Share this

Hose With the Strength of Steel Handles 6,000 psig (Video, Cutaway)

by Jeff Hopkins on 3/29/18 8:45 AM

Why our customers use FX Series hose in high pressure corrosive environments, high-temp vacuum environments, and more

“Our expert operators and strict process control in manufacturing result in unmatched quality and consistency customers can count on. Our products are also backed by the Swagelok Limited Lifetime Warranty, proving our dedication and commitment to quality and our customers.”

- Doug Nordstrom, Swagelok Product Manager, Hose Products

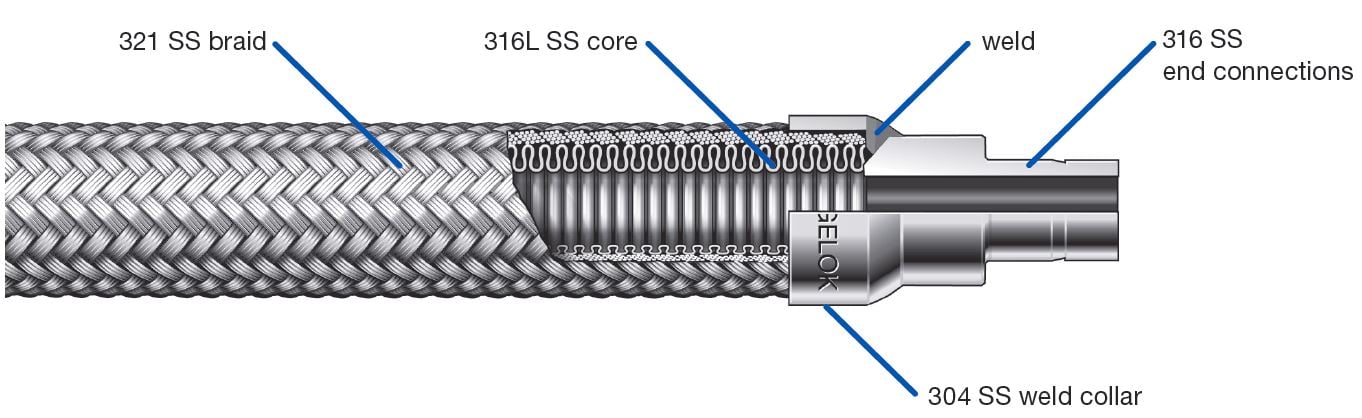

You want the performance of stainless steel tubing, but you also want some of the flexibility of hose. Swagelok has the solution: FX Series metal hose. Check out the cutaway and video below, then get our new Hose Pocket Guide:

This double-braided hose series offers 1/4-inch to 2 inch nominal hose sizes with a temperature range of –325 to 1000°F (–200 to 537°C) and working pressure ranges from vacuum to 6000 psig through vacuum to 1122 psig.

It's all corrosion-resistant metal, from the 316L stainless steel annular convoluted core to the 321 stainless steel double braid layers to the 316 stainless steel end connections, which are welded to the 304 stainless steel collar. It can handle high pressure corrosive environments, high-temperature vacuum environments, and is an excellent choice anywhere permeation is undesirable.

Swagelok FX hose is specifically designed for high pressure applications in chemical, compressed gas, cryogenic, hydrogen and fuel cell, marin, oil and gas, power, and pulp & paper.

High-pressure corrosion resistant all-metal hose with double braid layers of 321 stainless steel that promote hose pressure containment.

Range of end connection options

You have your choice of end connections: Swagelok Tube Adaptors, Swagelok Tube Fittings, female VCO O-ring Face seals, SAE 37-degree (JIC) female swivels, female pipe threads, male pipe threads and tube butt welds.

As with many other Swagelok hoses, you can get optional hose covers, hose tags and helium leak testing.

Getting FX Series hose your way

There's a second kind of flexibility that comes with our hose. That's the flexibility of our technicians who can fabricate hose to your specifications right here at Swagelok Northern California.

Tell us the length you need, the end connections and options you need and how many pieces, and we'll build them for you in our 1,200-square-foot hose shop (all metal hose is manufactured to order in our Swagelok facility in Ohio).

We can test 100 percent of the hoses we make. We can do a hydrostatic test, an immersion test, and pressure decay testing. And we can provide documentation with any hose if requested. If the need ever arises, we can trace each individual hose back to the original assembler. Each assembler, by the way, has to be certified by Swagelok manufacturing engineers to make sure they know how to use the equipment properly and safely.

What's next: Get our new Hose Pocket Guide. Then visit our Hose Assembly page:

(Prefer to talk live? Please give us a call at 510-933-6200.)

- When Will It Burst? (series of videos)

- Going to Extremes In Our Hose Cell (blog article)

- How this OEM stopped backward hose installation (case study)

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)