Share this

Corrosion: Pervasive, Problematic, Preventable

by Jeff Hopkins on 9/4/19 9:00 AM

It takes the right materials and the right training to keep corrosion at bay

"Finding a proper materials solution means starting at the source of the problem."

- From Corrosion Types

Just about every metal corrodes under certain circumstances. Even stainless steel tubing is vulnerable to chemical reactions with the fluid inside and the environment outside. If corrosion gets bad enough, fluid can escape and cause a safety hazard. Ignore the problem long enough, and it could lead to a catastrophic system failure.

So it's important to understand the various types of corrosion and how to prevent them. Primarily, the two forms of corrosion that affect stainless steel tubing: pitting and crevice corrosion.

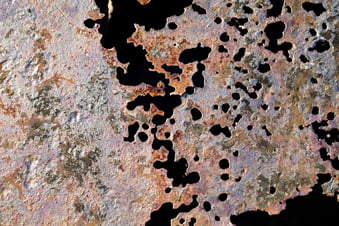

Pitting corrosion

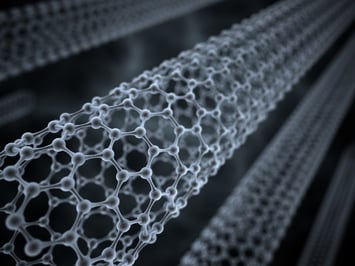

Stainless steels and nickel alloys come with a thin chromium-rich oxide film. When that protective layer breaks down, the exposed metal atoms can give up their electrons easily. This electrochemical reaction creates corrosion in the form of tiny pits.

Stainless steels and nickel alloys come with a thin chromium-rich oxide film. When that protective layer breaks down, the exposed metal atoms can give up their electrons easily. This electrochemical reaction creates corrosion in the form of tiny pits.

Left alone, these tiny pits will grow deeper, eventually even penetrating a tube wall entirely. Pits can also lead to cracks in stressed components.

When monitoring for corrosion, look for reddish brown iron oxide deposits and for pits that may have formed in a metal surface.

Crevice corrosion

Similarly, crevice corrosion starts with the breakdown of the protective oxide film and continues with the formation of shallow pits. Rather than occurring in plain sight, crevice corrosion occurs in crevices - a metal surface in contact with another surface.

Variations on a theme

- Galvanic corrosion occurs when two dissimilar metals come into contact with each other in the presence of an electrolyte, an electrically conducting fluid such as seawater. Galvanic corrosion leads to pitting and material loss of the lesser of the two metals.

- Stress corrosion cracking can be a problem in certain alloys susceptible to chloride-ion induced stress corrosion cracking, such as when they are in salt water environments. The chloride ion interacts chemically with the material where tensile stresses are highest, such as at the tip of a crack. This failure mode is dangerous because it can destroy a component at stress levels below the yield strength of an alloy.

Stop it early

To keep a lid on corrosion, first consider the choice of materials for tubing applications, from the tubing to tube supports and tube clamps.

To keep a lid on corrosion, first consider the choice of materials for tubing applications, from the tubing to tube supports and tube clamps.

Normally, 316 stainless steel tubing works well as long as it is kept clean and temperatures are not excessively high. In hot climates, especially in locations where salt deposits readily form and cannot be washed off, you are more likely to see corrosion. Likewise, 316 stainless steel is more vulnerable in installations where rust from carbon steel structural beams and floors accumulate on stainless steel surfaces.

For these situations, consider using tubing made from superaustenitic or superduplex stainless steel. The higher yield and tensile strength of superduplex stainless steel also make it easier to build systems that must be rated to a high maximum allowed working pressure.

When installing tubing, avoid using tube support strips. The relatively large crevice contact area makes it easier for a corrosive crevice solution to form. Try tubing clamps instead. They minimize clamp-to-tubing contact and make it easier to visually inspect the tubing.

When you are designing a fluid system, minimize crevices and the contact of non-compatible metals susceptible to galvanic corrosion. One way is to avoid placing tubing directly against walls or against each other.

Keep an eye out

Regular inspections, and knowing what to look for, are as important as good design. Swagelok's classroom instruction and hands-on training can be invaluable for operators and technicians. Even if you have a corrosion expert, it's smart to build a basic understanding of corrosion - what it looks like, where it occurs, and for what reasons - among those who work with tubing systems every day.

Regular inspections, and knowing what to look for, are as important as good design. Swagelok's classroom instruction and hands-on training can be invaluable for operators and technicians. Even if you have a corrosion expert, it's smart to build a basic understanding of corrosion - what it looks like, where it occurs, and for what reasons - among those who work with tubing systems every day.

Just ask

Swagelok Northern California has a great deal of exposure to all aspects of fluid system design and engineering. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)