Share this

Is Gland Packing Still Serving Its Purpose for Bay Area Refineries?

by Paul Lesnau on 10/13/20 8:45 AM

How many pumps with gland packings are still in operation in your Northern California Bay Area refinery? Likely, more than you estimate. Your encounters with them may be the frequent tightenings to stave off leakage or replacing gland packings when another turn of the wrench fails to stop the leak. Even though you don’t think about them much, you should spend some time considering whether those gland packings, installed way back when, are serving their intended purpose.

After working many years with local petrochem refineries, I’ve seen the best and the worst of gland packings. At the end of the day, I believe that, in many instances, they have outlived their purpose. Let me share why I’ve come to that conclusion. I’ll start with why they were chosen in the first place.

Is the Original Purpose of Gland Packing Still Relevant?

When properly maintained, gland packings are appropriate for non-toxic, low-temperature processes. With a cooling jacket, they can still only handle temperatures up to 356°F (180°C). Plant water, boiler feeds, steam, and condensates are prime applications. Originally, they were chosen because gland packings are inexpensive and generally easy to keep up by lower-skilled personnel.

But when it comes to the majority of modern refinery pumping processes, gland packings have often outlived their purpose; there are significant disadvantages. They’re transforming sour crude into gasoline, kerosene, diesel, fuel oil, and dozens of other products. Many refinery pumping processes transport toxic, high-pressure, high-temperature hydrocarbons. Secondary pumping processes involve smaller volumes of corrosives, acids, solvents, or wastewater.

And if that gland packing leak, for instance, is a hazardous fluid, the threat of sanctions from Cal/OSHA or the BAAQMD should be reason enough to reconsider gland packings. Even if pumps don’t pose environmental risks, the time involved in tightening packing glands, replacing packings, and production loss undermine the low-cost argument for gland packings.

Then there’s the issue of maintenance skills. With an aging petroleum industry workforce, fewer technicians understand the “art” of gland packing upkeep. Typical problems associated with incorrect maintenance include:

- Overtightening increases friction, reduces drive efficiency, wears down the pump shaft, and shortens gland packing life

- Insufficient tightening causes leaks that foul bearings, leading to inevitable bearing failure

- Incorrect replacements, using the wrong size/design (pre-cut rings, custom-cut, pre-compressed, braid) or wrong material (impregnated PTFE, synthetic fiber, graphite, cotton)

|

A Checklist to Decide Whether Gland Packings Have Outlived Their Purpose |

|

One or more of these factors indicate the need to switch to mechanical seals and seal support systems.

|

With these complications, it’s time to reconsider the use of gland packings.

When Gland Packings No Longer Serve Their Purpose

As you review your inventory of refinery pumps and discover pumps with gland packings that are no longer serving their purpose, take my advice: spare yourself the trouble of trying to figure out the best replacements. Work with local experts who can help you navigate the maze of options available to you.

Begin with your mechanical seal vendor who’ll recommend the right seals—there’s a wide range, purpose-built for every pumping condition. Then take those recommendations to a local mechanical seal support system vendor. They’ll match the seal support system to the specific mechanical seal and pumping process.

It’s not just simply picking the right seal support system or components from a catalog. Many pumps, installed years ago in Bay Area refineries, are encumbered by infrastructure that has grown up around them. They’re difficult to access and maintain—all the more reason that planned gland packing maintenance may have been overlooked.

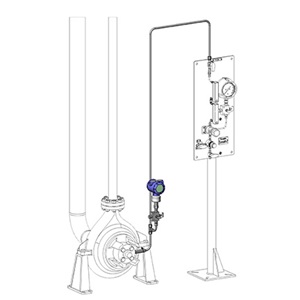

Seal Support Systems Designed and Configured—Purposefully

The best seal support system vendors conduct an on-site evaluation to assess any implementation and maintenance challenges. Every seal support system will be carefully designed and configured to the needs of the mechanical seal and pumping process and the surrounding infrastructure. Custom configurations may include:

- Panel layout and piping geometry that facilitate a quick assessment of system performance and ease of maintenance

- Components and instrumentation such as heat exchangers, filters, gauges, and bypass loops provide the seal chamber environment to ensure optimum mechanical seal operation

- Design elements to accommodate high-vibration environments or exposure to inadvertent damage by maintenance personnel

|

|

These value-added services should include engineering drawings with detailed technical specifications for each system. Attention to detail in the design process ensures smoother implementation and more reliable operations for years to come.

Get Swagelok Service for a Smoother Transition to Mechanical Seals

Swagelok has helped Northern California refineries to successfully make the transition from gland packings to mechanical seals and seal support systems. We offer the full range of API Plans to support Northern California refinery needs. Our Field Engineers welcome the opportunity to get their hands dirty on-site to fully assess the pump environments and design appropriate solutions.

Experienced Swagelok technicians then fabricate and thoroughly test each seal support system in our facilities in Fremont and Concord prior to delivery. The seal support systems we deliver come with the industry's strongest Lifetime Warranty. When gland packings no longer serve their purpose, we are ready to help you make the change.

To find out more about how Swagelok Northern California can help you make the transition from gland packings to mechanical seals and support systems by providing expert consultation and Assembly Services, contact our team today by calling 510-933-6200.

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

About Paul Lesnau | Sales Manager, Business Development Manager, and Field Engineer

Paul holds a B.S. in Mechanical Engineering from North Dakota State University. Before joining Swagelok Northern California, he was the West Coast Regional Sales Manager for an organization focused within the pneumatic and hydraulic industry where he supervised product distribution throughout the western United States, Canada, and Mexico. While in this role, he was able to help provide technical and application-specific expertise to customers and distribution to drive specifications.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)