Share this

Pressure Regulators Control Outlet Pressure Not Fluid Flow

by Jeff Hopkins on 6/23/17 9:00 AM

How pressure reducing regulators maintain outlet pressure as inlet pressure and flow varies

A pressure regulator is a fluid system component designed to control outlet pressure under a given set of inlet pressure and flow conditions.

Two types of pressure regulators

There are two broad categories of pressure regulators: pressure reducing regulators and back pressure regulators. Two of our webinars focused on the more common of the two types: the pressure reducing regulator. A pressure reducing regulator maintains outlet pressure as inlet pressure and flow varies.

The primary reasons for regulating pressure is to provide accurate, consistent, and repeatable delivery pressures to processes and process equipment in order to reduce the likelihood of process variability and to protect sensitive equipment.

In order for processes and pressure sensitive equipment to work properly, high pressure process fluid must be reduced to an acceptable pressure before entering the point of use, this pressure reduction may be achieved through the use of one pressure regulator or through a series of pressure regulators. If pressure is not reduced and controlled, the process may shut down or sensitive equipment may be damaged.

Three main components

A typical regulator has an inlet where fluid enters the regulator, an outlet where fluid exits the regulator, and an orifice through which the flow of the fluid is directed.

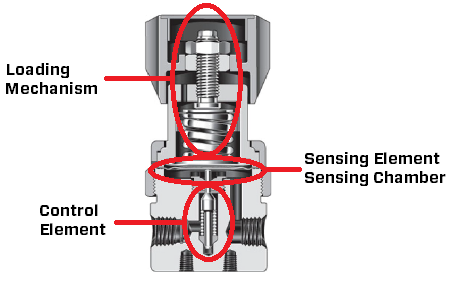

Regulator components are manufactured using a variety of designs. Although, there are many design options on the market, most pressure regulators contain three main components that perform similar functions regardless of design: the control element, the sensing element and sensing chamber, and the loading mechanism.

Control

The first component to mention is the control element, often referred to as the main valve, valve stem, or poppet, it is used to control the outlet pressure of the fluid by moving into and out of the orifice.

When the poppet moves into the orifice, fluid flow is restricted and outlet pressure decreases, conversely, when the poppet moves out of the orifice, fluid flow and outlet pressure builds.

Most pressure regulators contain three main components that perform similar functions regardless of design

Sensing

The second component is composed of two parts, the sensing element and the sensing chamber.

The sensing chamber is the area just below the sensing element. The sensing element responds to pressure changes in the sensing chamber.

The stem of the control element is in constant contact with the sensing element. The sensing element and control elements move together as pressure changes in the sensing chamber.

Loading

The third component is the loading mechanism. The loading mechanism exerts force on the sensing element to counterbalance the pressure of the fluid inside the chamber.

The loading mechanism is set or adjusted to provide the desired outlet pressure of the regulator.

Summary

There are three key elements that allow a pressure reducing regulator to function.

- The control element governs flow by moving into and out of the orifice.

- The sensing element detects changes in outlet pressure.

- The loading mechanism exerts force on the sensing element to counterbalance the pressure of the fluid inside the chamber.

It is important to remember that pressure regulators control only pressure, not fluid flow. Pressure regulators react to changes in fluid flow, but control only pressure.

additional resources

get in touch

In a hurry or have a question? Please click here to get in touch - we respond fast! Or call 510-933-6200.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)