Share this

Rotating Equipment Failure Types—And How to Reduce Unplanned Downtime in Your Plant

by Paul Lesnau on 3/19/20 8:45 AM

In a recent conversation with reliability engineers at a Concord, CA petrochem plant, they voiced the frustrations of unplanned downtime. Whether it’s five minutes or five days, their time goes toward minimizing these interruptions. Rotating equipment failures, especially, can bring operations to a standstill. That’s why extending the mean time before failure (MTBF) for rotating equipment associated with pumps from three years to five years, like other refineries in the Bay Area, was top of their list.

Up-front risk assessment and definitive plans to mitigate specific risks associated with different types of rotating equipment failures will boost overall equipment effectiveness (OEE) throughout the plant. With proper planning, maintenance, and support systems, reliability engineers can create an environment that extends MTBF to significantly reduce unplanned downtime. It all starts with ensuring you have the right components for the service requirements—a task that doesn’t have to be easier said than done.

Four Common Rotating Equipment Failure Types In Pumps

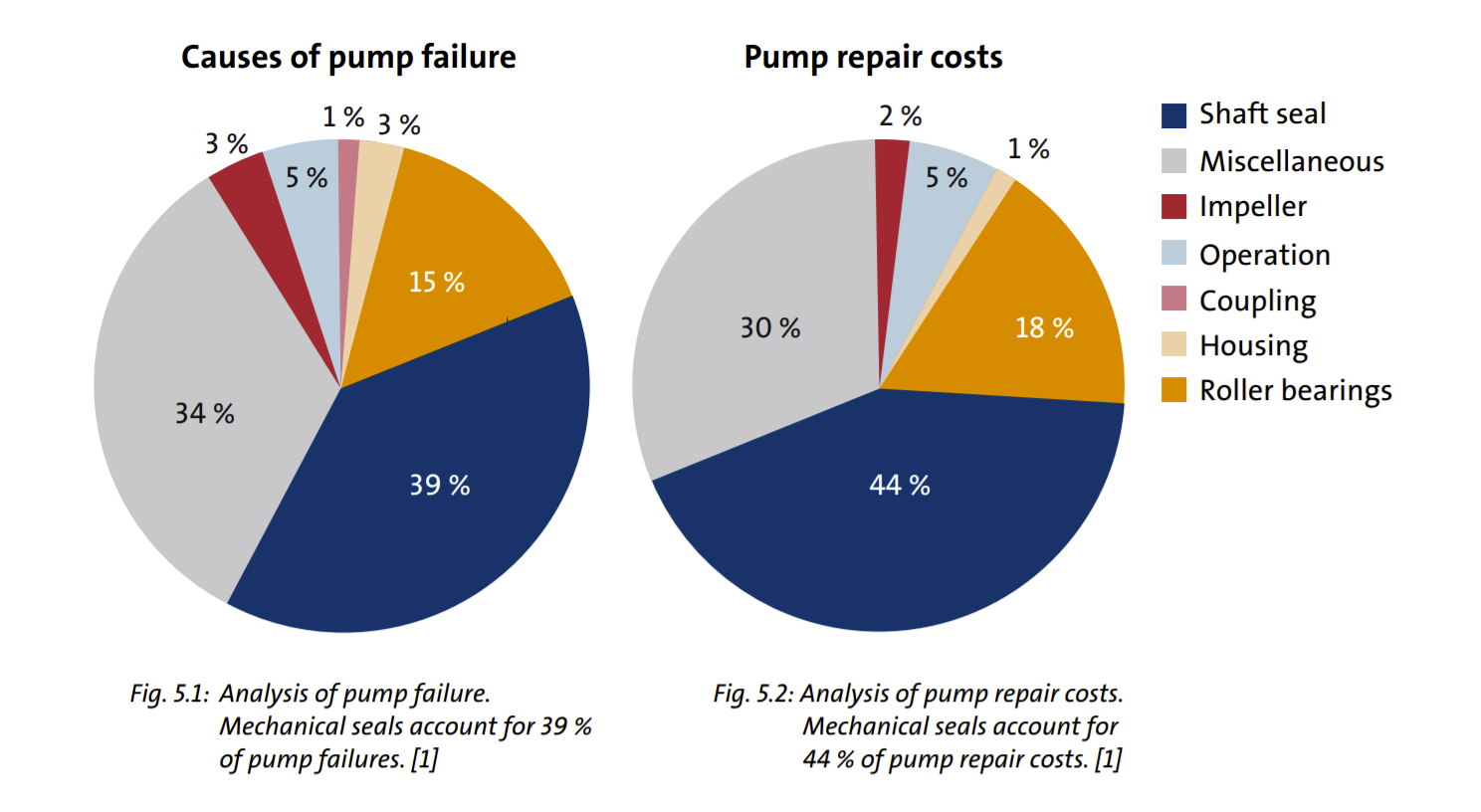

Mechanical seal failure is the most common reason for pump failures (Grundfos).

Maintaining the optimum operating environment for mechanical seals is challenging, considering the complexity of the seal designs and the varying operational demands placed on pumps. Most failures that you can expect to encounter are related to component degradation. Below, I’ll walk you through the frequent rotating equipment failure types, their causes, and how to help mitigate them with quality seal support systems.

#1 Pump Seal Dries/ Burns Up

Indication of failure: Burnt elastomeric parts, immediate leakage.

Causes: The pump running dry due to operator error or miscommunication from an upstream process results in the absence of pumped medium, creating heat-building friction. Within minutes seals with hard seal faces can reach several hundred degrees and disintegrate.

| ⇨ Solution: Mechanical seal support systems providing compatible fluids and proper flow through seal chambers may extend the life of pump seals. |

#2 Leakage

Indication of failure: Visual or odor detection, though leakage patterns vary. Rate of leakage can change during the pumping cycle as well.

Causes: Improper seal installation, reduced spring load, one or both seal faces not flat, vaporization across seal faces, and elastomer damage or hardening are typical causes of leakage.

| ⇨ Solution: Ensure proper pressure, flow, and venting of fluids through the seal chamber to prevent leakage with a quality seal support system. |

#3 Lubrication

Indication of failure: Constant or random loud noises, often accompanied by vibration, from shaft seals with hard material seal faces.

Causes: Very low viscosity of the pumped medium provides insufficient lubrication. Frictional heat dissipates across the seal face causing small, radial, seal face cracks that increase friction. We don’t tend to see this very often in the Bay area because sour crude is very viscous but it’s worth noting as a potential problem area.

| ⇨ Solution: Remove heat from the seal chamber via flush fluid using coolers or heat exchangers. Deliver clean flush fluid to the seal chamber when the process fluid is unsuitable for use as the flush fluid. |

#4 Contamination

Indication of failure: Leaking shaft seal, mechanical shaft seal hang-up, hesitant pump starts when seal rings are sticking together.

Causes: Metal-on-metal, caused by impeller or shaft misalignment, within the pump creates particulates. Pumped medium contains small suspended insoluble particles that build up on seal faces. Corrosion can result from high-sulfur content of sour crude, which is common in Bay Area refineries. Precipitation or sedimentation accumulate in/ near the sealing gap, springs, bellows, seal-drivers, or O-rings.

| ⇨ Solution: Eliminate particulates from the flush stream by way of filters or cyclone separators in a seal support system. Filter or flush ports to run reverse flows to clean seals. |

The most effective means of reducing unplanned downtime caused by these four rotating equipment failures types is the use of quality mechanical seal support systems. Properly assembled and installed seal support systems reduce friction, prevent leakage, extend pump life, and improve the overall operational efficiency and safety of rotating equipment.

Reduce Unplanned Downtime With Mechanical Seal Support Systems

Well-designed seal support systems employ a selection of easily accessible components to monitor performance and minimize unplanned maintenance activities. You should look for mechanical seal support systems in a range of API 682 plan assemblies or support kits designed to provide the optimum operating environment. These components should include:

- Pressure and temperature gauges to indicate seal chamber and seal support system conditions

- Isolation valves and bypass loops to obviate the need for complete shutdown

- High-point vents to easily bleed out any entrapped air in the system

- Low point drains to quickly and safely purge buffer, barrier, or flush fluids

- Easily-accessible filters located for easy replacement

- Block-and-bleed valves (recommended by API) for safe calibration or removal of components for servicing

A wide range of API 682 plans and numerous options to configure a plan to the specific pump and processing needs enable petroleum plants to mitigate some of the most common rotating equipment failure types and boost uptime of refining equipment.

The Best Solution for Rotating Equipment Failures

You can gain control over unplanned downtime caused by rotating equipment failures with Swagelok Northern California’s seal plan kits and assemblies as well as local comprehensive design and support services. We can even provide the added advantage of standardization and scaling by building the systems for you. You’ll benefit from our decades of experience working with Bay Area petrochemical processing plants to improve pump efficiency, reduce unplanned downtime, and simplify maintenance of these critical assets.

To find out how Swagelok Northern California can help solve rotating equipment challenges and reduce unplanned downtime, contact our team or call 510-933-6200!

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization based in Illinois involved in pneumatic and hydraulic applications where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)