Share this

The Benefits of API Plan 32 Design Build For Bay Area Refineries

by Paul Lesnau on 9/30/20 8:45 AM

Day-to-day in Bay Area refineries, you are likely to deal with installations of nearly every API 682 Seal Plan, from the simple API Plan 11 to the more complicated API Plan 55. Although the functions and applications for each of these plans is well documented, successful implementation often requires far more than just selecting a plan from a supplier catalog.

When you need API plan 32, for instance, you might be tempted to take the project in-house but there are many factors to consider. Let’s start by taking a look at what API Plan 32 provides to highlight some of these factors. I think you’ll agree that, in many cases, a Design-Build is the way to go.

Getting to Know API Plan 32 Basics

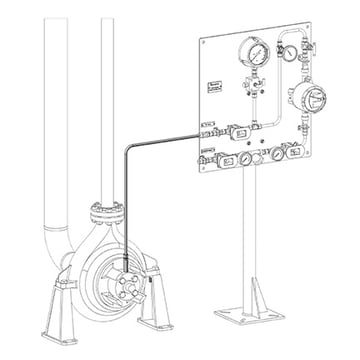

When the process fluid cannot be used to provide the required flush and lubrication, your go-to is API Plan 32. It delivers clean, lubricating flush fluid to a seal chamber from an external source. Flush fluid must be delivered one bar or higher above the seal chamber and requires a close-clearance throat bushing to limit the amount of flush fluid migrating into the process fluid. So, the flush fluid must be compatible with the process fluid.

API Plan 32 is particularly applicable for the high-temperature and particulate processes described in the table below. An additional advantage of API Plan 32 is that it can supply a cooling flush to both horizontal and vertical pumps.

| Application | Reason |

| High-temperature process fluids | A cooling flush is required to maintain a proper seal chamber environment. |

| Process fluids contain particulates or contaminates | A clean flush prevents degradation of the mechanical seal by removing solids or damaging fluid. |

| Process fluids have poor lubrication characteristics | A clean flush provides the required seal lubrication to prevent degradation of the mechanical seal. |

This seems pretty straightforward, right? Well, there’s more to it—especially for Bay Area refineries. Discounting the importance of a single factor or compromising a component for the sake of cost could actually lead to higher costs down the line. More frequent maintenance or seal failure that could result in Cal/OSHA or BAAQMD sanctions can be avoided with a rigorous design process.

That’s why you should examine the benefits of a Design-Build.

API Plan 32 Design-Build Considerations

To obtain the optimum performance from the seal support system, several other factors need to be considered and that may make you lean toward a Design-Build, even for API Plan 32. I’ll start with the key factors that influence the final API Plan 32 design in the table below.

| Design Factor | Effect on API Plan 32 Design |

| External flush source must provide a continuous and reliable flow | The shop water pressure can vary, occasionally falling below required seal chamber pressure. An external pump and reservoir may be needed to maintain proper pressure. |

| Flush must be delivered at 15 psi to 25 psi (1 bar to 1.7 bar) above stuffing box pressure | Configure the pressure regulator to provide proper pressure, accounting for throat bushing dimensions and flow of flush into process fluid. |

| High-temperature fluids require flush flow to provide adequate cooling | Ensure external source can consistently deliver required flush flow and temperature. Implementation may require retrofit of existing infrastructure. |

| Shop water may require filtering to prevent clogging of the flow control valve | Include filter or strainer, with optional bypass loop to ensure supply of clean flush. |

| Flush fluid must be compatible with the process fluid | If using a flush other than water, additional configuration—pump, reservoir, piping—may be required to flush the source. |

Face it, there’s a lot to consider when designing a solution. That’s why you can’t trust the specifics to just any engineer—in-house or out. You need one who can understand the full picture of what your refinery’s process requires to get the full benefit and reliability from API plan 32.

Look to Experts for API 32 Design-Build Efficiency

A refinery looking to install a new API Plan 32—or update or replace—might have the required skills to take on the task, but the required personnel are likely spread across several different job titles. There’s a more efficient way to get the job done. A mechanical seal systems supplier can help refineries to design, build, test, and deliver seal support systems tailored to refinery requirements.

When it comes to implementing an API Plan 32 design and build, a skilled field engineer should conduct an on-site assessment to:

- Understand the process—fluid characteristics, pump rate, mechanical seal design, and plant infrastructure

- Evaluate the source, quality, and reliability of the flush fluid source

- Determine how existing infrastructure (seal support system upgrade or replacement) or planned infrastructure (new installation) will affect API Plan 32 design

Based on the assessment, the field engineer will then design the API Plan 32 and provide detailed engineering drawings and technical specifications for your review. Customizations incorporated into the design to enhance reliability and efficiency may include high-point vents to clear entrapped air, low-point drains to purge flush fluids during scheduled maintenance, or bypass loops to provide a continuous supply of flush fluid when a filter is replaced or cleaned.

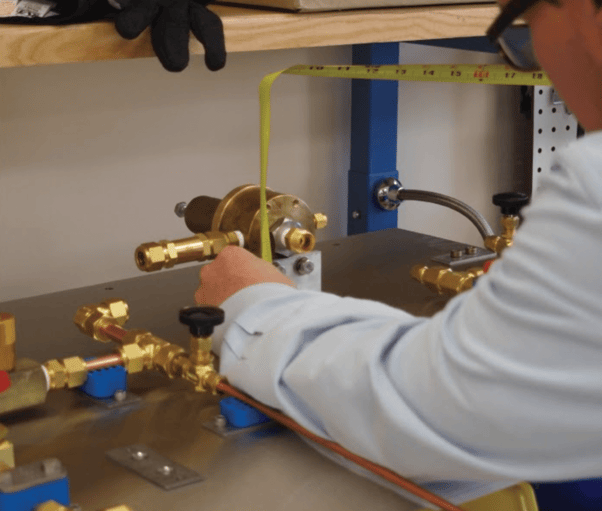

Upon approval of the design, certified technicians will then build the API Plan 32 according to specifications.

Yes, you might be tempted to tackle an API Plan 32 design-build project alone, but consider this: An experienced, local seal support systems supplier will design the solution tailored to your specific process needs, build the system with the highest quality components, and significantly reduce delivery time.

Locally-Built API Plan 32 Reduces Delivery Time

Swagelok’s certified technicians adhere to the best practices and recommended components specified by API 682. We also follow ISO 9001 standards in applying fluid system expertise in building and testing mechanical seal support systems. Systems are built locally, from Swagelok’s extensive inventory of quality components, thereby reducing the design-build-deliver cycle. Prior to delivery, all systems are thoroughly tested to ensure reliability, ease of maintenance, and safe operations. All Swagelok products are backed by one of the best Lifetime Warranties in the industry.

With Swagelok, you receive the quality, reliability, and ongoing technical support you deserve.

To find out more about how Swagelok Northern California can design and build the API Plan 32 for your specific process requirements, contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization focused within the pneumatic and hydraulic industry where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)