Share this

Why a Gas Sampling Bomb for Hydrogen Should Come From a Local Vendor

by Morgan Zealear on 7/27/21 1:30 PM

With hydrogen becoming an increasingly important source of clean energy, refineries that are retooling to increase hydrogen production, as well as start-up producers entering the market, will have an increased need for hydrogen sampling. In many instances, spot sampling occurs when a volume of hydrogen is taken at high pressure using gas sampling bombs and then transported to a laboratory for analysis. Considering the frequency of samples, an adequate supply of gas sampling bombs is important in keeping the production process running. A shortage of gas sampling bombs can delay sampling. If an upstream process is problematic, it can result in the production of a substandard product. A sampling delay or contaminated sample can lead to dissatisfied customers and possible sanctions.

| Learn about hydrogen’s effect on different materials and problems with embrittlement through this Materials Science For Hydrogen Service Webinar that explains the fundamentals from a materials science perspective. |

Process and quality control engineers can rest easier when they know that there’s an adequate supply of clean gas sampling bombs on hand, and in the event there’s a need for additional gas bombs, they can be obtained quickly. Working with a local grab sampling system vendor is the best way to achieve this level of assurance. A local vendor is not only convenient, but they can also provide technical recommendations that help ensure consistent representative hydrogen gas samples. But first, let’s discuss the various options when configuring gas sampling bombs for hydrogen.

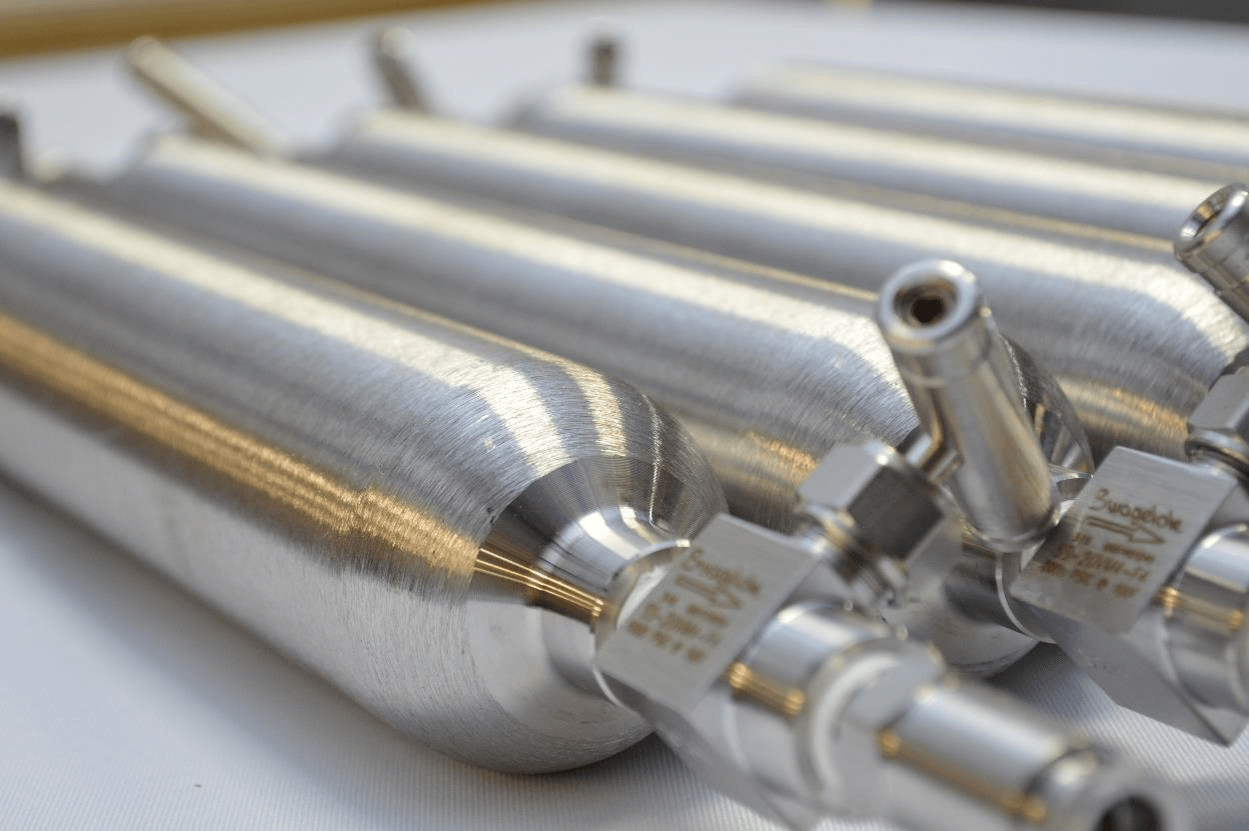

Gas Sampling Bombs for Hydrogen: Multiple Options

Hydrogen is a small-molecule gas that easily escapes through microscopic openings and diffuses into materials designed to contain it. In dealing with gas bomb sampling for hydrogen, a local vendor can provide value, well beyond simply supplying gas sampling bombs. Field Engineers, experienced in consulting on a wide range of gas sampling systems, can conduct a plant visit, assess the hydrogen sampling requirements, and recommend the options best suited for the sampling process. Options may include:

- Sizes: gas sampling bombs are available in 150, 300, 400, 500, and 1,000 cm3 volumes

- Materials: seamless tubing produces consistent wall thickness and can be 304L or 316L stainless, 400 alloy, or alloy C-276

- Coatings: electropolishing, PTFE coating, or SilcoNert® can be used to reduce sample gas absorption and adsorption into the sample bomb’s surface, and make it easier to purge sampling bombs of residual fluids

- Handles: a convenient and safe way to transport gas sampling bombs; available for 300 cm3 and larger bombs

- Markings: permanently marked with department, process, location, or serial numbers; as a precaution, gas sampling bombs are not marked with the intended contents

- Safety: Outage tubes provide a vapor space, allowing pressurized hydrogen gas to expand when the ambient temperature increases. End caps protect gas sampling bomb valves from damage whenever the bomb is not attached to the sampling station.

- Levels of DOT Certification: various levels of DOT certification including DOT-3A 5000, DOT-3E 1800, DOT-3A 1800, DOT-SP7458 1000, DOT-4B 500.

With the guidance of an experienced Field Engineer, you’ll obtain gas sampling bombs for hydrogen that are ideally configured with options that enhance safety and sample consistency for each of your sampling processes.

Options to Improve the Hydrogen Sampling Efficiency and Quality

An on-site visit by a Field Engineer can also identify opportunities to improve the efficiency of the hydrogen sampling process. When you’re capturing hundreds to thousands of samples, even the smallest improvements in sampling efficiency can add up to long-term cost savings. Two options to consider are quick connections and a purge bypass tube.

capturing hundreds to thousands of samples, even the smallest improvements in sampling efficiency can add up to long-term cost savings. Two options to consider are quick connections and a purge bypass tube.

Stainless steel quick-connects facilitate safe and easy attachment and detachment of gas sampling bombs from sampling stations. Quick-connects can easily handle the high-pressure hydrogen sampling and offer unrestricted flow for gas transfers. Quick-connects can be keyed to prevent accidental intermixing of different lines in multi-pressure or multi-fluid systems.

Purging helps ensure the capture of representative, contamination-free hydrogen samples.

A purge bypass tube allows inert gas such as nitrogen to circulate through the sampling station connections to remove residual sampling gas before or after taking the hydrogen sample. The inert gas and any residual gases are then purged to vent.

Swagelok: Your Local, Experienced Vendor

Swagelok offers a wide range of system components for hydrogen applications in the energy industry, and infrastructure for hydrogen production, transport, and storage. Swagelok products are well suited for hydrogen systems due to their leak-tight components, material compatibility, and high-pressure resistance.

With a presence in Northern California, we can provide on-site consulting to assess your gas sampling bomb requirements. Our extensive inventory of high-quality components and certified technicians with years of experience fabricating sampling systems allows us to quickly deliver gas sampling bombs for hydrogen as well as complete grab sampling systems tailored to your facility.

To find out more about how Swagelok Northern California can meet your requirements for gas sampling bombs for hydrogen by providing expert consultation, products, and assembly services, contact our team today by calling 510-933-6200.

Morgan Zealear | Product Engineer – Assembly Services

Morgan Zealear | Product Engineer – Assembly Services

Morgan holds a B.S. in Mechanical Engineering from the University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration, and Mechanical Efficiency Program Specification (API 682). He is also well-versed in B31.3 Process Piping Code. Before joining Swagelok Northern California, he was a Manufacturing Engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)