Share this

More On Threads: Pressure, Tolerance And Corrosion

by Jeff Hopkins on 6/26/19 9:00 AM

A few extra thoughts on getting a good seal and making sure it stays that way

"Every male thread Swagelok produces is installed with a plastic protective cap for shipping. Protective covers keep threads from being accidentally dented or otherwise marred. A dent in a male pipe thread is a time bomb."

- From Nice Threads! Make Sure You Keep Them That Way

While a good seal is always vital when joining pipe threads, some seals are more straightforward than others. Today let's look at some circumstances when life gets a little more complex.

Plastic on Metal

Assembling a metal fitting into a plastic body part is very common when putting a high-flow filter into a cooling water system.

Assembling a metal fitting into a plastic body part is very common when putting a high-flow filter into a cooling water system.

Female tapered threads in plastic typically have significant sealing issues. Tighten the fitting too much and the plastic body will split ruining

the filter. Tighten too little and it will never seal. Female tapered threads in plastic are typically a looser fit compared to metal, because of this it helps to go thick by using a combination of PTFE tape and SWAK to fill the gaps.

Parallel Threads and NPT O-seal

Parallel threads are gaining popularity, and for good reason. The main advantage is that they seal against an O-ring and with little assembly torque.

Parallel threads are gaining popularity, and for good reason. The main advantage is that they seal against an O-ring and with little assembly torque.

The main disadvantage is that there are still a large number of devices on the market that simply do not have parallel thread fittings available.

Parallel threads are made in three main standards:

SAE (Society of Automotive Engineers), BSPP (British Standard Parallel Pipe), and Metric. Both SAE and Metric threads follow fastener thread standards, so if you have a tap set you can likely cut several SAE threads. BSPP is used less often but is still quite common. BSPP threads are most commonly identified with a “G” prefix to the fitting size.

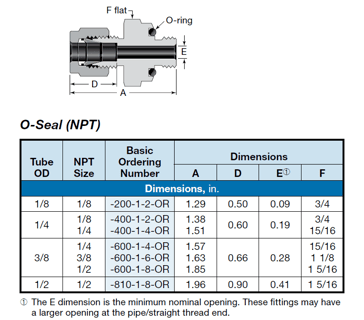

To provide a compromise for NPT availability versus O-ring seals, Swagelok offers NPT O-seal adapters. A special parallel thread adapter with a captured O-ring seal allows for installation into female NPT fittings.

Sealing Pressure

A very common question during customer fluid systems training is about the pressure rating of various thread sealing materials. For the most part, the rated pressure of a pipe joint is determined by the rating of the pipe itself or the components used. Swagelok PTFE Tape Pipe Thread Sealant does not have a rated maximum pressure. SWAK and PTFE-free liquid sealant are both limited to 10,000 PSIG. That being said, if you are designing a system to go beyond 10K PSIG it’s better to avoid threaded fittings altogether and use high-pressure tube fittings.

Assembly Tolerance

During the design phase an extremely common error is not allowing for enough space between components with tapered thread fittings. Both NPT and BSPT standard threads are incredibly unpredictable when designing the final position of a fitting in a joint. The distance can vary based on the materials used, the amount of thread sealant applied, and the amount of torque used to assemble the connection. When you are tight for space and trying to get a lot of components closely packed together consider this variability in total length with tapered fittings so you don’t run out of space during assembly.

Corrosion and Chemical Compatibility

Far too often, we get calls about severe corrosion causing leaks in a fluid system. Leaks are bad, gushing leaks are worse, and gushing leaks that shut down a factory can cost hundreds of thousands of dollars in lost time. Sometimes they even result in damage or human injury.

A commonly overlooked cause is galvanic corrosion, which happens when two dissimilar metals are joined together in a fluid system with a conductive fluid media in the line. When the metals have a significant enough difference between them in voltage potential, such as aluminum and copper, the alloy farthest from zero potential will begin to ionically decompose. Pits will form in the metal with higher potential, and deposits will form on the metal with lower potential (typically). If you look online for a “galvanic series chart” you should find a number of graphs showing the difference in potentials of various metals. Before designing a joint in a system that is made of different metals, review a galvanic chart and save yourself in the long run.

Another very important check when designing a fluid system is chemical compatibility of media. Untreated steel pipes and water are a bad combination. If you download a copy of our Tube Fitter’s Manual, you’ll find a listing of chemical compatibility in the appendix. A quick reference check can save you big time in the long run.

Ask the Experts

Every day Swagelok Northern California helps our customers design, build and maintain fluid systems. We employ a team of highly trained, certified fluid system assemblers for building everything from simple pressure regulator assemblies to full chemical mixing systems, gas boxes, and liquid cooling systems. When you want expert advice talk to the experts, and at Swagelok, we are the fluid system experts.

More like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)