Share this

Be Flexible: Hose Is Great For Many Applications

by Jeff Hopkins on 7/17/19 1:21 PM

It's fast, it's flexible, and can come with a wide variety of end connections

"When you go to vacuum in the airlock and you take the hose off the front of your space suit, there's a little bit of water in there, and you can see that sublimate and ice crystals form and fly away. My thought at that moment was, 'Oh, we are not kidding at vacuum here; we are really in space"

- From Kathleen Hallisey Rubins, a NASA astronautet

Flexible hose may be one of the most under-used components in power plant, refineries, and other general industrial and manufacturing environments. Many technicians and engineers don’t realize how far hose technology has come. Now, with the latest advances, you can use hose in many places historically limited to tubing or pipe.

The principal benefit of hose is easy installation and easy replacement of adjoining components like valves. It’s just a lot easier to work with hose than with rigid tubing or hard pipe because there is no bending, welding, or fitting. As a result, you will save a lot on your labor costs. Installing it takes a matter of seconds – minutes at most.

Hose is especially appropriate for short connections between movable parts, parts in high vibration, or parts that need to be frequently connected and disconnected.

In power plants, refineries, and other general industrial and manufacturing environments, that makes hose an excellent choice for:

- Compressed and instrument air applications

- Connections to compressors, pumps, or other devices that cause vibration

- Connections to pneumatic actuators on large control valves

- Chemical tote offloading equipment

- Hydraulic and lube oil applications subject to vibration

- Pressurized gas delivery from tanks and cylinders

- Sample analysis systems that draw fluid from process lines

- Natural gas, diesel, or liquid fuel handling applications

What's in a Hose?

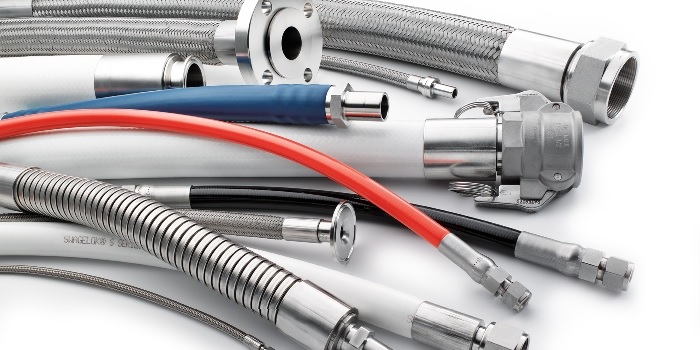

Typically, hoses consist of a core, reinforcement, covers, and end connections (Figure 1). Core materials may be metal, fluoropolymer, thermoplastic, or rubber. Many power plant applications employ stainless steel cores, which offer corrosion resistance and high-temperature compatibility – up to 850˚F (454˚C).

Reinforcement layers – often stainless steel woven braid – improve pressure containment and flexibility. With stainless steel braid, hoses available from Swagelok can manage pressures up to 3500 psig. Stainless steel braided reinforcement layers also prevent easy cutting – whether accidental or purposeful.

In semiconductor fabs, a silicone cover and insulation is often added in high-temperature applications to greatly reduce the likelihood of burns on contact.

Hoses can be fitted to a wide range of end connections, including tube adapters, tube fittings, VCR metal gasket face seal fittings, VCO O-ring face seal fittings, swivel fittings, NPT pipe threads, pre-swaged nuts and ferrules, tube butt welds, flanges, Kwik-Clamps, cam and groove, tube stubs, and more.

When Should You Use Hose?

There are many places where hose pays for itself very quickly.

Connections Requiring Complex Tube Bending: Tube bending is not difficult, but it does require some tools and training. If you don't have them, it may be advisable to go with hose. Sometimes a replacement part does not have the same dimensions as the original, and the original section of tubing or pipe does not quite align with the new connections. You can sidestep frustration with hose.

Applications with Severe Vibration: Hose can manage vibration stress better than tubing, especially under high pressure. Frequent vibration may stress tubing to the point of fracturing. A run of hose can dampen vibration between the source and the rest of the tubing assembly. All you need is an end connection that can handle vibration. For example, Swagelok tube fittings are designed not to leak with vibration.

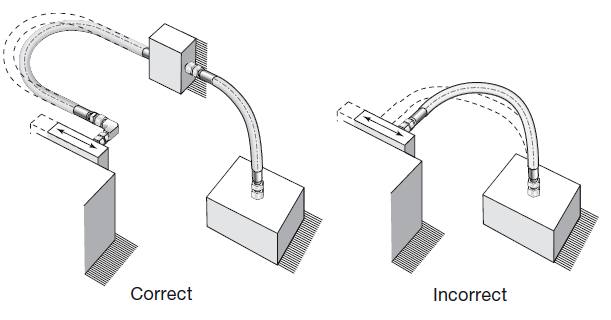

Temporary Connections: Hose is an excellent choice for water sampling, chemical sampling for analysis, or for offloading chemicals from totes. It bypasses alignment issues associated with rigid pipe or tubing, and it can attach with a cam-lock or quick-connect (Figure 2).

Moving Parts: The pneumatic actuators on some large control valves move up and down and therefore require a flexible connection to the compressed air source. An example would be control valves for oxygen fuel dampers. There are many other such applications in a power plant or refinery.

Parts Requiring Frequent Replacement or Servicing: When connected with Swagelok tube fittings, hose can be disassembled and reassembled with the turn of a wrench. Gas turbine inspections, for examplel require frequent assembly and reassembly of components, and hose makes this easier. If the hoses need to be changed out, it's a relatively simple process. You don't have to worry about an alignment issue.

Get it quickly

Swagelok hose is available in custom lengths up to 100 feet, in diameters 2 inches and under, and with a wide variety of end connections.Standard sizes and end connections ship within 24 hours.

With the proper selection of material options, hoses are completely dependable in a wide range of pressures and temperatures.

Just ask

Swagelok Northern California has a great deal of exposure to all aspects of fluid system design and engineering. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)