Share this

Falling Asleep at the Analyzer?

by Jeff Hopkins on 8/30/18 1:00 PM

An online analyzer means the difference between knowing a process chemistry result within minutes versus hours or even days later

"Connecting a process analyzer to an industrial plant may seem to be a simple task; but really, it’s quite complex. It demands a melding of instrumentation, analytical chemistry, and chemical engineering knowhow, and few people are skilled in all of those technical arts."

- Tony Waters, from the Preface in Industrial Sampling Systems

Swagelok offers Grab Sample Modules for gas and liquid systems. Check out information on both and get the literature, including a selection matrix.

Delay in sampling systems

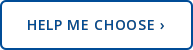

Today's chemists and process engineers have access to incredibly advanced online analytical equipment. An online analyzer means the difference between knowing a process chemistry result within minutes versus hours or even days later. One of the most important aspects of a sample is that it is an accurate representation of the material being sampled. You might be thinking, "DUH", and you'd be right; however, this mistake is disturbingly common. When running an online analyzer, a sufficient amount of time must be given to purging the sample lines before taking the measurement. Purging involves flushing the sample lines with process chemistry until all of the internal volume is filled with the same chemistry as the process line.

So how do you know how long to purge?

To figure out purge time it's important to know 4 things:

- Volumetric flow rate at standard temperature and pressure

- Live volume

- Dead volume

- System pressure for gases

Volumetric Flow Rate determines how much in how long; the higher the flow rate, the shorter the purge time.

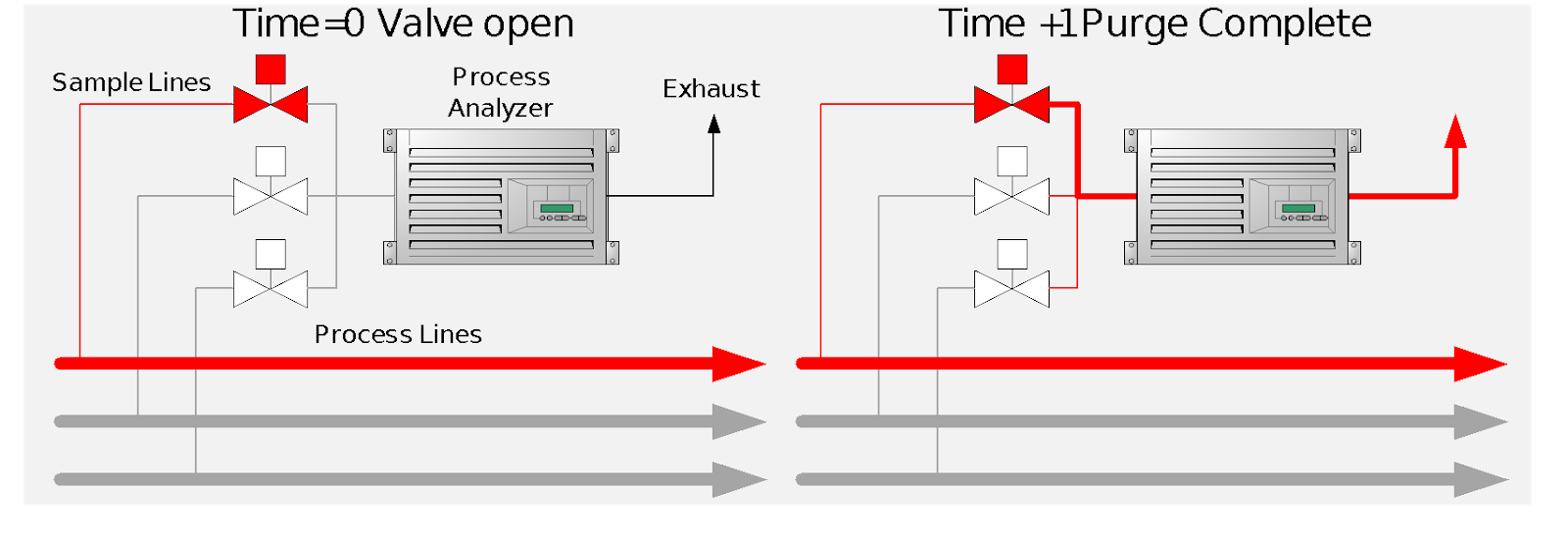

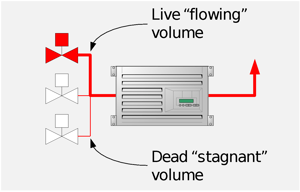

Live Volume is the physical volume in the direct path of flow from the sample tap point to the analyzer. For a representative sample, at least one complete purge of the entire live volume is necessary.

Calculate your live volume by multiplying the fluid cross sectional area of your sample line with the length of the line. For instance, if I have a tube with a 4mm internal diameter that is transporting a sample 8 meters, the internal volume of the line is approximately 100ml.

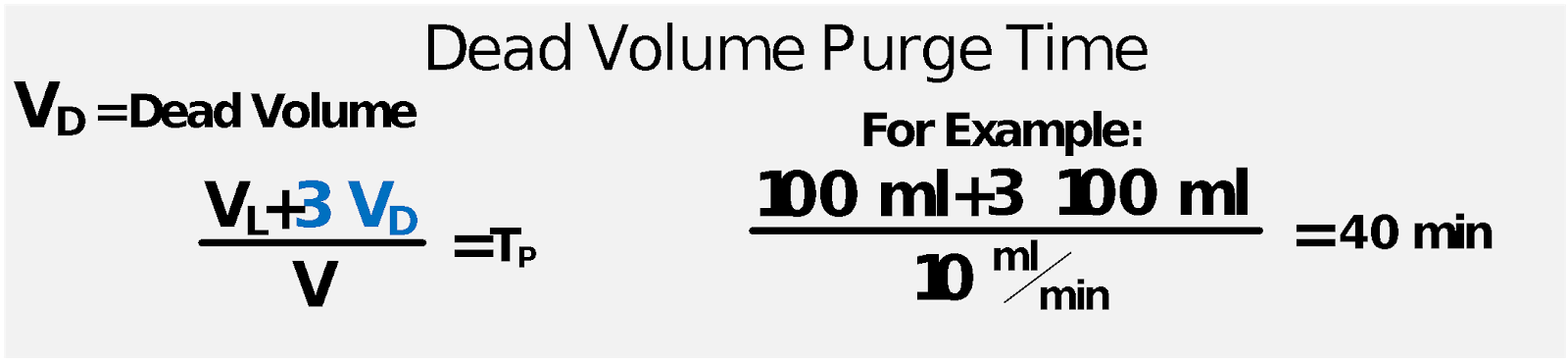

Calculate your live volume by multiplying the fluid cross sectional area of your sample line with the length of the line. For instance, if I have a tube with a 4mm internal diameter that is transporting a sample 8 meters, the internal volume of the line is approximately 100ml.With flow rate and volume, you can begin to calculate purge time:

Dead Volume is made up of the volumes that sit mostly stagnant in a sample line. Also referred to as mixing volumes (though not necessarily the same thing) dead and mixing volumes are typically located in things like gauges, filters, entrapment areas in valves, condensate pots, and stagnant non-flowing connections in the same line. In this case a representative sample requires at least three times the "mixing" volume to be purged out. This is where you may start to feel a bit of animosity towards that condensation pot knocking the liquid out of your wet sample gas.

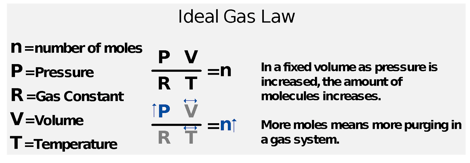

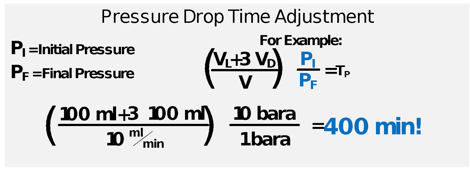

System Pressure for gas samples matters big time. Since gasses are compressible, the higher the pressure, the more delay is built into the sample. Think of it in terms of molar amount using the ideal gas law. Pretty much all analyzers decompress the sample gas to atmospheric pressure when taking a measurement. Because of this decompression, gas velocity on the inlet of the analyzer will be a proportional amount lower than the gas velocity on the outlet, so you can express the time delay by adding a pressure drop factor to your sample time calculation. A lot of engineers make the classic error of more pressure means more flow and more flow equals a faster sample right? After adding the 10x multiplier to the sample time, you may be left questioning your own sanity when your online analyzer doesn't seem to work at all. So before you start calling up the company you bought the analyzer from it's a good idea to take a good look at your sample lines first!

Resources are available!

The above is just the tip of the iceberg when it comes to considerations for a sampling system. Several years ago it became clear to us that our customers needed extra help when it came to sampling systems. We answered the call and partnered with industry leaders to bring you the Swagelok reference guide to Industrial Sampling Systems. What you have read so far is only about 4 pages or so from the more than 700+ that make up the Industrial Sampling Systems reference guide.

The above is just the tip of the iceberg when it comes to considerations for a sampling system. Several years ago it became clear to us that our customers needed extra help when it came to sampling systems. We answered the call and partnered with industry leaders to bring you the Swagelok reference guide to Industrial Sampling Systems. What you have read so far is only about 4 pages or so from the more than 700+ that make up the Industrial Sampling Systems reference guide.

This hardcore engineering text is jam packed with loads of applied knowledge for thermodynamics, fluid dynamics, fluid systems engineering, and more. If you find yourself falling asleep waiting for your sample perhaps you could prop your head up with this mighty tome and gain some knowledge through osmosis!

The same experts that helped us write this book also helped us develop Pre-Engineered Subsystems and Grab Sample Modules, so you can standardize your sampling system as well as an educational program.

(Prefer to talk live? Please give us a call at 510-933-6200.)

- Sampling System Best Practices Articles (section of this website)

- 10 Sampling System Mistakes Harming Your Operation (blog article)

- Tony Waters Wrote the Book on Industrial Sampling Systems (blog article)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)