an excellent colleting grip of the tube, minimizing the effects of vibration. Because this design uses consistent geometry instead of torque for gaugeable make-up, the Swagelok tube fitting can be used on a range of thick- or thin-walled, hard or soft tubing, while resisting the effects of pressure and thermal cycling.

Moreover, Swagelok tube fittings minimize fugitive emissions, as well as reduce process fluid leakage and operation costs.Simple installation, combined with consistent gaugeability upon initial installation, minimizes installation error.

It is painfully easy to improperly apply tape, and in almost every case you'll figure it out only after you trashed your fitting. Most galled fitting disasters we've seen were due to improperly applied thread tape. If you are on a tight schedule with little margin for error, mimimize the use of PTFE tape by using Swagelok tube fittings.

It is painfully easy to improperly apply tape, and in almost every case you'll figure it out only after you trashed your fitting. Most galled fitting disasters we've seen were due to improperly applied thread tape. If you are on a tight schedule with little margin for error, mimimize the use of PTFE tape by using Swagelok tube fittings.

Swagelok tube fittings are available in a variety of materials, including controlled 316 stainless steel and SAF 2507 super duplex for enhanced corrosion resistance in a variety of applications, including sour gas systems. In addition, the unique back-ferrule design and fitting geometry help eliminate dead spots and entrapment of corrosive fluids better than other connection methods.

The patented case-hardening process and back-ferrule geometry provide excellent vibration fatigue resistance—even in harsh or stressful environments, such as gas turbines, compressors, and pumps.

Just ask

From the humble tube fitting Swagelok built a global organization that can take care of all your fluid system needs. And your point of contact is right here in Northern California. Call us at 510-933-6200 or contact us through our website.

More like this:

- Swagelok Fittings (product page)

- The Swagelok Tube Fitting Advantage (info and download page)

- Help Me Choose (product selection service page)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)