Share this

Thanks to Swagelok and API, Seals Can Stay Healthier

by Jeff Hopkins on 12/14/18 8:45 PM

With our mechanical seal support systems you'll extend useful life and keep costs down

"Pump shaft seals cost thousands of dollars, and a refinery might have 1,000 of them or more. Do the math, and you can see why it's important to keep the seals in good condition."

Seals, Seals, Seals

Pump shaft seals cost thousands of dollars, and a refinery might have 1,000 of them or more. Do the math, and you can see why it's important to keep the seals in good condition. Then consider other mechanical seals you may have in mixers or compressors, whether they are driven by electric, steam, hydraulic, or compressed gas motors.

If mechanical seals are your responsibility, you probably have already run a process hazard analysis, either formally or in your head: What happens if equipment fails? What are the consequences of a leak, spill, fire or explosion? What are the likely methods of failure? (If something leaks on a hot motor, for instance, it might start a fire.)

An ounce of prevention

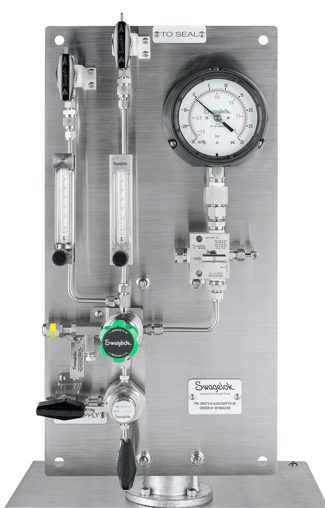

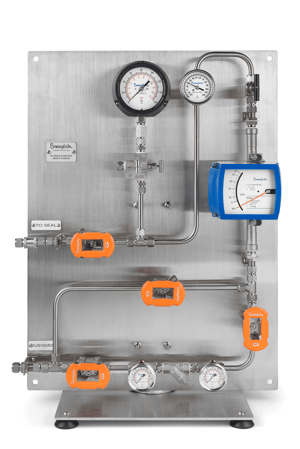

Keeping everything running smoothly is a hard job, involving lots of in-the-field engineering. We want to help make it easier with Swagelok Northern California's mechanical seal support systems. They are fully assembled or kitted to meet your specific needs, and we can configure them for process side, atmospheric side, and between seal plans. These systems can offer a reliable and high performance solution to your mechanical seal operations.

Swagelok Mechanical Seal Support Systems

According to the plan

The American Petroleum Institute has a set of recommendations that applies to mechanical seals for rotating equipment. These API 682 guidelines are considered a standard for best practices.

Take, for instance, API 682 Single Seal Flush Plans. A flush plan is an arrangement that circulates fluid to or from the seal chamber, typically by means of tubing equipment and fluid treatment devices. The goal is to maintain proper lubrication, pressure, temperature, and solids management, and thus prolong the life of the seal.

The fluid can either be from the process itself or from an external source. Typically, the simpler the process is, the simpler the flush plan can be. So when the pumped fluid is clean, does not exceed the temperature limits of the seal, and is compatible with the seal components, you can use a method called a bypass flush. A bypass flush provides circulation flow past the seal faces to carry away seal generated heat. The seal operating temperature will stabilize at the temperature of the pumped fluid.

Normally, this consists of a piping run from the pump discharge to the flush connection on the seal gland, providing flow from the pump, past the seal, and back into the pump through the seal chamber throat. Or it can be piped from the flush connection on the seal gland back to the pump suction, sending the flow in the opposite direction.

Simple plans can use the suction or discharge pressure of the pump to move fluid across the seal faces.

Getting complex

But let's say you want to isolate the seal from the pumped fluid. Then you can use the external flush method. An external flush consists of a minimal flow of a clean, relatively cool liquid (usually water) from an external source injected into the seal gland flush connection at a pressure higher than the pump seal chamber pressure. The external flushing liquid flows past the seal and into the pump, mixing with the pumped fluid.

But let's say you want to isolate the seal from the pumped fluid. Then you can use the external flush method. An external flush consists of a minimal flow of a clean, relatively cool liquid (usually water) from an external source injected into the seal gland flush connection at a pressure higher than the pump seal chamber pressure. The external flushing liquid flows past the seal and into the pump, mixing with the pumped fluid.

A control valve, gauge, and flow meter should be installed in the flushing liquid supply line to provide the control functions needed to set and monitor the flushing liquid supply.

When you have specialized fluids that mustn't leak to the atmosphere or will not permit dilution with seal water, a double mechanical seal will be required. In these cases, the flush plan will act as a miniature loop of barrier or buffer fluid.

Guided by API 682 : Pumps - Shaft Sealing Systems for Centrifugal and Rotary Pumps, we have created standard kits and assemblies that can be tailored to your facility. We can start helping you work on a health plan for all the mechanical seals at your site. Learn more about Swagelok Mechanical Seal Support Systems and/or get in touch with us through our Swagelok Mechanical Seal Support Systems webpage >>

API 682 Design Optimization in Action (Video)

More like this:

- We Shrank This API 682 Seal Panel (blog article)

- Fluid System Design Optimization (Service)

- Swagelok Grab Sample Systems (Solutions for Grab Sampling)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)