Share this

Streamline Plant Maintenance With Tubing

by Jeff Hopkins on 12/18/19 9:00 AM

Save time and enhance system performance compared to hard pipe systems

"Swagelok tubing meets or exceeds industry standards in a wide range of sizes, forms, and alloys. Ultrahigh and high-purity stainless steel tubing preserves the cleanliness of your system."

- From Swagelok Tubing & Tube Accessories

Downtime is lost revenue. So when you need to service your steam turbine throttling valves or change out pilot solenoid valves in your electrohydraulic controls, you want to get in and out of the system quickly.

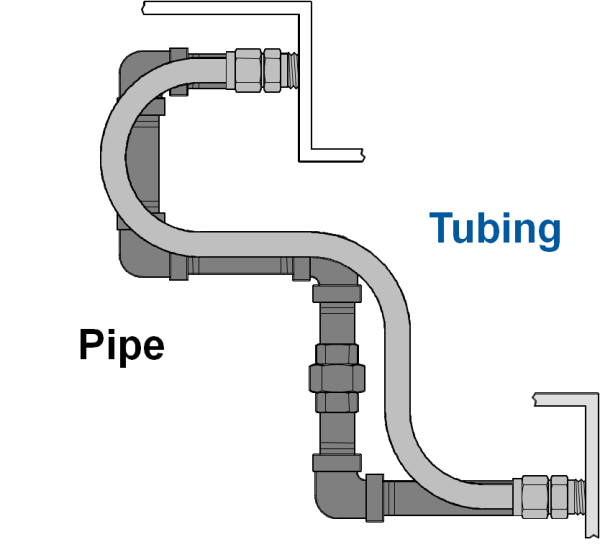

Unfortunately, you can't move quickly with hard pipe. Cutting, welding, and threading require a lot of time and labor. A better alternative may be stainless steel tubing.

Unfortunately, you can't move quickly with hard pipe. Cutting, welding, and threading require a lot of time and labor. A better alternative may be stainless steel tubing.

Most control systems in a plant depend on fluid delivery of one kind or another – steam, condensate, hydraulic fluid, chemicals, pressurized air, etc. And these fluids are delivered through piping systems, many of which are 2 inches in diameter or less. For these fluid systems, stainless steel tubing, instead of hard pipe, can greatly simplify installation and plant maintenance.

Compare and save

Imagine two teams of technicians building any typical configuration involving 90-degree turns and other complexities. One team works with stainless steel tubing, the other with hard pipe. The stainless steel tubing team probably would finish way ahead of the piping team, maybe even by hours. The tubing team won't even need to bring special contractors or welders to the plant floor. Your own technicians can be trained to manage the bending and assembly.

When it comes to fluid power efficiency, tubing wins again. Your electrohydraulic controls must be quick and responsive. But hard piping systems are inefficient by their very nature. Their 90-degree elbows create pressure drop. Each connection is a potential leak point. And threaded pipe fittings are likely to leak, especially if your system generates vibration or thermal expansion and contraction.

By contrast, stainless steel tubing is bendable to precise radiuses. You can create gradual sweeps, which minimize pressure drop. Swagelok tube fittings will not back off with thermal cycling or high vibration. You can further eliminate leak points with automated orbital welding. Orbital welds are just as strong as tube fitting connections, and you don't even need to own an orbital welder. They are available for rental through from Swagelok Northern California.

You can assemble permanent, welded connections in the instrument and control shop, then move the assembly to the plant floor and connect it with tube fittings. If the tube fitting connections are strategically located, then the system becomes modular.

Even if your plant produces severe vibration, you can bend the tubing into a hairpin or pigtail configuration, which can help to absorb the vibration. These solutions also work well in places where there is substantial thermal expansion and contraction.

Quick activation

Almost as soon as the last tube fitting is assembled, a tubing system is ready for service. There is no need to flush the system because assembly does not produce filings and chips like a hard pipe system does. These filings and chips from hard pipe can potentially clog the transducers on the pilot solenoid valves or otherwise undermine the performance of valves.

Wide application

Many systems in a plant can be made more efficient by switching from pipe to stainless steel tubing, including the chemical feed system, water sampling system, duel fuel systems, generator and lube oil systems, and hydrogen cooling for the generator.

Many systems in a plant can be made more efficient by switching from pipe to stainless steel tubing, including the chemical feed system, water sampling system, duel fuel systems, generator and lube oil systems, and hydrogen cooling for the generator.

Ask yourself, how critical is the efficiency of this system? If it were faster, more accurate or consumed less power, how significantly would that affect overall plant efficiency and revenue? How frequently is maintenance required on the system? If maintenance could be performed more quickly and easily, how significant would that benefit be to your plant?

Just ask

Swagelok Northern California has a great deal of exposure to all aspects of fluid system design and engineering. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)