Share this

Switching From Gland Packing to Mechanical Seals: Surprising Benefits for California Refineries

by Paul Lesnau on 10/1/20 8:45 AM

Decades-old refineries in the California Bay Area still have numerous pumps that use gland packing to control leakage. In many instances, the age of the pump and seemingly minimal maintenance costs might convince refineries to forgo switching from gland packing to mechanical seals. While that plan may seem reasonable at the moment, in the long run, mechanical seals matched with the proper seal support systems provide a far more reliable and safer method of managing pump leakage.

Here’s the bottom-line: There are several key factors and some of the lesser-known issues that you may not be considering in your cost-benefit analysis of making the switch. And refineries like yours contend with these issues more often than you think when maintaining gland packings. Let’s start with the biggest challenge—generational turnover and the skills loss it causes—since it leads to many of the other hidden costs.

Gland Packing Reliability Depends on Hands-on Maintenance Experience

As maintenance personnel retire, fewer technicians have the skills and experience to properly install, maintain, and replace gland packing seals. As a result, improper maintenance can run up the costs of maintaining gland packing seals.

Replacing gland packing seals requires skill and experience that can’t be aren’t necessarily learned overnight. Years of experience are required to competently select the proper replacement gland packing. This requires maintenance personnel to have an understanding of factors such as stuffing box dimensions, process fluid characteristics, process fluid temperature, pumping pressure, surface speed of the shaft, and performance characteristics of the various gland packings. You don’t necessarily learn this in engineering school—it takes hands-on experience.

If gland packing rings are not pre-cut or pre-formed, cutting the rings to fit using a skive or butt joint takes practice. Failure to make a sharp, clean cut and join the ends is sure to undermine the seal reliability.

Gland packing tightening is also an art. Uneven tightening will result in uneven compression and wear. Excessive tightening does largely prevent leakage but creates not-so-obvious problems that can slowly increase costs, such as:

- Rapid shaft wear that results in costly downtime associated with shaft replacement

- Lower motor/drive efficiency that increases energy costs

- Frequent replacement of worn gland packing

Less-experienced maintenance professionals may be challenged to properly diagnose the variety of problems listed below that cause gland packing seals to fail prematurely.

| Symptom | Causes |

| Burnt gland packing | Packing ring cannot tolerate shaft surface speed |

| Soft packing | Chemical reaction to process fluid |

| Gland packing extrusion | Improper clearances between stuffing box, gland packing, lantern ring, and shaft |

| Worn or fractured gland packing fibers | Damaged shaft surface or incompatible fibers |

Fewer maintenance personnel having the required skills is a good reason to consider switching from gland packing to mechanical seals. There are a few more reasons to make the change.

4 More Reasons to Switch From Gland Packing to Mechanical Seals

From a mechanical perspective, gland packing seals are simple. Yet, with ongoing maintenance requirements and the loss of skilled technicians, in many instances, gland packing seals come up short. Mechanical seals offer a better alternative. Here’s some more reasons that you should consider switching from gland packing to mechanical seals.

#1 Solutions Tailored to the Specific Pumping Requirement

Mechanical seals and matching seal support systems offer a wide range of designs and configuration options to address specific pumping conditions. Are you working with high temperature, high pressure, process fluids with particulates? There’s a choice of mechanical seals and seal support systems for each of these. Seal support systems can be configured with different options to closely match mechanical seal and pumping process requirements. In comparison, gland packings offer nowhere near the ability to meet the spectrum of specific pumping requirements.

Mechanical seals and seal support systems also eliminate the risk of process fluid leaking into the coupler or motor bearings, degrading performance and leading to eventual bearing failure.

#2 Durability and Reliability

Improperly selected or installed gland packings are prone to premature failure, requiring frequent replacement, accompanied by downtime. Each replacement adds to maintenance costs and lowers process efficiency. In contrast, with the proper seal support systems, mechanical seals have an expected lifecycle of at least three years—and often longer—leading to lower maintenance costs and downtime.

#3 Superior Protection Against Leakage

It’s your job to be vigilant about leakage of process fluids that present a health or safety risk that would subject the refinery to Cal/OSHA or BAAQMD sanctions. Mechanical seals, and dual seal arrangements in particular, provide a significantly higher level of protection against this risk compared to gland packings. Mechanical seals and seal support systems also eliminate the risk of process fluid leaking into the coupler or motor bearings, degrading performance and leading to eventual bearing failure. Two plan examples illustrate the superior protection provided by mechanical seals and seal support systems.

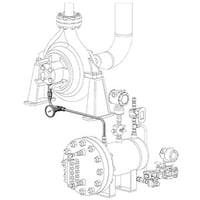

API Plan 53A Barrier Fluid Seal Pot Pressurized by Nitrogen

|

Failure of the inboard or atmospheric side of a dual seal is immediately recognized by a change in seal chamber pressure, allowing operations to shut down the process and prevent catastrophic leakage. |

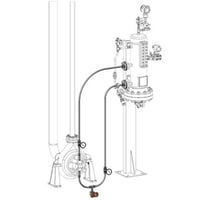

API Plan 75 Condensing Leakage Collection

|

|

In pumps where process fluids condense between seals at ambient temperatures, this plan routes leakage from the inboard seal to a reservoir via a seal drain port and routes any vapor to flare. Excessive liquid inner seal leakage is detected by a level transmitter. Excessive gas leakage is detected by a pressure transmitter located on the tubing connected to flare. |

#4 Lower Maintenance Costs

Gland packing seals require frequent inspection, continual maintenance, and frequent replacement. Those activities increase maintenance costs. In contrast, the superior design of mechanical seals and enhanced reliability provided by the right mechanical seal support system can significantly lower maintenance costs.

Instrumentation and transmitters incorporated into the seal support system providing continuous performance metrics and immediate indications of problems. These capabilities reduce the need for frequent inspections and help maintenance personnel proactively remedy nascent problems.

Make the Switch With the Help of Local Expertise

Unless you have significant in-house expertise regarding mechanical seal selection and seal support system configuration, it’s best to seek the guidance and expertise of local suppliers.

Your local mechanical seal supplier will advise you on the appropriate mechanical seals to replace gland packings. Then contact us at Swagelok. Our Field Engineers will meet you on-site to gather specific information about your requirements, taking into consideration process characteristics, recommended mechanical seal, and existing pump infrastructure.

Using that information, we’ll create detailed design drawings and technical specifications for each of the pumps switching to mechanical seals. Upon your approval, we’ll fabricate, assemble, and test each seal support system following our ISO 9001 quality management best practices. With an extensive inventory of top-quality components, we’ll quickly turn your designs into solutions backed by the best Lifetime Warranties in the industry.

To learn how Swagelok Northern California can help you make the switch from gland packing to mechanical seals by providing expert on-site consultation, design, and fabrication of seal support systems, contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization focused within the pneumatic and hydraulic industry where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)