Share this

SEMI President Karen Savala Previews SEMICON West 2014

by Jeff Hopkins on 6/18/14 8:00 AM

Annual trade show adds Semiconductor Technology Symposium to events list

We're looking forward to making another appearance this July at SEMICON West 2014, the flagship annual event for the global microelectronics industry. We recently checked in with Karen Savala, president of SEMI Americas, about what to expect at the 44th year of the conference and exhibition, and what issues the industry is facing.

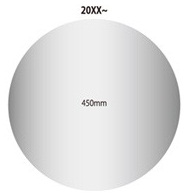

New this year at SEMICON West is the Semiconductor Technology Symposium, which is a new comprehensive technology and business conference addressing the key issues driving the future of semiconductor manufacturing and markets. Aligned with the latest inputs from the International Technology Roadmap for Semiconductors (ITRS), sessions at the STS will focus on the critical trends shaping near-term semiconductor technology and market developments in areas including 450mm, advanced processes and materials, lithography, metrology, yield, design packaging, and test. For 2014, the Test Vision 2020 workshop will join the STS session agenda to address the key trends in ATE. STS is a paid conference with premium content, reserved seating and networking lunches. SEMICON West still has over 50 hours of technical and business programs and events and 20+ hours of free TechXPOT sessions. More than 600 exhibitors will be at the show.

"As far as topics, it's all about R&D," Savala says. "Front-end wafer processing, advanced materials, packaging, testing, and a new focus on components and subsystems." The hot topics include: vertical transistors, FinFETs; graphene; next-gen memory architecture; advanced materials; More than Moore technologies; manufacturing challenges for mobile/IoT; 450mm; EUV; and 3D-IC. This year, SEMICON West features three special displays— nascar, 3D Printing and a Fuel Cell car.

Savala added that “Process innovations for semiconductors are expanding across adjacent and emerging microelectronics technologies and new and emerging markets require collaboration across the supply chain. SEMICON West serves as a platform for collaboration and exploration of new business and technology opportunities.

Supporting startups

The barrier to entry for startup companies is high these days, partly because many private venture capital firms have lost interest in semiconductors, she says. That's why SEMI introduced the Silicon Innovation Forum last year, and will repeat it this year.

"Silicon Innovation Forum connects early-stage technology companies and prospective investors from industry and the investment and venture capital community. The Forum gives exposure to innovative start-ups and entrepreneurial companies while also providing exhibitors, attendees, and investors the opportunity to identify new prospective partners and business opportunities. The program this year will provide a unique platform for 25 or 30 startup- to mid-stage companies. SIF is sponsored by the corporate venture arms of Applied Ventures, Intel Capital, Micron Ventures, Dow Chemical, Tokyo Electron, Samsung Venture Investments and BASF," Savala says. "These companies have their own corporate venture arms to go out and look for new technology."

Executive sessions

The keynote addresses this year at SEMICON West include Mark Adams, COO of Micron, . "What's interesting about them is that they have been on an acquisition spree. So they are now a major player in memory manufacturing," Savala says. "I'm sure they will be talking about their new view of the world from this vantage point.”

The SEMI behind SEMICON West

SEMICON West has always been a popular event, but not everyone who attends has a deep understanding of the organization behind the event.

SEMI supports its members by helping them get together to discuss new developments and solve challenges. Savala says, “While SEMI is focused on semiconductors, it's much more than that. We are also the association for Printed Electronics, MEMS, photovoltaics, flat panel displays and other related technologies.

Savala has a rare perspective on the semiconductor industry, having watched it grow and change as she rose through the ranks during her 30 years with SEMI. When she started, fresh out of college, a considerable amount of chip manufacturing was done right here in California. Then offshoring became the trend. Today, it looks like local manufacturing is making a comeback.

"I believe that companies have found that the allure of offshoring hasn't really paid the dividends that they hoped it would," Savala says. "We see wages in China growing. Over time, that labor cost advantage that you thought you were getting is not there."

450mm transition

SEMI standards such as safety standards, purity standards of chemicals, equipment uptime and other benchmarks provide important consensus and documentation for coordinating efficient advancement of technology. Similarly, SEMI plays a crucial role in the coordination necessary to proceed with the early stages of planning for the transition to the manufacturing on 450mm wafers.

This transformation is not just about 450mm wafers and 450mm wafer tools, but about the facilities and supply chains that support it. "SEMI, as a neutral party, brings the relevant and interested players together to talk about common issues in a pre-competitive way," Savala says.

Swagelok is part of the Facilities 450mm Consortium, known as F450C. Along with other industry consortia, F450C is working hard to hold down operational costs, improve tool and equipment uptime, and otherwise provide long-term benefits as the industry builds high-volume 450mm facilities. Swagelok's role within the F450C will focus on tool installation efficiencies, cleaning specifications, training requirements, safe working environment standards, and other facility requirements.

While the urgency of volume-manufacturing implementation has abated pending synchronization among the IC makers that may eventually build a 450mm fab, continued supply chain coordination and planning remains relevant. Savala says, “Of course, SEMICON West will keep attendees up to date. We will be featuring a day-long program on Thursday, starting with our traditional 450mm panel discussion. There also will be a panel discussion about how wafer transition timing will affect current manufacturers.”

One of the questions is whether some of the development work done for 450 can be retrofitted or applied to 300mm to optimize technology for another three to five years. "A long tail of supply chain participants, who may not be as close to the tool development programs, will benefit from better understanding of the overall transition planning," Savala says. "Collaboration is an overused word. Everyone throws it around like it is easy to do. We would like to see that these conversations provide material guidance to help companies’ better plan and allocate resources through a dynamic and uncertain transition.”

When you come to SEMICON West to keep up with the news of the industry, we hope you'll stop by the SEMI booth (#1329) in the South Hall. We'll be there through the entire event, July 8-10 at Moscone Center in San Francisco. Get free registration to SEMICON West 2014 courtesy of Swagelok Company here »

Additional Resources

|

||

| Free Registration to SEMICON West 2014 | 2013 450mm Transition Forum |

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)