Share this

Nice Threads! Make Sure You Keep Them That Way

by Jeff Hopkins on 6/19/19 8:45 AM

What to look for in pipe threads, and how to make sure you get a good seal

"Threads have peaks (called crests) and valleys (called roots). The part in between the crest and the root is called the flank."

- From There's Nothing Like a Set of Well-Fitting Threads

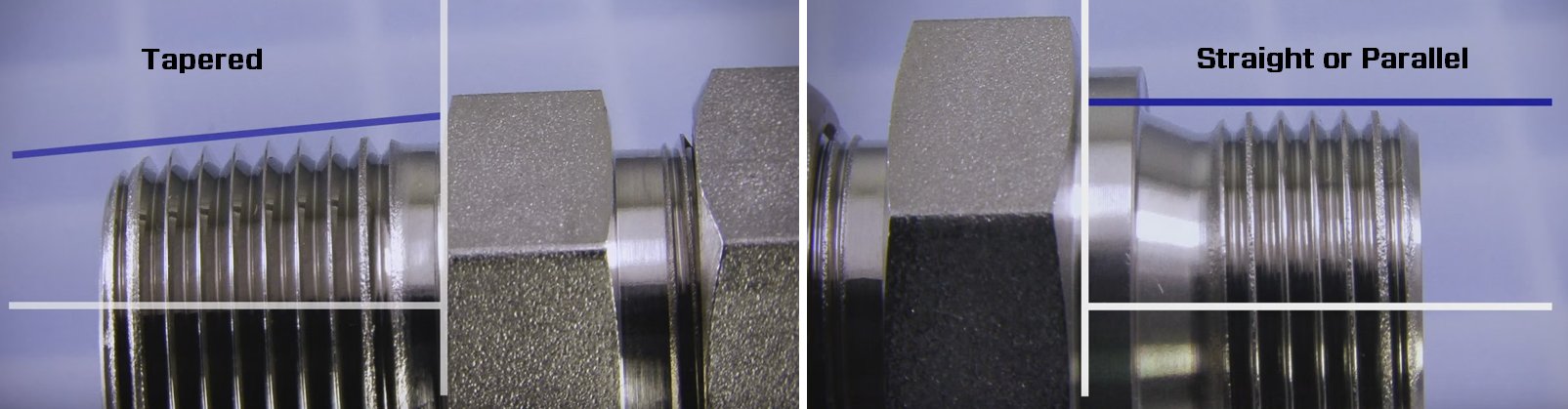

Even in the 21st century, the world of fluid joints is still dominated by tapered pipe threads, a standard that was introduced in 1864. Tapered fittings are made with a slight pitch in the threads. Thread sealing tape or pipe dope is applied to the male threads and the joint is screwed together. The taper makes the connection tighter and tighter with each rotation until a seal is achieved. The two primary standards are NPT or BSP.

Tapered pipe fittings still dominate fluid system devices such as solenoid valves, pressure regulators, and pressure vessels. There are two big reasons: Tapered threads are very well defined across multiple industries for code compliance, and tapered threads are fairly easy to make.

That being said, I don’t know a fluid systems engineer or assembler who doesn’t have a love/hate relationship with tapered pipe threads. Time and time again, the sealing tape or dope is improperly applied and the joint sees metal-to-metal contact, resulting in severe galling and a frozen un-sealed fitting. This can be an extraordinarily expensive setback when it happens on expensive components and the parts must be scrapped.

That being said, I don’t know a fluid systems engineer or assembler who doesn’t have a love/hate relationship with tapered pipe threads. Time and time again, the sealing tape or dope is improperly applied and the joint sees metal-to-metal contact, resulting in severe galling and a frozen un-sealed fitting. This can be an extraordinarily expensive setback when it happens on expensive components and the parts must be scrapped.

Often technicians will try to cool the male side down and heat up the female side with a torch to use thermal expansion to get the two pieces apart. It’s a lucky break when you can repair damaged threads with a tap-and-die set. I know technicians that have spent about six hours with a jeweler’s file slowly and painfully restoring galled threads on a custom part that couldn't be replaced.

Here are some techniques that you can follow to help prevent a disaster from killing your schedule and budget.

Look Before You Leap

Every male thread Swagelok produces is installed with a plastic protective cap for shipping. Protective covers keep threads from being accidentally dented or otherwise marred. A dent in a male pipe thread is a time bomb. Once installation begins, the damaged portion of the thread won’t necessarily be noticed until the joint begins to tighten. After the joint starts to get tighter it’s very normal for an installer to continue for another turn or two to make a good seal. The damaged portion of the threads makes an installer think the joint is sealing up, when in reality the damaged thread has been tearing up the female threads making the joint tighter without sealing. After the joint fails leak testing and the installer goes to disassemble the joint, it becomes clear what has happened. In most cases the article must be scrapped.

Always inspect the threads of the parts you are getting ready to assemble. It costs practically nothing. A few minutes replacing a faulty fitting before you destroy the threads on an expensive pressure regulator or manifold will save you thousands of dollars in the long term.

Tape and Dope

The two most common ways to seal a threaded fitting are Teflon tape applied to the threads or pipe dope.

PTFE tape is fairly convenient to use, comes on small portable rolls, and is easy to keep in your tool bag or box without adding much weight. PTFE tape doesn’t require any cleanup, apply it to the thread, assemble the joint and you are all set. Follow this link to view a video on how to apply pipe thread sealant.

Quick look-PTFE Tape:

- Temperatures up to 450°F (232°C)

- When applied properly, PTFE tape acts like a lubricant to reduce thread damage during assembly

- No cure time – system can be pressurized immediately after assembly

- Swagelok PTFE tape has a 0.035 to 0.004 thickness so it works well in both liquid and gas service

- No clean up needed

It is painfully easy to improperly apply tape, and in almost every case you'll figure it out only after you trashed your fitting. Most galled fitting disasters I’ve seen were due to improperly applied thread tape. If you are on a tight schedule with little margin for error, avoid the use of PTFE tape.

By far, pipe dope is my preferred solution for a threaded fitting. Swagelok makes a high-quality dope called SWAK. It can be a bit of a messy goop, but it's much more fool proof. It applies to the male threads like a thick grease and keeps threads lubricated throughout assembly. I’m not saying it’s not possible, but I have never shredded a fitting when using SWAK.

Quick look - SWAK:

- Temperature rating: -65 to 350°F (-53 to 176°C)

- Anaerobic sealant cures to a bond that resists vibration or shock

- Clings to threads and will not shred or tear on assembly, reducing the possibility of PTFE tape entering your system

- Allows low breakaway torque for easy-to-break connections, even after fully cured (24 hours)

The main disadvantage of liquid thread sealant is that it requires 24 hours to cure before you can put it into service. Liquid sealant is also a little more of a mess to clean up, so make sure you have plenty of rags to wipe off the fittings. Follow this link to learn more about Swagelok pipe thread sealants.

Thread Lubricants

If you've looked through our catalog of thread sealants, leak detectors, and lubricants you likely have also seen Goop products. Silver, Pure, Blue, and Vac Goop are all thread lubricants.

Lubricants aid fitting assembly and disassembly, especially when threads are rough or temperatures may swing to extremes. It’s not uncommon to use a thread lubricant over PTFE tape as an aid for fitting assembly. Thread lubricants can be used on all kinds of threaded fasteners and parallel thread fittings. It’s important to note that thread lubricants are not thread sealants and we do not recommend replacing SWAK with any Goop product.

Just ask

Swagelok Northern California has a great deal of exposure to all aspects of fluid system design and engineering. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

- Swagelok Thread and End Connection Identification Guide (download page)

- There's Nothing Like a Set of Well-Fitting Threads (blog)

- Leak Detectors, Lubricants & Sealants (product page)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)