Share this

How API Plan 72 Supports Mechanical Seal Reliability—And Why California Refineries Need Implementation Support

by Malik Durojaiye on 9/22/21 9:00 AM

In Northern California, refinery processes involving light hydrocarbons and high vapor pressure fluids often present challenges when it comes to ensuring that these gases and fluids remain safely contained within the systems, piping, and pumps involved in the process. To combat leakage and protect the atmosphere, dual mechanical seals and seal support systems that deliver buffer or barrier fluid to the seal are chosen to maintain seal reliability.

API Plan 72 supports mechanical seal reliability by supplying a clean, dry buffer gas (typically nitrogen) between the dual seals at a pressure lower than the process pressure. This allows minor amounts of process fluid to leak across the inboard seal into the buffer gas. The nitrogen dilutes process leakage from the inboard seal and sweeps it to a vapor recovery collection system. For condensing leakage, API Plan 75 is used as the collection system; for non-condensing leakage, API Plan 76 would be used for the collection of primary seal leakage.

When installed properly, API Plan 72 can support mechanical seal reliability that leads to successful and safe operations and reduced operating delays; but, this isn’t always the case. Improper implementation of API Plan 72 can lead to issues with pressure and interplay issues with other system components (e.g., Plan 75 and Plan 76 leak detection systems. By consulting with a reputable seal support system vendor, consequential problems—as discussed in this article—can be avoided.

What Can Happen With Improper API Plan 72 Implementation

There are several issues that can occur when API Plan 72 isn’t installed properly to support the mechanical seal. These issues can lead to leaks, damage to system components, and even explosions with a build-up of pressure.

Pressure Calibration Issues

In a properly installed API 72 Plan, a pressure regulator sets the gas pressure no higher than the required psi as it enters the seal chamber. The pressure in the system should be limited based on the gas substance used in the system (typically, nitrogen). This should not be more than 10 psi (0.68 bar). Similarly, the pressure regulator and the alarm point on the leakage collection system on the panel should be adjusted based on the gas substance used. Buffer gas pressure should also be less than the seal chamber pressure.

If there’s an issue with Plan 72 implementation, proper pressure calibration is at risk, leading to damage to the seal which ultimately results in leakage. Further, damage to the seal can result in water vapor entering the system which will result in ineffective refinery processing. Finally, the ineffective control of pressure can also result in ineffective control of temperature. This is particularly problematic as Plan 72 provides necessary icing on cold applications and some cooling to the outer seal.

System Integration Problems

API Plan 72 should also be able to seamlessly integrate with other seal support system designs such as Plan 75 and Plan 76 because these leakage detection systems aid in supplying low-pressure buffer gas. It is important to release the proper amount of gas between the inner and outer containment seal. Poor integration of an API Plan 72 design may result in the inability to prevent fugitive emission from escaping to the atmosphere due to primary seal leakage not being swept away.

By working with experts, issues with pressure and temperature and the resultant leaks and ineffective processing can be avoided.

The Benefits Expert Guidance for API Plan 72 Installation

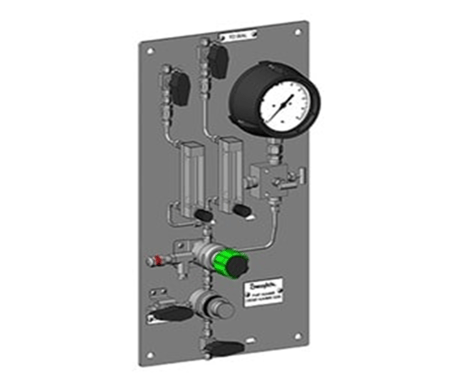

Properly installed API Plan 72 panels and kits provide a clean, regulated gas supply to a dual unpressurized seal arrangement. The benefits of Plan 72 include preventing leaks to the atmosphere and maintaining proper pressure and temperature in the system.

Seamless Integration

Seamless integration among systems helps to prevent leakage and allows for proper temperature and pressure control. For instance, it is important to determine if API Plan 75 or Plan 76 (both commonly used with API plan 72) are needed in conjugation with Plan 72. Whereas Plan 75 should be used as the collection system for condensing leakage, Plan 76 should be used for the collection of primary seal leakage for non-condensing leakage.

Leak Prevention, System Reliability, and Safety

When implemented properly, API Plan 72 provides a fail-safe for other seal failures and prevents the build-up of pressure. Plan 72 serves as a containment seal in the event of inboard seal failure. It utilizes a buffer gas that is passed through a containment seal chamber to sweep leakage away from an outer seal collection system. Nitrogen gas cools seal faces and high vapor pressure liquids. As such, API Plan 72 can support mechanical seal reliability and may prevent larger and more costly issues which may occur due to damage from high-pressure gasses.

Swagelok Expertise Aids Mechanical Seal Reliability With Proper API Plan 72 Implementation

If any of your currently installed mechanical seal support systems, such as API Plan 72, are underperforming in their ability to capture and recover hydrocarbons because of changes to process conditions, aging components, maintenance difficulties, or poor design and implementation, Swagelok will work with you to understand the issues and recommend solutions that eliminate those problems. Our local Field Engineers will conduct an onsite analysis of the pumping process, identify factors that undermine performance, and recommend components, design changes, upgrades, or even replace seal support systems, if necessary.

For more than 50 years, Swagelok has been serving the needs of the chemical and petroleum industries in Northern California. Swagelok maintains an extensive inventory of top-quality fluid system components in our Bay Area facilities. Our local technicians can quickly build and test any assemblies or complete seal support systems prior to delivery. When you work with Swagelok, you benefit from our refinery experience, the convenience of local support, and the backing of worldwide Swagelok industry expertise.

To find out more about how Swagelok Northern California can help you with mechanical seal reliability and API Plan 72 implementation for your seal support system needs,contact our team today by calling 510-933-6200.

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)