Share this

Gaining the Swagelok tube fitting advantage

by Jeff Hopkins on 10/2/12 5:00 AM

Swagelok gaugeable tube fittings and adapter fittings feature a strong grip with no torque, which produces a seal that stands up to hard use. [Updated Jan 2020.]

Tip: Download 34 Swagelok tube fitting performance product test reports, and info specific to several industries.

Tip: Download 34 Swagelok tube fitting performance product test reports, and info specific to several industries.

The two-ferrule mechanical-grip tube fitting

Sometimes you hear a term so often you forget about the meaning behind it. Take the term "tube fitting", for instance. Tube fitting is a general term used to describe categories of components whose purpose is to create a leak-tight connection between a piece of tubing to one or more additional pieces of tubing or other end connections in a fluid system.

The famous Swagelok two ferrule mechanical-grip tube fitting was introduced 65 years ago, and has been the standard ever since.

Wanted: 100% leak-proof fitting connection

System leakage most often occurs at the connections in a system, where fittings under stress can fail. Reliable fittings, then, are crucial. We do acknowledge there is no such thing as a fitting connection that is 100 percent leak-proof under every possible condition. But some designs are inherently better than others. Simple compression fittings, for instance, can't handle much pressure or vibration. Flare fittings can handle higher pressures, but require special flaring tools to prepare the tube.

With these limitations in mind, Swagelok developed the two ferrule mechanical grip fitting in 1947. Swagelok's patented back-ferrule geometry creates a fitting that performs remarkably well in three key areas:

- Tube grip for pressure containment

- Gas seal for leak tight performance

- Vibration resistance for protection from outside forces

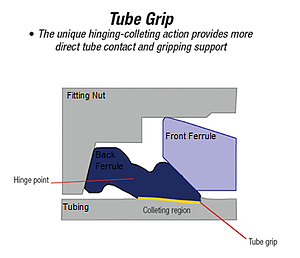

Our illustration depicts a cross-section of the fitting in action. As the fitting nut is tightened, it drives the back ferrule into the front ferrule. Notice the "hinge" in the back ferrule. When the back ferrule is driven forward, it grips the tubing and the hinging action creates a large "colleting" region. The colleting region provides improved support to the tube behind the point of grip which protects the swaged area of the tube more effectively from system vibration and fatigue.

The back ferrule is specially hardened in a way that keeps the steel ductile and provides excellent corrosion resistance. Our illustration below portrays the action of the front ferrule. As it moves forward, it polishes the tube and the fitting body bevel which produces a leak-tight gas seal.

The big three

This video clip focuses on the importance of tube grip, gas seal, and vibration protection in tube fitting performance:

When are leaky fittings an option?

Never. A leaky fitting can be expensive and dangerous. In addition to wasting energy, they can hurt product quality and even cause injury. Fixing a leak means unwanted downtime and labor expense. As with many plant operations, prevention is the safest and most economical approach. So start by having the right fittings for the job, using a design that you can rely on.

Stop leaks

Our engineers can check your compressed gas system and spot the leaks. We find leaks as small as 1 x10-3 cm3/s, tag and catalog them, and present you with a detailed report designed to help you act.

Our engineers can check your compressed gas system and spot the leaks. We find leaks as small as 1 x10-3 cm3/s, tag and catalog them, and present you with a detailed report designed to help you act.

Case studies

Case studies

See how others use Swagelok in dozens of videos and written stories.

More articles like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)