Share this

System Design for Gases Used in Semiconductor Manufacturing

by Morgan Zealear on 3/21/23 9:00 AM

![]()

As the semiconductor market grows, the standards for purity and precision are becoming more and more strict. One of the defining factors for quality semiconductor manufacturing is the gases used in the process. These gases have many roles to play during manufacturing, including:

- Precision process control

- Contamination prevention

- Metallurgical property enhancement

To effectively fulfill these roles, the gas supply and distribution system must be highly efficient. The design of the handling system for gasses used in semiconductor manufacturing must be backed by robust components and a custom assembly to account for the reliable and high-quality production of semiconductors.

Gases Used In Semiconductor Manufacturing

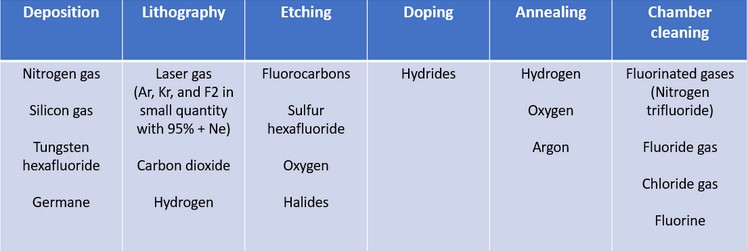

The process of manufacturing semiconductors requires using different gases at different phases, as represented in the table below.

While common gases such as nitrogen, hydrogen, argon, and helium can be used in their pure form, some processes may require a specialized mixture. Silane or siloxane, hexafluoride, halides, and hydrocarbons are a few specialty gases used in semiconductor manufacturing. Among these gases, many of them can be hazardous or highly reactive, contributing to the challenge of component selection and design of the gas system.

Here are a few examples:

- Hydrogen and helium leak easily from piping and fitting systems due to their low atomic size and weight.

- Silane is highly flammable and can ignite spontaneously in the air (pyrophoric).

- Nitrogen difluoride used during deposition, etching, and chamber cleaning phases, can act as a potent greenhouse gas when it leaks into the environment.

- Hydrogen fluoride, the etching gas, can be highly corrosive to metal piping.

- Trimethylgallium and ammonia can be difficult to handle—a small fluctuation in their temperature and pressure requirement can affect the deposition process.

Controlling the process conditions to minimize the negative effects of these gases must be the utmost priority during the system’s design. And during the build, it is just as crucial to use the highest quality components like Swageloks Diaphragm Valves.

Handling The System Design Challenges

Semiconductor-grade gases are high purity in most cases and provide inert conditions or enhanced reactions at different phases of the fabrication process (such as the etching and deposition gases). Leaks or contamination of such gases can have a negative effect. Therefore, it is vital for the system components used to be leak-tight and corrosion-resistant with smooth finishing (electropolished) to ensure there is no potential for contamination—and extreme cleanliness can be maintained.

Moreover, some of these gases may be heated or cooled to achieve the desired process condition. Well-insulated components can ensure temperature control which is essential for the efficient performance of the final product.

From the source inlet to the point-of-use, Swagelok’s wide range of components supports ultra-high purity, temperature, pressure, and flow rate control required in semiconductor cleanrooms and vacuum chambers.

Design System With Quality Components In Semiconductor Fabs

The role of quality components and design optimization is critical for precision control and the safe fabrication of semiconductors. The components in use need to be strong and free of leaks to conform to the varying process conditions required at different phases of fabrication. Swagelok’s high-quality valves, fittings, regulators, tubings, and seal supports offer the following features:

- Ultra-high purity

- Leak-free sealing

- Temperature control insulation

- Pressure control

- Corrosion-resistance

- Electropolished finish

In addition, as a local fluid system expert for your northern California facility, Swagelok can also help you evaluate and optimize your existing gas system to enhance its reliability. With the best-fit and high-quality components, your semiconductor manufacturing process is sure to be efficient.

To find out more about how Swagelok Northern California can help you handle the gasses used in semiconductor manufacturing, contact our team today by calling 510-933-6200.

About Morgan Zealear | Product Engineer, Assembly Services

About Morgan Zealear | Product Engineer, Assembly Services

Morgan holds a Bachelor of Science in Mechanical Engineering from University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration and Mechanical Efficiency Program Specification (API 682), and he is well versed in B31.3 Process Piping Code. Before joining Swagelok Northern, he was a manufacturing engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)