Share this

Which Grab Sample Panel Options Work Best For You?

by Jeff Hopkins on 12/26/18 9:00 AM

Swagelok offers 15 standard designs, that can be configured to your specific needs

"Swagelok's basic layouts were really helpful. Then we made modifications to meet our precise needs."

- Lab Lead, Chem/Refining (US)

Two system types

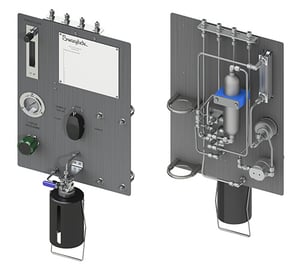

When you need to quickly get repeatable and representative samples from your process line, you need a grab sampling system. Swagelok grab sampling systems satisfy gas and liquid non-slurry sampling service in a consistent, reliable package. Two system types allow for capture into one of two types of containers — pressure containing metal cylinders as found in the Grab Sample Module (GSM) or non-pressure containing glass or polyethylene bottles as found in the Liquid Only Sampling Module (GSL).

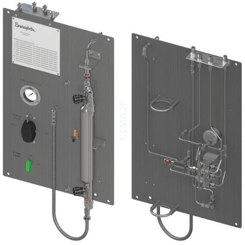

Grab Sample Modules (GSM) Liquid-Only Sampling Systems (GSL)

Five standard designs in action

The next question is which grab sampling system configuration is right for you. Let's start by checking out five basic setups in action.

First, here's a 90-second video showing how our standard gas panel (GSM-G-1(-N)) works. You'll see how to attach the sample cylinder, how the sample flows when you open and close the valves, and how to disconnect the cylinder. We have a standard liquid sampler without purge (GSM-L-1(-N)) and a simple liquid sampler without purge (GSL1). This is our Standard Gas Sampler without Purge (GSM-G-1(-N)) in action.

This is our Standard Liquid Sampler without Purge (GSM-L-1(-N)).

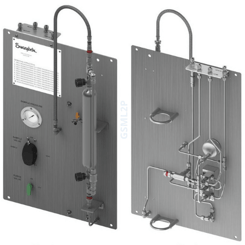

The next video shows the same standard setup plus the ability to purge the line after taking the sample, but before detaching the sample cylinder. We offer a standard liquid sampler with purge (GSM-L-1(-P)), a simple liquid sampler with purge (GSL2), and and a liquid sampler with back purge (GSL5). This is our Standard Gas Sampler with Purge (GSM-G-1(-P)).

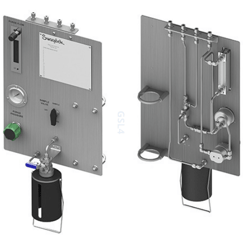

Perhaps you don't want to stop the flow of fluid through your system while you are taking the sample. In that case, our Continuous Flow Panel might be what you're looking for. We have continuous flow liquid samplers without purge (GSM-L-2(-N) and GSL3). This is our Continuous Flow Gas Sampler without Purge (GSM-G-2(-N)).

Do you need the continuous flow setup plus the purge feature? We have that in standard gas (GSM-G-2(-P)), standard liquid (GSM-L-2(-P)), and liquid only (GSL4).

Standard Gas (GSM-G-2(-P) Standard Liquid (GSM-L-2(-P) Liquid Only (GSL4)

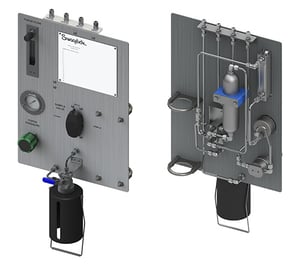

Fixed volume samplers

Fixed volume sampling prevents overfilling of the sampler. A sample is drawn into a fixed volume reservoir, held, and then dispensed into the sampler. This requires a sample bottle that is larger

than the fixed volume reservoir. We offer two liquid only designs, Fixed Volume with Purge (GSL6) and Fixed Volume with Continuous Flow and Purge (GSL7). Continuous flow is recommended for samplers installed directly in the sample stream, in a fast loop, or where long sample transport lines are used.

Fixed Volume with Purge (GSL6) Fixed Volume with Continuous Flow and Purge (GSL7)

This is our Fixed Volume with Continuous Flow and Purge (GSL7) in action.

Detailed variations

Every GSM is available in either 2- or 3-valve configurations. This allows for simultaneous control of fluid routing, reducing the number of sequencing steps required to draw a sample.

Once you have picked a basic panel design, you can customize it further. Swagelok Northern California makes the panels right here in the Bay Area, so you'll be talking with the people who will do the customization work. We can work with your team to:

- Substitute comparable Swagelok and non-Swagelok (non-competitive) products

- Add products within the existing schematics – sample coolers, flowmeters, shut-off valves, drain valves, etc.

- Make changes in layout including structural changes/additions – panel/bracket materials, enclosures, etc.

- Convert to larger/smaller tube size (or metric)

- Alternate materials of construction

- Adjust flow/pressure drop calculations (and make changes based on results)

- Change sizing of sample coolers/heaters and enclosure heaters (using vendors’ applications engineering)

Case study

As you can see in this case study, Swagelok's experience includes helping Imtech Analyser Systems, one of the largest technical services providers in the United Kingdom and Ireland. Imtech won a contract that gave it only 12 months to design, engineer, and build 18 analyzer houses with 250 sampling systems for the oil and gas industry. Swagelok found a solution.

Here to help

Whether you need one Grab Sample Panel or many, you need only one supplier: Swagelok Northern California. We'll adapt the design to meet your needs, assemble it, test it, give the entire assembly a single part number, and back everything with the Swagelok Limited Lifetime Warranty. All it takes to start the process is a call to 510-933-6200 or ask for help through our website.

Grab Sampling Systems Application Guide

More like this:

- Good Orbital Welding Still Relies On Human Choices (blog article)

- Beyond Basics: Swagelok's Advanced Class In Orbital Welding (blog article)

- Swagelok technical articles on analytical instrumentation (section of this site)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)