Share this

Ideal Match: Orbital Welding and 316L Stainless Steel Tubing

by Jeff Hopkins on 11/20/18 9:00 AM

It avoids the crevices and crevice corrosion common with mechanical couplings

"Pitting corrosion is the most common failure mode in welded 316L. Pitting is a form of localized attack caused by a breakdown in the thin, passive oxide film that protects stainless steel from the corrosion process."

- From Electropolished Tubing: Avoiding Corrosion in Welded Applications (Technical Paper)

One of the most popular components in fluid system applications is American Iron and Steel Institute (AISI) 316L tubing. Look inside bioprocessing and pharmaceutical plants, and you'll likely find large systems of AISI 316L tubing orbitally welded in place.

Why orbitally welded? In previous posts we've written about the fact that orbital welding is faster and more consistent than doing the process by hand, especially after a full day of welding. There's one more advantage: corrosion resistance.

Two types of corrosion

Bioprocessing applications are usually wet, introducing the possibility of rouging and microbially induced corrosion. Rouge is a contaminant consisting of various forms of iron oxides found in many hot water and steam systems. Treating rouge usually means shutting down, cleaning and repassivating the entire system.

Microbially induced corrosion begins in the heat-affected zones of welds, as well as in crevices or cracks. It occurs when aerobic and anaerobic microbes create a colony by removing material, forming deep pits with small pinhole openings on the interior of the tube. It can speed up corrosion drastically. A system designed to last 10 years can fail in two years or less.

Electropolished Tubing: Avoiding Corrosion in Welded Applications (Technical Paper)

Materials matter

Orbital welding is one way to keep corrosion at bay. It avoids the crevices — and the potential for crevice corrosion — common with mechanical couplings. Properly done, orbital welding gives a smooth, straight, flat or slightly beaded surface.

But it takes the right formulation of steel to get the most out of orbital welding. That's right, not all 316L stainless steel is created equal. Minor changes in composition can alter the way in which 316L solidifies during welding. A higher level of d-ferrite, for instance, reduces the tendency for hot cracking, but it also stimulates pitting corrosion. Pitting is caused by a breakdown in the thin oxide film that protects stainless steel from corrosion.

Swagelok metallurgists wanted to find the optimum 316L compositions that would allow for strong welds that also stand up in corrosive service.

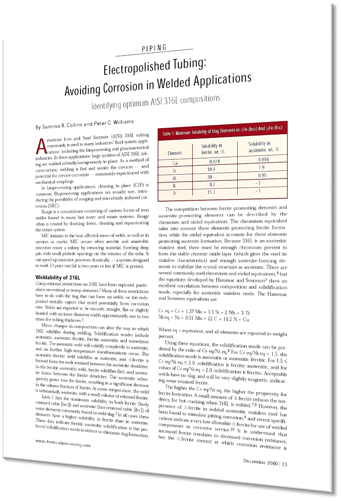

First they did a weldability study, taking samples from seven heats of commercially available 2-inch diameter 316L electropolished tubing. All the samples were orbitally welded using fixed parameters. When the welds had all cooled, they were inspected for slag and appearance, and the amount of ferrite was measured.

Next, our metallurgists conducted a corrosion study. This time they took 21 heats of 316L tubing, and again had them all orbitally welded in the same way. Afterward, they measured the ferrite in each weld, and put the welds through a corrosion test.

Swagelok Welding System - M200 Power Supply (catalogs)

Results

The experiments showed that corrosion resistance of welded 316L falls off dramatically when ferrite in the weld exceeds 3 percent. This kind of information is crucial when we set the formula for the 316L stainless used in Swagelok tubing. The metallurgists noticed an optimum ratio of chromium over nickel that minimizes both the contaminating and corrosion prone effects of welded connections. A ratio of less than 1.45 produces too little ferrite in the weld to dissolve the slag particulate generated by the welding operation. A ratio higher than 1.55 generates too much ferrite in the weld, which leads to noticeably less resistance to pitting corrosion.

We want our Swagelok parts, tools and services to work in harmony so that our customers get the best results from all three. Stainless steel tubing, joined with our Swagelok Welding system, which you can operate with confidence thanks to our training courses. That's a winning combination that will help your fluid system give you top service for a long time.

Swagelok Stainless Steel Tubing and Tube Support Systems (catalogs)

More like this:

- Good Orbital Welding Still Relies On Human Choices (blog article)

- Beyond Basics: Swagelok's Advanced Class In Orbital Welding (blog article)

- Swagelok technical articles on analytical instrumentation (section of this site)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)