Share this

Swagelok in Action: Thermocouple Assembly for Chemical Manufacturer

by Jeff Hopkins on 3/8/17 8:30 AM

The latest case study in the Swagelok in Action series features our collaboration with a chemical and specialty component manufacturer in the semiconductor industry.

Since our founding in 1947, Swagelok has been manufacturing high-quality filters, fittings, connectors, valves, assemblies, and other related products. Beginning in 2005, we also began offering our unique Assembly Solutions services.

Working directly with clients, our dedicated team of designers and engineers will help you design a custom assembly solution suited to your specific application. Over the years, we’ve assisted clients design assemblies of all shapes, sizes, and complexities in a range of industries.

Assembling a Thermocouple

One of our clients — a manufacturer of chemicals and specialty components for use in the fast-moving semiconductor industry — required a special mount for a thermocouple.

Thermocouples are an integral component in many different devices, from household thermostats to highly advanced industrial monitoring technologies. A thermocouple is made of two wires, each made of a different metal, that use the thermoelectric effect to generate a temperature-dependent voltage, which can then be translated into a temperature reading.

Our client required the thermocouple for several steps of the semiconductor production process; it also needed to be able to handle cold trap applications. To monitor temperatures during these processes, the customer required a specific type of thermocouple mounting assembly — which didn’t yet exist.

Engineering Solutions

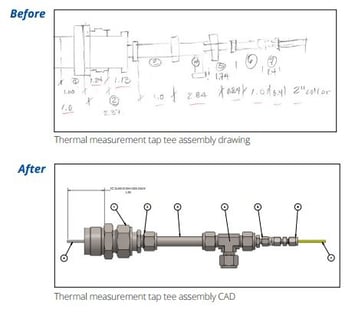

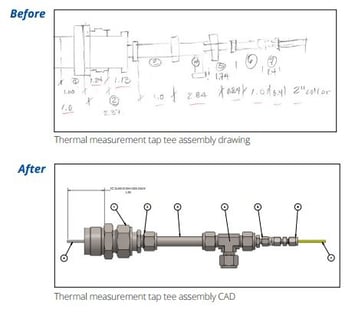

When the client approached our Swagelok Assembly Solutions team, they had little information to provide and only a rough pencil sketch of the required mounting assembly, which needed to be designed and manufactured in only two weeks.

After transferring the pencil sketch to a CAD plan, our Swagelok Assembly Solutions team refined and perfected the assembly design. Our team was able to manufacture and deliver not one but four of the fully customized assemblies.

Working with Swagelok Assembly Solutions

When working with Swagelok Northern California’s Assembly Solutions team, you’ll get the assembly you need, but you’ll also get a true partnership. At Swagelok, we’re dedicated to providing timely, efficient solutions for our all clients, no matter how complex their needs.

To learn more about our Assembly Solutions capabilities and how we’ve helped other companies with their unique projects, download our free eBook, “10 Assembly Solutions Case Studies.”

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)