Share this

Top 4 Benefits of Dry Running Containment Seals—And Their Support Systems

by Malik Durojaiye on 9/14/21 9:00 AM

Dry running containment seals appear very similar to traditional wet seals at first glance. They have non-contacting mechanical faces—a rotating ring and a stationary ring. Dry gas seals are typically used in centrifugal compressors or pumps in petrochemical processing and gas transmission.

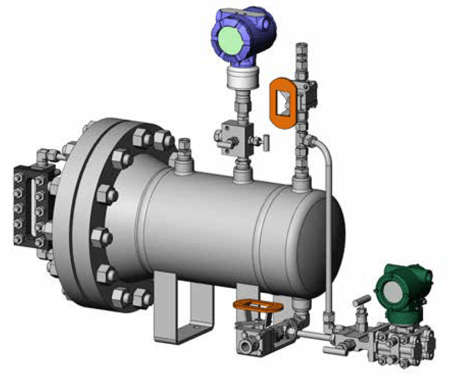

Dry gas seals need a supply of dry gas to maintain the required seal chamber environment. For compressors, the source is the compressor discharge which is filtered and delivered to the seal chamber. For centrifugal pumps, it’s usually plant nitrogen delivered at the appropriate pressure and flow by the seal support system.

Dry running containment seals are less common than wet seals, but they play a critical role in many petrochemical processes and offer some significant benefits. Below, we’ll look at four of the biggest advantages of dry running containment seals.

1. Improved Reliability and Seal Life

Reliability is the main advantage of dry running containment seals over wet mechanical seals. They operate under low-pressure, dry running conditions for the majority of their life. Because they are non-contacting, wear is negligible and their theoretical lifetime is limited only by secondary sealing elements. It’s not unusual for dry running containment seals to operate for ten years or more before being refurbished—much longer than wet seals.

2. Reduced Emissions/Leakage

Because the seal face clearance is so small with dry running containment seals, leakage to the atmosphere is very low. Gas seals reduce leakage tenfold over wet seals because of the very thin clearance between the seal faces. This can result in cost savings for the end-user and reduced tax penalties on gas flaring.

There may be special HSE compliance requirements for volatile fluids that pose environmental risks if leaked to the atmosphere. API Plan 74 offers a reliable means of preventing these emissions. API Plan 74 delivers pressurized barrier gas, usually plant nitrogen, to a dual seal arrangement, providing a high level of reliability against leakage of hazardous fluids. Because of these capabilities, API Plan 74 is appropriate for dry gas seals in pumps or compressors used for:

- Process fluids containing solid particulates

- Toxic or hazardous fluids

- High-vapor pressure fluids

- Volatile light hydrocarbons

- Clean, non-polymerizing fluids (polymers are problematic for inboard seal faces)

3. Reduced Installation and Operating Costs

A dry running containment seal is similar to a traditional mechanical seal, except it is designed with high precision to negate the need for liquid lubrication at the sealing faces, which can also be source of contamination. If the process fluid is clean and dry, the dry seal doesn’t require a flush, and no reservoir is required—just the plant nitrogen line. Because the seal doesn’t require as many components to support it as a wet seal, the installation is typically simpler and less costly.

Dry running containment seals have lower operating costs, too. They use significantly less energy since they don’t require subsystems like seal oil pumps and degassing tank heating systems. The simplicity of dry running containment seals also means routine maintenance is less frequent and less costly than with wet seals.

4. Safe Sealing of Hazardous Fluids

Dry running containment seals are especially useful for preventing leakage of hazardous, flammable, or toxic vapors from the process fluid. The faces of a dry running containment seal are designed for sealing high gas pressures and are very tolerant of pressure fluctuations in the hydrocarbon recovery or flare system.

Under normal conditions, the containment cavity is under low pressure, and no liquid contacts the outboard seal faces. Normal leakage from the primary seal is vented or drained away by the buffer or barrier gas. If the primary seal fails, the containment seal can prevent the process fluid from leaking to the atmosphere by temporarily operating at the process fluid conditions with the process fluid lubricating the seal faces.

API Plan 76 is used when primary seal leakage consists of non-condensing vapors. This plan works in combination with a buffer or barrier gas to safely vent leakage to a flare or vapor recovery system. It can be outfitted with an alarm to warn when pressure indicates the primary seal is about to fail.

Seek Expert Help for Designing and Installing Dry Running Containment Seals

While dry running containment seals may seem relatively simple, if you’re replacing older wet seals with dry running containment seals, or you’re installing a new dry running seal support system, it’s a good idea to seek the guidance of an experienced seal support system expert from a reliable vendor like Swagelok.

An experienced dry running containment seal vendor will help you determine the proper seal arrangement for your process conditions. Our Field Engineers can perform an onsite evaluation of your process and design, fabricate, and thoroughly test the API plan that best meets the process requirements.

Swagelok has been supporting the petrochemical industry in Northern California for more than five decades. Our Field Engineers have the experience and expertise to make sure your dry running containment seals are designed and installed safely and operate reliably. We’re always available for support via phone, email, or on-site meetings to troubleshoot dry gas seal problems and improve performance.

To find out more about how Swagelok Northern California can help you select the right API plan for dry gas seals for your specific process needs, contact our team today by calling 510-933-6200.

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)