Share this

Choosing Among Mechanical Seal Support Barrier Types Doesn’t Have to Be Complicated

by Paul Lesnau on 6/4/20 8:45 AM

A petrochem refinery is a complex place. There can be an ever-changing variety of operating modes that send different intermediate feedstocks through the units. As some crude stocks have changed and gotten heavier, especially in California Bay Area refineries, not all seal systems have kept up. All of this can add up to a variety of problems with your pumps and their mechanical seal support systems.

When you go to upgrade or replace these systems, you’ll find a dizzying array of different API seal plans and barrier fluids that can be intimidating. Pair that with a variety of systems having very different problems, it is tough to know where to start.

Even more, selecting the right mechanical seal support barrier fluid isn’t the only consideration that should be on your mind. If your current barrier solution no longer functions optimally to maintain pump reliability, perhaps it’s also time to check in on the seal support system. Let me walk you through this.

Mechanical Seal Support Barrier Types: Where to Start

Fortunately, all seal systems have some similar characteristics. So while gas, liquid, and hot or cold sealing systems have different qualities, there are some common themes when selecting a barrier fluid. The bottom-line: It depends on the current process fluid and operating conditions.

Here are the basics that you need to take into account.

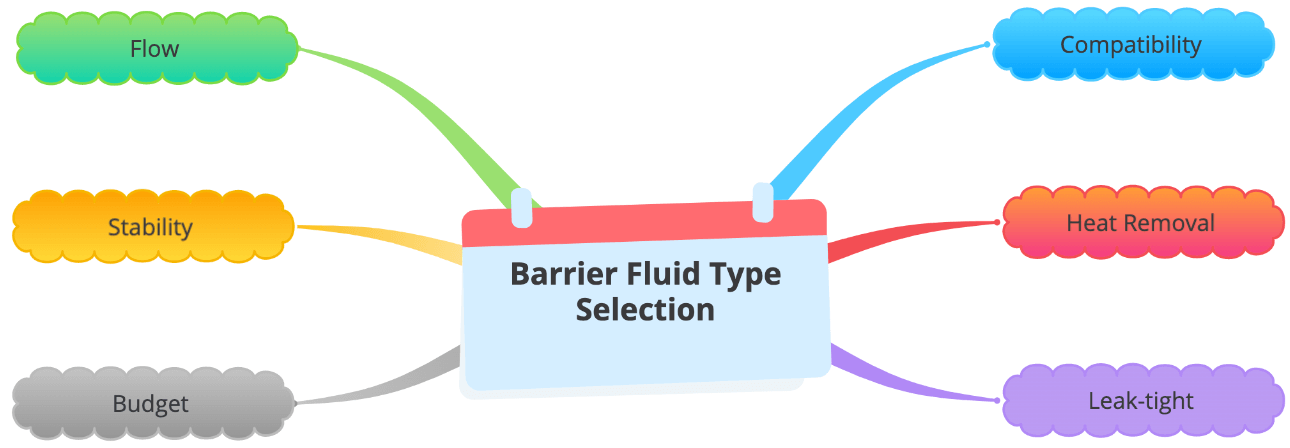

Considerations for Selecting Barrier Fluid Type

1. Compatibility

A barrier fluid must be compatible with the process fluid and conditions it will contact. Incompatibility can result in flashing, coking, or changes in the physical properties of the process fluid.

2. Flow

You need good flow through the mechanical seal to provide enough cooling and lubrication—especially for thicker and more viscous crude oils.

3. Stability

The barrier fluid must not flash, degrade, solidify, or coke during operation. If any of these changes occur, your seal fluid isn’t providing enough lubrication and heat removal.

4. Heat removal

This is especially critical at higher speeds of equipment operation as unwanted heat can build up fast.

| ⇨ It isn’t always the seal fluid, though. Cooling equipment that was adequate a decade ago may not quite be enough anymore. |

5. Leak-tight

The right barrier fluid keeps the hydrocarbon in the pipes and prevents environmental issues. Leakage is simply not an option for a refinery, especially those located in the Bay Area Air Quality Management District.

6. Budget

Availability and cost-effectiveness are always top-of-mind. But too many facilities have continued using a process fluid or water in their seals when there are now many very effective low-cost barrier fluids available. The cheapest solution now may not be the most cost-effective over time for maintaining rotating equipment reliability.

Clearly, a lot of information needs to be gathered before choosing a mechanical seal support barrier type. And that’s just the beginning. It’s often not enough to simply make an improvement in the mechanical barrier seal system. For best results, and to avoid equipment downtime, the change should be supported by an upgraded seal support system as well.

It’s mission-critical to regulate the environment that the mechanical seal operates in to maintain smooth processing. While barrier fluid helps control the contact pressure between seal faces, an appropriate seal support system protects the mechanical seal from receiving process fluid at the wrong pressure and temperature as well. If you’ve noted problems with any pumps, you need to take a look at whether you have the right barrier fluid—and seal support system—for the application.

That’s why you need a seal system vendor with knowledgeable engineers who can help you walk through all of these considerations. Start getting in touch with an expert seal support system vendor who understands local Bay Area process requirements. You’ll want to ensure that they can deliver tested systems quickly when you need them. The vendor also should stand behind their work—even if the assembly sits in the warehouse until there is a turnaround opportunity to install it.

The Best Vendor Choice for Seal Support System Support

Swagelok can help select, design, and assemble a seal support system that goes with the barrier fluid necessary for any Northern California refinery’s specific application. Nearby in the Bay Area, we have a top-tier team of certified engineers ready to help you with all of your seal system selection, design, and assembly needs.

We can fabricate your seal support system to the highest ISO 900 quality standards. When you are ready to install it, Swagelok Northern California will be standing behind our work with a Lifetime Warranty—the best in the industry. From barrier fluid to seal support system selection, let us be your solution.

Let Swagelok Northern California be your first-choice partner for seal troubleshooting, seal selection, design, and fabrication needs. Contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization based in Illinois involved in pneumatic and hydraulic applications where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)