Share this

Skill: Swagelok tube fitting assembly, one inch and under

by Jeff Hopkins on 10/23/12 6:00 AM

Swagelok's two-ferrule design can be disassembled and reassembled. Here's how.

One benefit of using Swagelok tube fittings is that they can be disassembled and reassembled many times while retaining the leak-tight seal. Here's a demonstration:

Swagelok's flagship product is our tube fitting, designed to provide a leak-tight seal for pressures up to the suggested allowable pressure rating of the tubing. It is a two-ferrule, mechanical-grip, hinging-colleting type connection consisting of a fitting body, a nut, a front ferrule, and a back ferrule.

Tools for assembly

Manual assembly of the Swagelok tube fitting one inch and smaller is easy and simple. But make sure you have the right tools at hand:

- Two open ended wrenches (or one open-end wrench and a vise)

- Swagelok gap inspection gauge

- Tube cutter or a hacksaw

- File or a Swagelok deburring tool

- Marker

Proper tubing preparation is important. Two common tools used to cut tubing are the tube cutter and the hacksaw. Whichever one you use, the cutting creates burrs that must be removed using a Swagelok deburring tool or a file.

Now let’s take a look at one of the fittings. It is important to note that Swagelok tube fittings come to you completely assembled, finger-tight, and ready for immediate use. Don't disassemble the fittings prior to installation. Disassembly can result in dirt or foreign material getting into the fitting, which can interfere with sealing.

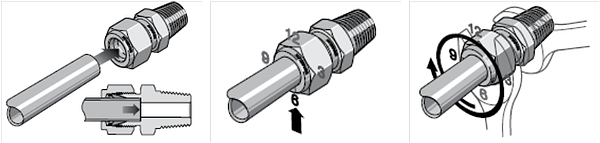

Assembly in three steps

The typical assembly is a three-step procedure. These instructions apply both to traditional fittings and to fittings with the advanced back-ferrule geometry.

First, fully insert the tubing into the fitting and against the shoulder. Then rotate the nut finger-tight.

Next, mark the nut at the six o'clock position. Marking the nut at six o'clock leaves no doubt as to the starting and ending positions.

Finally, while holding the fitting-body steady, tighten the nut one-and-one-quarter turn to the nine o'clock position. (For one-sixteenth-, one-eighth-, and three-sixteenth-inch, and two-, three-, and four-millimeter tube fittings, tighten the nut only three-quarters of a turn to the three o'clock position.)

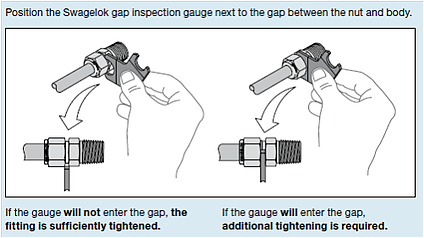

Swagelok's gap-inspection gauge makes it easy to check whether you have tightened the fitting enough on initial installation. To use the gauge, position it next to the gap between the nut and the body. If the gauge will not enter the gap, the fitting is sufficiently tightened. If the gauge will enter the gap, additional tightening is required.

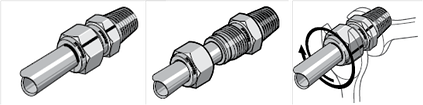

Multiple use

Before you disassemble a Swagelok tube fitting, always depressurize the system. Also mark the tube at the back of the nut and mark a line along the nut and fitting body flats. You'll use these marks to make sure you return the nut to the previously pulled-up position.

To reassemble, insert the tube with pre-swaged ferrules into the fitting until the front ferrule seats against the fitting body. While holding the fitting body steady, rotate the nut with a wrench to the previously pulled-up position, as indicated by the marks on the tube and flats. At this point, you will feel significant increase in resistance. Tighten the nut slightly.

Do not use the Swagelok gap inspection gauge with reassembled fittings. Also, do not mix or interchange parts with those of other manufacturers.

Get a closer look

For a closer look at Swagelok tube fitting design, pressure ratings, comparative advantages, and more, get our Swagelok Northern California Fittings Resource Collection. It puts all the best info in your hands, in one step—like the latest Installer's Pocket Guide, the Tube Fitter's Manual, the Tubing Data Sheet, essential catalogs, and more.

Introducing the Tube Fitting Assembly Toolkit

Introducing the Tube Fitting Assembly Toolkit

The Swagelok Tube Fitting Assembly Toolkit contains all the hand tools needed for the leak-tight, gaugeable, and safe installation of Swagelok tube fittings in our three most common sizes: 1/4, 3/8, and 1/2 in. Nestled in a locking hard case, you'll find Swagelok preswaging tools, tee wrench, ratchet wrench, tube cutter, tube deburring tool, tube gripper pad.

More articles like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)