Share this

Custom Gas Distribution System Design and Fabrication

by Malik Durojaiye on 8/19/21 9:00 AM

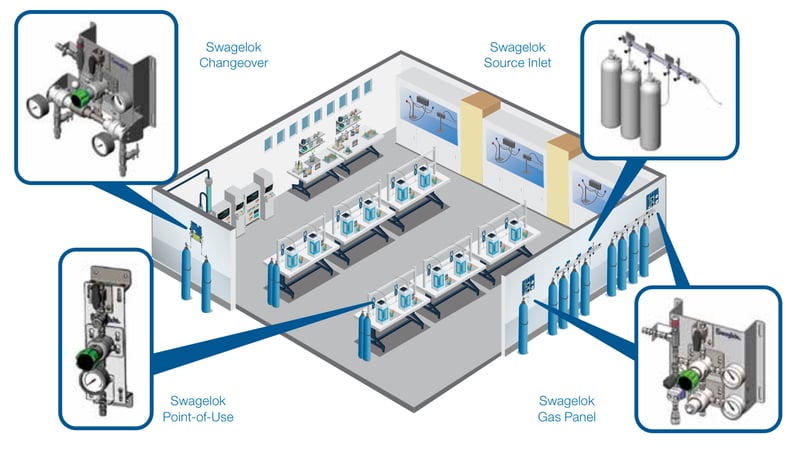

Fluid handling facilities depend on gas distribution system design to safely and efficiently deliver gases from a high-pressure source to various points of use at the required pressure and flow rate. The gases involved are under pressure and can be toxic, corrosive, or flammable, so safe and efficient operation requires careful design decisions. Proper gas distribution system design can prevent leaks, downtime, and safety hazards—protecting operators and keeping your system running efficiently.

Gas distribution systems typically have four subsystems: the source inlet, gas panel, changeover, and point-of-use. Here, we’ll look at each of these subsystems and go over some general design recommendations to maximize safety and efficiency.

Safety and Efficiency Design Considerations

Gas distribution systems may involve hazardous gases. To prevent harm to operators, equipment, and the environment, the gas distribution system design must account for these potential hazards and mitigate the risks as much as possible.

Here are a few things to keep in mind for any gas distribution system design:

- Reduce potential leak points by minimizing the number of connections.

- Make maintenance and troubleshooting easier by locating all components and panels where they’re easy to access.

- Arrange components and clearly label them to prevent errors.

Special Considerations for Oxygen Systems

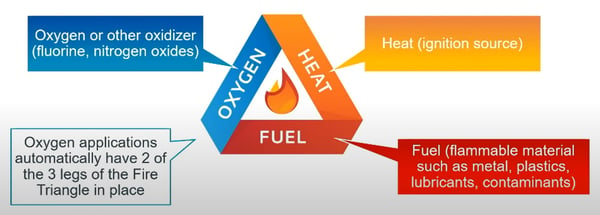

Oxygen systems can be a significant fire hazard. Materials that may be safe in atmospheric oxygen levels can ignite in an oxygen-enriched environment.

The “fire triangle” above shows the three elements needed to ignite a fire: oxygen, fuel, and heat. Usually, fires in the atmosphere can be prevented by removing or limiting those elements, but oxygen and fuel inevitably exist in an oxygen handling system. Careful gas distribution system design decisions can minimize the risk of fires by eliminating sources of heat or ignition energy. Some ways to do this include:

- Avoid using stainless steel piping or tubing. Oxygen systems must be made of special materials like brass or ceramic.

- Avoid using any type of flammable oil or grease in the system.

- Use only smooth-bore tubing.

Swagelok Source Inlet (SSI)

The source inlet connection is the first stage of a gas distribution system, which connects the high-pressure gas source (one or multiple gas cylinders or bottles) to the rest of the system. For a single-cylinder, the source inlet may simply be a hose with a cylinder connector. When there are multiple cylinders or bottles, the source inlet can be a more complex system of hoses and valves that deliver the gas to the primary gas pressure control or automatic changeover system.

Like the rest of the gas distribution system design, the source inlet is based on the application. Some options include:

- Isolation valves

- Vent or purge for individual lines

- Bottle identification tags

Swagelok Gas Panel (SGP)

The gas panel is the primary gas pressure control. It must reduce gas pressure while maintaining the required system flow. It accomplishes this with either a one- or two-stage pressure regulator arrangement. The exact gas panel design specifications depend on the gas being handled and individual process requirements.

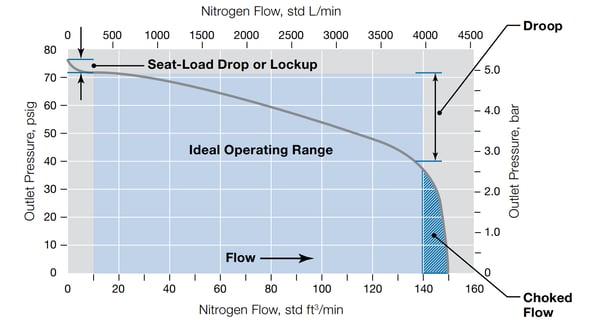

The pressure regulator is the heart of the gas distribution system, so it’s critical to select the right one. The regulator should operate along the flattest part of the flow curve.

The example above illustrates the three parts of a flow curve:

- The ideal operating range, a relatively flat part in the middle

- The seat-load drop or lockup, where there is an initial steep pressure drop as flow begins

- The choked-flow area, where the pressure regulator is completely open and no longer regulating pressure

To prevent failures, the pressure regulator should have a filter upstream to remove solid particles and protect the regulator. The size and material of the filter element and its housing depend on the gas composition, solids content, pressure, flow, and other system characteristics.

Swagelok Changeover (SCO)

An automatic changeover system seamlessly switches from one gas source to another when it reaches a set changeover pressure. It provides primary pressure control without ever interrupting the gas supply, letting the system operate continuously at a constant pressure. Eliminating manual changeovers also saves time and eliminates human error.

Changeovers can be semi- or fully automated. There are also additional safety options available for hazardous gas or oxygen systems.

Swagelok Point-of-Use (SPU)

Point-of-use systems are usually the least complex part of gas distribution system design. They provide the last stage of pressure control before the gas is used. A point-of-use station typically contains a pressure regulator, pressure gauge, and isolation valve to let operators precisely adjust the pressure for the application needs.

A point-of-use system should provide standard, consistent operation and be convenient and safe for the operator. Compact design and custom mounting options can help maximize space and make the system as easy and safe to use as possible.

| After watching the latest webinar, check out the Q&A that took place with Matt Dixon. |

How We Can Help with Your Gas Distribution System Design

Whether you’re installing a new gas distribution system or upgrading an existing one, Swagelok can help. Our Field Engineers can evaluate existing systems, recommend the best components, subsystem design, and gas panel layout for new systems, and develop equipment management programs based on your facility’s needs. We provide standardized, modular systems and options, customized to your operation.

To find out more about how Swagelok Northern California can help with your gas distribution system design needs, contact our team today by calling 510-933-6200.

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)