Share this

Swagelok Hose Comes with Swagelok Quality and Fast Local Assembly

by Jeff Hopkins on 1/15/20 8:45 AM

We can build hose to your order right in Fremont, sometimes faster than you think

"The wrong hose—or even the right hose improperly installed or used—can slow down production, and you may not even be aware of how much time and money it’s costing."

- From Our Hose Experts Can Help You Get The Most From Your Hose

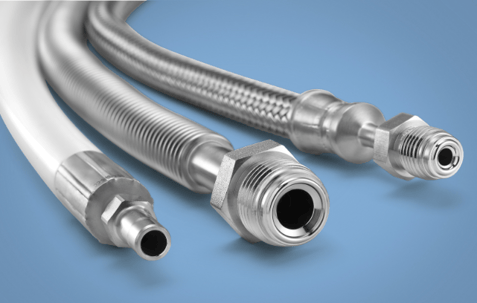

What's the difference between hose and flexible tubing? To be a hose, it must have some reinforcement around the core. That helps increase resistance to pressure, kinking and crushing.

Cores and covers

The core of a hose might be made of metal, PTFE, PFA, vinyl, nylon, polyethylene, or rubber. Each type of core is good for some things and less good for others. Metal cores, for example, work well under a wide range of temperatures, but can suffer from flex fatigue if they need to move around. PTFE cores, on the other hand, are flexible, but they aren't as compatible with small-molecule gasses such as helium and hydrogen as all metal hose due to permeation.

In a tightly regulated industry like biopharmaceuticals, plant operators can’t change parts on a whim. Fortunately, Swagelok U series PFA hose has all the necessary FDA compliance, and documentation comes with each hose certifying the materials of construction, and the pressure testing. The non-aging and chemical compatibility characteristics of the PFA are combined with ultra-flexibility and outstanding kink resistance to provide superior reliability.

Cores can be either smooth or convoluted like the bendy part of a flexible drinking straw.

Some hoses also have a cover. Covers are good to have in conditions where the hose is likely to get scuffed, or if you are concerned about someone getting burned because the fluid inside the hose is really hot. But covers by themselves don't increase flexibility or increase the ability to handle pressure.

Bend, not Oregon

The tightest radius you can bend a hose is called, naturally, the bend radius. But it's also important to consider the force needed to make such a tight bend. A hose bent under too much force shortens its life and puts extra stress on the equipment it is attached to.

The tightest radius you can bend a hose is called, naturally, the bend radius. But it's also important to consider the force needed to make such a tight bend. A hose bent under too much force shortens its life and puts extra stress on the equipment it is attached to.

Hoses that are over-bent will kink. That cuts down flow and can damage the hose itself. If the hose has a natural curvature and you try to bend it in the opposite direction, you can cause similar damage. We offer the correct fittings for those times when you need to attach a hose in a way that goes against its natural curvature.

When we measure a hose, it's typically end-to-end, including the fittings. That means the flexible part is a little shorter than the full length. We call that shorter portion the "live length."

Labeling and Packaging

In addition to the hose itself, we offer a variety of labeling options. Choose from self-adhesive labels, matte tags that are color coded, or Perma Tags with up to five lines of information and protected by a silicone gel and sleeve. In the future we plan to offer RFID tagging as well.

Fast Action

A leaking hose can shut down an entire operation. A customer with that kind of emergency needs a replacement now. A lot depends on the individual specifications and stock on hand, but in an emergency we can have a 20-foot hose ready at our Fremont will call counter within about two hours.

A leaking hose can shut down an entire operation. A customer with that kind of emergency needs a replacement now. A lot depends on the individual specifications and stock on hand, but in an emergency we can have a 20-foot hose ready at our Fremont will call counter within about two hours.

Different hoses have different materials of construction that affect maximum length, but we have built some hoses up to 1,800 inches long. If a customer is willing to accept splices, there's virtually no length limit at all.

We help our customers quickly, and our products work. There really isn't much we can't do when it comes to hose.

Just ask

Swagelok Northern California has a great deal of exposure to all aspects of fluid system design and engineering. Whether you have a simple question or a complex challenge, we're glad to hear from you.

More like this:

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)