Share this

FAQ: How Do Regulators Cut Delay?

by Jeff Hopkins on 7/26/18 8:04 AM

Gas travels faster when pressure is lower, so a regulator can speed up a sample in an analytical system

"One way to control time delay is with a regulator. Regulators control pressure, and pressure in an analytical system is closely related to time. In the case of gas systems with a controlled flow rate, the lower the pressure, the shorter the time delay."

- Doug Nordstrom, Swagelok Co and Dean Slejko, Swagelok Co

We've written about the many causes of time delay in sample systems, and how that can hurt the results that come out of an analyzer. The industry standard to aim for is one minute from the process line to the analyzer, but many potential delays lurk along the way.

Today we'll look at one component that can reduce time delay: the pressure regulator. In an analytical system, time is closely related to pressure. In gas systems with a controlled flow rate, the lower the pressure, the shorter the time delay. So it makes sense that a pressure regulator could be a useful tool.

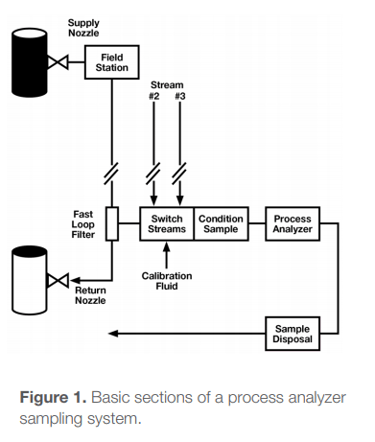

Delay may occur in any of the major parts of an analytical instrumentation system, including the process line, tap and probe, field station, transport line, sample conditioning system, stream switching system, and analyzer. For now, we will focus on the field station and the important role of a regulator in reducing time delay there

Before the field station

Minimizing time delay begins with the location of the tap. It's best to put the tap as close to the analyzer as possible, but it should be upstream of sources of delay, such as drums, tanks, dead legs, stagnant lines, or redundant or obsolete equipment. When sampling a liquid, pressure at the tap should be sufficient to deliver the sample through the transport lines or fast loop without a pump.

You may not always be able to dictate the location of the tap. You may have to make do with an existing tap location, and often an existing analyzer shed location as well. If the tap is far from the analyzer, a fast loop will help you quickly deliver fluid to the analyzer and return the unused portion to the process.

How To Use A Regulator To Reduce Time Delay In An Analytical System (Like this blog, get the tech paper)

At the field station

In cases where the analyzer requires a liquid sample, a regulator in the field station is not needed. It is better to keep liquids at high pressure to avoid the formation of bubbles. But for a gas sample, a field station is a means of reducing pressure in the transport lines. Time delay decreases in direct proportion to absolute pressure. At half the pressure, you will get half the time delay.

Let’s look at three possible applications for a regulator, each with a different configuration. In the first application, the objective is to reduce gas pressure. The pressure drop is not expected to produce condensation, so all you need is a simple pressure-reducing regulator.

In our second regulator application, the pressure drop is expected to cause condensation. With a drop in pressure, almost all gases lose heat, which is known as the Joule-Thomson effect. If the gas is close to its dew point, this cooling could cause condensation. In some cases, the loss of heat may be great enough to cause the regulator to freeze up. A heated regulator may be required to keep the temperature of the gas above the dew point.

In our third regulator application, a liquid must become a gas before it can be analyzed by a gas chromatograph or other analyzer. In this case, you'll want a vaporizing regulator. Vaporizing regulators are tricky but if properly sized and installed, they can be a reliable means of preparing a liquid sample for analysis in a gas analyzer.

Industrial Sampling Systems, the definitive reference guide by expert Tony Waters (book excerpt)

The objective of a vaporizing regulator is to instantly flash the entire sample into a gas, which requires a lot of heat applied at the precise location of the pressure drop. With vaporizing regulators, pay close attention to temperature and vapor flow rate. If the flow is too great, the sample will be only partially vaporized and liquids will flow through the regulator and toward the analyzer. If the vaporizer temperature is too high, the liquid sample upstream will vaporize.

In cases where a liquid is being vaporized, consider a liquid fast loop followed by a slow loop. The objective is to keep the liquid moving right up to the vaporizing regulator.

There's still more to learn about how to find the right settings for heated regulators and vaporizing regulators. We lay out the details in a three-page technical paper that you can download for free. And for the full range of information on the subject, see the Swagelok book Industrial Sampling Systems (2013), the definitive sampling systems reference guide by expert Tony Waters.

Swagelok Grab Sampling Systems Application Guide (Catalog)

More like this:

- View all FAQs posts at this blog (list of blog articles)

- View Swagelok technical articles on analytical instrumentation (page at this website)

- Tony Waters Wrote the Book on Industrial Sampling Systems (blog article)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)