Share this

Single Ferrule vs. Double Ferrule Tube Fittings

by Morgan Zealear on 6/6/23 9:00 AM

In oil and gas refineries, tube fittings are crucial in connecting sections of tubing and components such as valves or pumps to form a reliable fluid transport system. Depending on the application and their operating conditions, there are various tube fittings to choose from—instrumentation fittings, compression fittings, and flare fittings, to name a few. Despite the difference in application, these tube fittings share some common goals, which are:

- Holding the tubing in place

- Providing a leak-tight seal

- Ensuring corrosion resistance

Single Ferrule vs. Double Ferrule: The Comparison

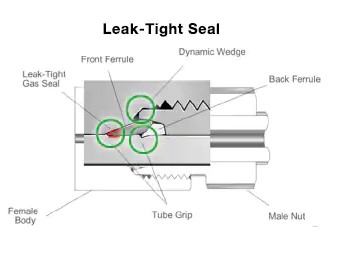

A ferrule is a small, ring-shaped piece of metal used to grip and create a leak-tight seal around the tube. Ferrule tube fittings usually comprise a fitting body, a ferrule—single or double, and a nut. When the nut is tightened, it creates compression between the tube and the ferrule, ensuring a secure connection and leak-tight seal.

The choice between single or double ferrule fittings mostly depends on the application and the operating condition of the fluid system. The table below makes a general comparison of single ferrule vs. double ferrule tube fittings.

Single Ferrule vs. Double Ferrule Tube Fittings |

||

|

Single Ferrule Tube Fitting |

Double Ferrule Tube Fitting |

|

|

Design |

This tube fitting uses a single ferrule to establish the tube's seal and grip. |

The fitting contains two ferrules—one creates the seal while the other supports grip.. |

|

Installation |

The ferrule compresses onto the tube while the tightening of the nut creates the seal. |

The back ferrule grips the tube, while the front ferrule creates a tight seal. |

|

Operating condition |

High-pressure flow tends to cause more vibrations than low-pressure flow does. Due to vibration, single ferrule tube fittings are more likely to lose their grip and sealing capabilities, causing the system to fail. So, these are not suitable for high-pressure conditions. |

Double ferrule fittings are suitable for high temperature and pressure conditions because two ferrules design ensures additional grip and a secure connection against system vibration and pressurization. |

Choosing the Right Ferrule Tube Fitting

Leaking connections is a major reason for failure in refinery tubing systems. While welds may be used in many cases, tube fittings can also provide a reliable connection, especially when dealing with factors such as vibration fatigue—welds crack, ferrules don’t. Ferrule tube fittings are versatile enough to provide an effective seal and grip with simple installation.

In particular, Swagelok’s dual ferrule tube fittings are designed to solve these fluid system challenges in refineries. These fittings feature:

- 316/316L stainless steel bodies that provide excellent resistance against corrosive fluids.

- Enhanced hinging-collecting action that provides robust tube grip and protection of the stress riser area by dampening the effects of vibration.

- Enhanced leak-proof sealing, suitable for even the smallest molecule gas systems.

- Live-loaded design easily handles rapid temperature or pressure changes.

Reliable Connections With Swagelok’s Tube Fittings

The safety and reliability of fluid system operation depends on the components in use. In the choice of single ferrule vs. double ferrule tube fittings, although the latter provides a more secure connection, the fitting selection should depend on the process condition and cost-effectiveness desired for the specific application.

If you want to learn more about the tube fitting solutions from Swagelok, you can explore these links on tube fitting training and tube fitting assembly. Also, check out our Swagelok® FK series fittings, the robust ferrule tube fitting that provides excellent grip and seal with easy and cost-effective installation options for medium pressure systems.

To find out more about how Swagelok Northern California can help you make a selection between single ferrule vs. double ferrule tube fittings for your fluid system installation, contact our team today by calling 510-933-6200.

About Morgan Zealear | Product Engineer, Assembly Services

About Morgan Zealear | Product Engineer, Assembly Services

Morgan holds a Bachelor of Science in Mechanical Engineering from University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration and Mechanical Efficiency Program Specification (API 682), and he is well versed in B31.3 Process Piping Code. Before joining Swagelok Northern, he was a manufacturing engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)