Share this

Give Your Tubing All The Support It Deserves

by Jeff Hopkins on 2/6/20 8:45 AM

A well-designed and supported system fends off shock and vibration

"Tubing may be inappropriately used as a support for other objects,

which may lead to damaging the tube."

- From Swagelok Tube Fitter's Manual

As light and as flexible as tubing may be, it still needs adequate support so that your fluid system will stay leak-free. And while you may know that intuitively, you still might not be sure how much support is enough, or where it is needed most. That's OK. Swagelok Northern California has the information you need to do the job right.

When and where

When does tubing need some extra support? Any time you have long runs of tubing you run the risk of sagging. The heavier the fluid in the system, the more support the tubing needs. The Swagelok Tube Fitters Manual has tables that show the proper spacing of supports for various diameters of tubing in various types of service.

For instance, half-inch tubing should have clamps every five feet. For one-inch tubing, you can space the clamps seven feet apart.

It's also vital to take impulse and vibration into account. They make tubing move more than it should, so you want to install supports that limit movement.

Supports are also needed around elbows, tees, bends, and heavy in-line objects such as valves. All tubes should be clamped on both sides of a bend, as close to the bend radius as possible.

Options

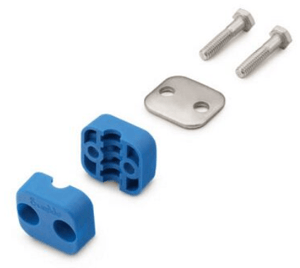

Bolted plastic clamp supports offer versatility for mounting tubing and pipe. In addition to absorbing shock and vibration, they resist many chemicals and corrosives.

Bolted plastic clamp supports offer versatility for mounting tubing and pipe. In addition to absorbing shock and vibration, they resist many chemicals and corrosives.

They resist ultraviolet light too. We have them in three support kit configurations: single, twin, and single stacking. With the single stacking kit you can stack up to three single bolted plastic clamp supports. The top support uses a cover plate. The lower supports use a lock plate.

We also offer them in three mounting configurations: weld plate, mounting rail and rail nuts, and strut nuts. For the weld plate option, the nuts are welded to the weld plate not press-fitted. With the mounting rail and rail nuts, you can add or remove nuts as needed anywhere along the rail span. Neoprene caps hold the nuts and support body in place. Strut nuts are for use on 1 5/8 inch strut rail mounting systems.

We also offer cushioned clamp tube supports for channel mounting, and polypropylene tube support strips for organizing multiple tubing or hose runs.

Or you might only need a simple P clamp. It's an economical way to support tube or hose runs in a variety of sizes, and all you need is a single screw or bolt to attach it to a wall or an equipment frame.

By design

Strong supports are not a substitute for good design. Tubing is not meant to support the weight of valves, regulators and other components. Those components should be mounted. It's also important to avoid placing tubing where it would make a tempting handhold.

Just ask

Swagelok Northern California has a great deal of exposure to all aspects of fluid system design and engineering and with the right supports in the right places, your fluid system will be even more reliable and easier to maintain.. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

- Swagelok Tube Fitter's Manual (download page)

- Swagelok Tubing and Tube Accessories (product page)

- Hose vs Tubing: Which one is best for an application? (blog)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)