Share this

Case Study: Swagelok Dielectric Hose In Semiconductor Manufacturing

by Jeff Hopkins on 6/27/13 7:00 AM

Swagelok W Series PTFE hose solves the problems of temperature control and excess bulk

One crucial part of making semiconductors is the ability to accurately control the temperature of the semiconductor tools. To do that, fluids are delivered via hoses to either heat or cool the space around the tool chamber. A stable chamber means a stable chip yield, so hoses are a critical piece of the puzzle. Temperature swings are a prominent challenge in semiconductor manufacturing.

For a long time, the primary heating and cooling media were ethylene glycol and deionized water. For a water-glycol mix, a plain rubber hose could deliver good results. It’s basically the same system that has been used to cool car engines since Henry Ford was making the Model T. However, Chip design is always improving, and new processes are demanding higher temperatures. As a result, chipmakers prefer to use dielectric media. That brings a whole new set of challenges.

Critical tasks

A hose has to satisfy a chip manufacturer on many levels at once: safety, performance, cleanliness and temperature capability range at a minimum. Legacy hoses no longer hold up to changing conditions. First, dielectric materials are caustic to standard rubber. The core starts to break down after a while. The dielectrics themselves are extremely expensive, $500 or $600 a gallon. They absorb into the atmosphere fast. A handful can evaporate in 30 seconds, so a leak can be very expensive.

With the new conditions becoming prevalent in the industry, temperature range has become a critical factor. If the exterior of the hose gets too hot, it becomes a safety issue. If the hose surface gets too cold and water starts condensing on it, water could drip on to some other important piece of equipment and damage it, or onto the floor and cause another safety hazard. As the humidity in the surrounding air rises, condensation will appear more quickly. A hose that doesn't insulate well also drains away profits, because the company has to use bigger chillers and heat exchangers to make up for the temperature fluctuations in the hose.

On top of that, dielectric media is hydrophilic, which means it seeks out moisture. Even in a cleanroom, human beings add moisture to the air simply by breathing. So the hose must not let moisture in.

Immediate need

One of our customers was establishing a new platform for transferring dielectric media using fluids sold under the trade names Galden and Fluorinert. It was a big change for the company because they were upgrading to chambers twice the size they had been using.

The new platform had to meet industry and OSHA requirements, and keep the fluids within a couple of degrees of specification for production. The new system also had to incorporate legacy dripless quick-connects. If any fluid were to escape, it would hit the floor and trip special sensors. That would lead to more labor expense, down time, and lost yield.

Swagelok W Series PTFE hose fits the bill

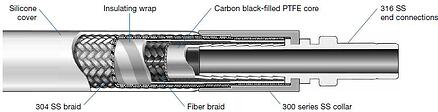

We had the answer: Swagelok W Series PTFE hose. This series evolved out of conversations that Swagelok had been having with customers, who said they needed a non-contaminating hose core that could also handle the temperature, insulation, and media that the process demands. In addition to meeting the insulation criteria, Swagelok W Series PTFE hose uses a carbon impregnated PTFE core that conveys any potential electro-static charges to ground thus preventing potential arcing. There's no chance of electrical arcing or burning pinholes through the hose as the dielectric material moves through. In the past before dielectric media was used, this had not been a concern.

Swagelok W Series PTFE hose is a five layer hose with lots of mechanical strength. That means it will not kink when it is properly suspended from the floor to the chiller. For this application a sixth layer (called Fire Jacket) was added for additional insulation. It acts as a barrier to moisture, heat and particulates, and it is delivered on the hose, rather than having to be installed on site by the customer or a contractor. A Fire Jacket cover is available as an option on many Swagelok hoses.

As semiconductor technology drives toward tighter and tighter chip geometry, defects from particulates and other contaminants become a bigger and bigger problem. The W Series PTFE hose meets clean room Class 100 specifications. It also does not off-gas any volatile organic compounds.

Full bore

3/4 inch i.d.(inside diameter) W series PTFE hose also offers superior flow rates versus the legacy 3/4” hose. Typical 3/4” hose has an inside diameter of 5/8 inch. W series PTFE hose is a 'full' 3/4" i.d. It also offers significant routing advantages. Its o.d. (outside diameter) is significantly smaller than typical hoses: The o.d. of 3/4” W series PTFE hose is 1.375 inch while conventional hose can be 3+ inches. That becomes very important on a four-chamber tool, with separate supply and return hoses connected to each tool. That's eight hoses feeding through a bulkhead. Thick foam insulation makes the hoses unwieldy, and certain types of foam are prone to flaking. That’s simply not acceptable anywhere near a clean room.

Product test reports

To show what W series hose could do, we set up a special product test. We hooked up several W series hoses to a heat exchanger, and then put thermocouples on the skin of the hoses. We charted the temperature and overlaid that line with the temperature of the fluid inside the hoses. The two lines showed how the hoses were able to insulate well, prevent heat loss, and help maintain a stable temperature range. We also were able to incorporate the legacy quick-disconnect fittings, so the new designs will work on legacy systems. Product test reports »

In house testing and assembly

We were able to deliver the hoses when the customer needed them and configured to their specifications (length, additional insulation, testing, and the legacy quick-disconnect fittings) because we have a team of full-time assembly technicians building hose in our dedicated hose cell. They are supported by a team of buyers, estimators, and production planners handling the front end of the operation. Together, they help customers by supplying thousands of custom hose assemblies each year.

Within our assembly process we maintain tight tolerances and certified testing. The hose cell is equipped to conduct hydrostatic tests, helium leak tests, and pressure decay testing. We can provide documentation with any hose on request. The assembly technicians are certified by Swagelok manufacturing engineers. Learn more about our in house hose assembly and testing here.

Color coding for added safety

In this particular application, 75 foot hoses are plugged in at the heat exchanger in the sub-fab and then run up through the floor. Someone who is new to the job or who gets distracted could very easily misconnect some of the hoses. We dealt with this problem by providing color-coded hoses. Combined with a chart kept on site, a person can easily make the proper connections without even knowing what each hose does.

Many applications

Because of the many capabilities of Swagelok W Series PTFE Hose:

- Safety through color coding

- Custom local assembly and testing

- Insulation and temperature control

- Static dissipation

- More flow through full bore i.d.

- Ease of installation from its uniquely flexible core technology

- Better routing from its slimmer o.d.

it also gives our customer economies of scale. They can also use it for plasma etch, deposition, and thin film applications like high-temperature fusion, rapid thermal, and implant processes. Swagelok W Series PTFE hose can be used in 90 percent of their tool applications.

More information about Swagelok W Series PTFE hose is available here..

Additional resources

Downloads

|

|

| Swagelok Hose and Flexible Tubing Catalog (88 Pages) | Swagelok Hose Selection Tutorials (35 Slides and 9 Pages) |

Related articles

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)