Share this

How to Extend a Mechanical Seal Lifespan When Petrochem Plant Budgets are Lean

by Paul Lesnau on 6/30/20 8:45 AM

The oversupply of oil has upset global petroleum markets and forced unexpected cutbacks in production, delayed infrastructure investments, and reduced budgets at every level of petroleum operations. Yet, within these constraints, in California, you still must continue to maintain critical assets in good working order.

With the Bay Area experiencing reduced operations, even a single pump failure can have a detrimental and costly effect on productivity. Mechanical seals account for more than a third of pump failures. So every effort to extend mechanical seal lifespan reduces unplanned downtime and lowers operational costs.

But how can reliability engineers like you extend mechanical seal lifespan to prevent leakage and other problems that impede production? To answer that question, in the following recommendations I assume you’ve installed the correct mechanical seals in pumps. I focus only on factors that can cost-effectively ensure optimum pump seal performance.

Mechanical Seal Reliability Process Condition Changes: Cause and Effect—And Solutions

In Bay Area petroleum plants that have been operating for decades, many pumps, mechanical seals, and support systems were installed with the intent of meeting process requirements that have since changed. In some cases, changes can negatively impact mechanical seal integrity. When operating conditions change, you may see some resulting effects. Take a look at the range of consequences.

| CAUSE | EFFECT |

| Increase in fluid temperature | Reduces the life of a seal’s elastomeric components, changes seal face dimensions causing leakage, vaporizes process fluid between seal faces, increases corrosion within the pump casing |

| Increased contaminants or particulates in process fluids | Becomes embedded in seal faces causing increased wear, especially on hard/ soft seal face material pairings, leading to leakage |

| Pump is no longer operating within its recommended BEP flow | Recirculation and cavitation causes vibration transmitted from impeller to pump shaft to mechanical seal with potential loss of fluid film, higher friction, and degradation of seal faces |

| Pump suction pressure has increased | Moves the pump off the BEP, creating a larger thrust force on the pump impeller and bearings, and consequently increases friction on the process side seal face |

| Pumps have unexpectedly run dry as a result of improper shutdown or sudden cessation of fluids at suction | Rapidly increasing heat build-up on faces quickly degrades seals leading to extensive leakage |

SOLUTION: If processes have changed since the original installation of pumps and seals, ensure that seal support systems have been upgraded or modified to provide the proper seal chamber environment. This includes:

- Filters or cyclone separators to remove particulates from process fluids

- Buffer gas or barrier fluids suited to the temperatures and pressures of fluids currently being processed

- Added cooling capacity via greater capacity coils in seal pots or upgrading to a heat exchanger

- Heavier-wall tubing for extra rigidity in high-vibration environments or areas prone to frequent contact with operations personnel or equipment

- Upgrading to a seal support system that more closely meets the current process requirements. For example, replacing API Plan 53A Barrier Fluid Seal Pot Pressurized by Nitrogen with API Plan 53B Barrier Fluid Pressurized by Bladder Accumulator to permit operation at higher pressures.

More Factors Affecting Mechanical Seal Support System Lifespan

Other factors that may shorten a mechanical seal support system lifespan are mechanical changes in pump performance that might be attributed to improper installation, poor maintenance practices, or asset degradation. Here are two common mechanical causes:

| CAUSE | EFFECT |

| Pump vibration | Vibration may be caused by damage to an impeller, worn out thrust or radial bearings, or misalignment of drive motor, coupling, or pump shaft. Each of these can cause seal face deflections resulting in leakage |

| Vibrations that affect tubing and connections | In seal support systems located in close proximity to pumps, vibrations may affect tubing and connections, causing barrier, buffer, or flush leakage that reduces seal support effectiveness |

SOLUTION: Ensure pumps and any supporting infrastructure—piping, supports, location of seal support systems—are properly installed and maintained to minimize the chance of mechanical factors compromising seal reliability.

Simple Cost-Effective Measures To Improve Mechanical Seal Efficiency and Lifespan

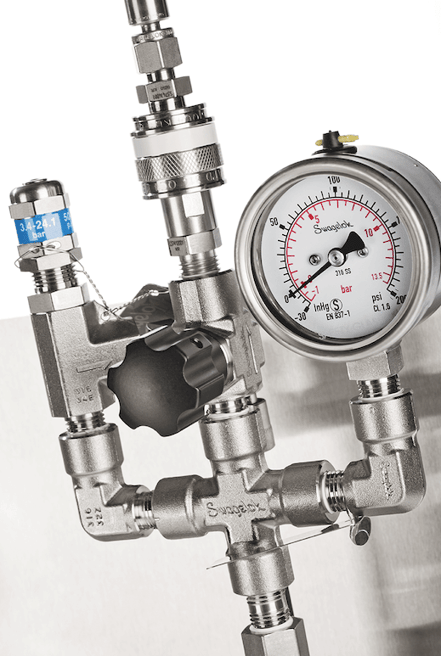

With the range of the factors that affect mechanical seal lifespan, you can take further cost-effective measures to extend the efficiency of existing seal support systems with component improvements such as:- Temperature and pressure gauges to monitor the conditions of seal chambers and support systems

- High-point vents to safely release entrapped air that impedes cooling

- Low point drains to purge buffer, barrier, or flush fluids quickly and safely for easier maintenance

The notion of cost-effectiveness balances expenses against results. Some measures involve labor-only—just a matter of timely inspections and proactive corrections of potential problems. Other instances incur minor expenses, like replacing or upgrading components to improve the efficiency of a seal support system. Some issues justify greater expense such as completely replacing inefficient seal support systems with a new system.

An Opportune Time To Evaluate Your Mechanical Seal Needs

With reduced operations at the plant, it may be an opportune time to evaluate critical pump operations, identify issues, and initiate cost-effective plans to ensure pumps and seal support systems are operating as efficiently as possible.

Swagelok, with locations in Fremont and Concord, has decades of experience helping petroleum plants in the Bay Area with seal support system requirements. We’re available to consult with you on-site to assess your needs, provide guidance on best maintenance practices for seal support systems, recommend appropriate component upgrades, or help you select the right seal support system to replace an outdated system.

Our local presence enables rapid design, assembly, testing, and delivery of new seal support systems, quick delivery of components and spares, and always-available technical support by phone. We welcome the opportunity to work with you in finding cost-efficient solutions in times of lean budgets.

To learn how Swagelok Northern California, can help you extend mechanical seal lifespans in lean budgetary times by providing expert consultation and Assembly Services, contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization based in Illinois involved in pneumatic and hydraulic applications where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)