Share this

The right valve for controlling flow direction? Check.

by Neil Ide on 10/27/16 9:00 AM

Also known as non-return valves, they’re more complex than you might think.

Tip: Get our Valve Selection & Sizing Essentials Collection. Includes Swagelok Valve Sizing Technical Bulletin, Matching Valve Type to Function: A Tutorial in Valve Selection, and Valve Selection Worksheet.

Tip: Get our Valve Selection & Sizing Essentials Collection. Includes Swagelok Valve Sizing Technical Bulletin, Matching Valve Type to Function: A Tutorial in Valve Selection, and Valve Selection Worksheet.

Where and when chemical mixing occurs is often critical, and it rarely happens without some sort of check valve on the lines. As chemistry professor Frank Westheimer once said, "a month in the laboratory can often save an hour in the library.”

Preventing upstream mixing

Whether the finished products are petrochemicals, biopharmaceuticals or household cleaners, they’re made by mixing chemicals. Where and when the mixing occurs is often critical, especially if the mixing results in a chemical reaction. And it rarely happens without some sort of check valve on the lines to prevent the chemicals from mixing upstream.

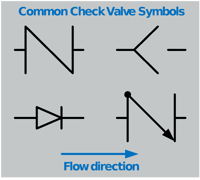

Check valves (also called non-return valves) come in a variety of types and are used in all sorts of applications beyond chemical processing. Their function is simple: Stop fluid from flowing in the reverse direction. How they do that, however, can get complex.

Check valves 101: the basics

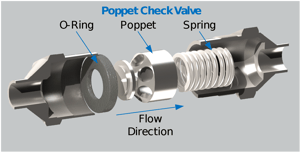

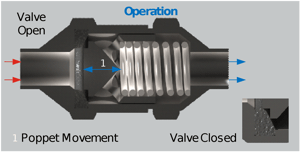

Swagelok makes two basic types of check valves: poppet check valves and lift check valves. Poppet check valves have a spring-loaded valve poppet that is compressed against an elastomeric seal. Fluid flows through when there’s enough upstream pressure to overcome the spring pressure, shifting the poppet off the closed seat.

Swagelok makes two basic types of check valves: poppet check valves and lift check valves. Poppet check valves have a spring-loaded valve poppet that is compressed against an elastomeric seal. Fluid flows through when there’s enough upstream pressure to overcome the spring pressure, shifting the poppet off the closed seat.

The amount of required pressure to open the check valve is called the cracking pressure. This type of action is very similar to the function of a proportional relief valve.

The amount of required pressure to open the check valve is called the cracking pressure. This type of action is very similar to the function of a proportional relief valve.

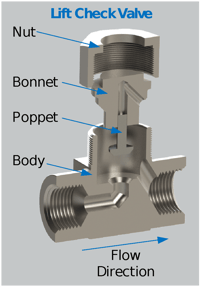

Lift check valves depend on gravity. In a lift check valve, the poppet is positioned so that forward flow through the valve lifts the poppet off of the valve seat. When higher pressure is felt on the outlet of the check valve, gravity pulls the poppet shut with the assistance of the fluid.

Since there is no spring on the poppet, it cannot fully seal and no elastomer material is required for the seat. A lift check valve can only restrict flow, not stop it completely.

Crack and reseal

In poppet check valves, cracking and reseal pressures determine when the valve opens and closes. Remember, cracking pressure (PCr) is the minimum pressure differential needed in the forward direction to open the check valve.

Reseal pressure (PRs) is the minimum pressure differential in the reverse direction that is required to reseal the check valve. Until PRs is reached, the check valve will not shut off under reverse flow conditions.

Reseal pressure (PRs) is the minimum pressure differential in the reverse direction that is required to reseal the check valve. Until PRs is reached, the check valve will not shut off under reverse flow conditions.

Failure to meet PRs is one of the most common errors when a poppet check valve is used. (The other common error is installing them backward.)

Because resealing is aided by a spring, the lower the cracking pressure the higher the reseal pressure required. If you are using a 1/3 PSI cracking pressure check valve, the reseal pressure can be as high as 20 PSI backpressure before the valve shuts off.

Failing to meet the reseal pressure means the check valve may bleed fluid backward, which can be downright dangerous in some systems.

The power of two

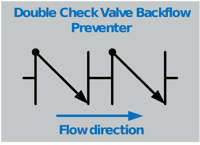

So what do you do if you can’t tolerate any backflow through the check valve before it shuts off? The answer is surprisingly simple: put two check valves in series. The combination is called a backflow prevention device.

You might not realize how often you see backflow prevention devices. Next time you go past a building, look for a pipe coming out of the ground with a couple of valves and then returning right back to the soil.

On public water systems, backflow prevention devices protect our drinking water from lawn sprinkler systems that add fertilizer to the water. Backflow prevention devices also protect us from fire sprinkler systems that use anti-freeze.

Code-compliant backflow devices have a little bit more to them than two check valves in a row; however, adding a second check valve in line with the first changes the functional dynamic of the valves and together you get a reseal pressure that is effectively 0 PSID.

At your disposal

If you are currently engaged in a gas or liquid system design and want some expert advice, get in touch. There is a good chance that we’ve already encountered a problem you may be struggling with, maybe even in a different industry.

At Swagelok, we pride ourselves as a high performance resource for fluid systems technology, and serving multiple industries gives us a lot of exposure to the troubles of others. As chemistry professor Frank Westheimer once said, “a month in the laboratory can often save an hour in the library.” Contact us the next time you start heading to the lab to solve a problem.

Help me choose

Because of the many materials, products, and technologies available from Swagelok, it may be a challenge to quickly identify the very best one for your need. Swagelok Northern California professionals are standing by to help.

Because of the many materials, products, and technologies available from Swagelok, it may be a challenge to quickly identify the very best one for your need. Swagelok Northern California professionals are standing by to help.

Build it for me

Outsourcing assembly to Swagelok Northern California enhances safety, often lowers total cost, simplifies logistics, and shortens turn times. And, learning about your best options costs nothing.

Outsourcing assembly to Swagelok Northern California enhances safety, often lowers total cost, simplifies logistics, and shortens turn times. And, learning about your best options costs nothing.

About Neil Ide

Neil has always been fascinated by the technical side of things. When he grew up, Ide served on Navy submarines as a nuclear plant operator. At Bloom Energy, a startup that makes power generation systems based on fuel cells, he worked with the R&D science teams to develop and build test equipment. At Swagelok Northern California, he built up the assembly solutions program to handle more complex assemblies and created the popular Customer Briefing Center in our Fremont office.

More articles like this

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)