Share this

FAQ: What's the temperature rating of a Swagelok tube fitting?

by Jeff Hopkins on 5/14/14 11:15 AM

A lot has to do with the materials used in the tubing and the fittings. But that's not all.

In a When Will It Burst? video, we discuss two factors that require you to derate the working pressure of tubing. One of the factors is temperature. Heat and cold can change the performance of some fluid system components. When it comes to Swagelok tube fittings there are a few factors to keep in mind when tubing and fittings are being used at temperatures higher than 100°F (37°C) or below -20°F (-28°C).

ANSI Piping Codes

Temperature limits of most fitting and tubing materials are listed in ANSI Piping codes, including specific conditions regarding tubing materials and methods of manufacture. Steel, for instance is good up to about 375°F, while aluminum and copper top out at about 400°F. To perform under really high temperatures, it takes something like 304 stainless steel (800°F), alloy C-276 (1000°F), or 316 stainless steel (1000°F).

Tensile strength & temperature

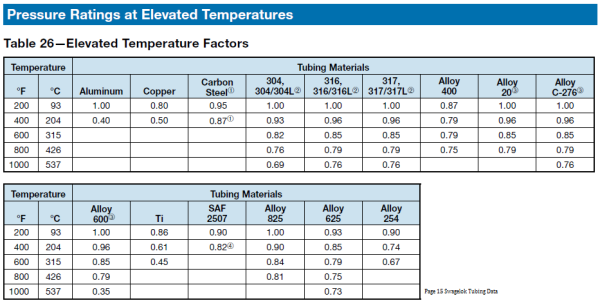

As the temperature increases, the tensile strength of metal decreases. So the higher the temperature, the lower the allowable working pressure of tubing. Let's take the 316 stainless steel tubing mentioned above. At 400°F the allowable working pressure is only 96 percent of the pressure allowed at 200°F. When the temperature climbs to 1000°F, the allowable working pressure drops to only 76 percent.

To determine allowable working pressure at elevated temperatures, multiply allowable working pressures by the derating factor.

Example: Type 316 stainless steel 1/2 in. OD 3 0.035 in. wall at 1000°F

- The allowable working pressure at –20 to 100°F (–28 to 37°C) is 2600 psig (Table 3, page 4 of the Swagelok Tubing Data sheet).

- The elevated temperature factor for 1000°F (537°C) is 0.76 (table above): 2600 psig 3 0.76 = 1976 psig.

- The allowable working pressure for 316 SS 1/2 in. OD 3 0.035 in. wall tubing at 1000°F (537°C) is 1976 psig.

Choice of alloy

When the temperature gets high enough, some fluids turn from liquid to gas. In those circumstances, it's important to make sure the tubing has the minimum wall thickness recommended for gas service.

It is particularly important to use the same alloy for both the tube fitting and the tubing so that thermal coefficients are the same. For example, you could run into problems if you put a 316 stainless steel fitting on alloy 400 tubing. As the temperature rises, the stainless steel would increase in size at a greater rate than the alloy tubing. The fitting would become loose on the tubing.

On the other hand, if an alloy 400 fitting is put on stainless tubing and raised to a high temperature, the joint becomes tighter. However, the stainless steel tubing increases in size at a greater rate than the alloy 400 fitting and may yield the fitting, and a leak could result when the temperature comes back down.

Chilling out

Materials are just as important to consider when the system has to work at extremely low temperatures. In general, plastics and elastomer materials usually are not good choices. Plastic components used as sealing members at room temperature will shrink markedly when temperatures are lowered, causing leakage. Many plastics also have some porosity, which allows water absorption. Water will solidify when temperatures are lowered and make the tube or fitting material brittle. Most elastomers harden at low temperatures and may crack.

The most commonly used materials in cryogenic piping systems are aluminum and austenitic stainless steel. Alloy 600, alloy 400 and titanium also work well for some applications. Once again, it's not a good idea to mix materials.

Always use a tube thickness recommended for gas service, even if the fluid is a liquid at ultra-low temperatures. If the system is ever brought up to room temperature, the fluid will become a gas.

Product test reports

We have tube fitting performance product test reports for various temperature conditions including high temperature and low temperature cycling and cryogenic service. These tests will give you an idea of how different Swagelok tube fitting perform perform at temperature extremes.

Please note that the tests were done in a lab, which can't duplicate the variety of actual operating conditions in the field. Temperature ratings depend on application and installation methods, cycle life required, and other variables. You can download the tube fitting performance product test reports here:

Help me choose

Because of the many materials, products, and technologies available from Swagelok, it may be a challenge to quickly identify the very best one for your need. Swagelok Northern California professionals are standing by to help.

Because of the many materials, products, and technologies available from Swagelok, it may be a challenge to quickly identify the very best one for your need. Swagelok Northern California professionals are standing by to help.

Build it for me

Outsourcing assembly to Swagelok Northern California enhances safety, often lowers total cost, simplifies logistics, and shortens turn times. And, learning about your best options costs nothing.

More articles like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)