Share this

Improve Your Engineering Field Services Benchmarking KPIs This Year

by Malik Durojaiye on 3/23/21 9:00 AM

Many process industries in Northern California rely on engineering field services to keep critical systems operational. Engineering field service staff often provide special expertise that exceeds in-house experience or skills. This approach can also be appealing to industries contending with aging workforces. When employees with decades of experience leave, so do a significant amount of practical knowledge. Engineering field services can be vital when short-term specialized engineering skills are needed for a project.

For many organizations, these relationships make economic sense. To ensure that you’re receiving quality support, it’s worth leveraging engineering field services benchmarking KPIs to monitor your field service provider’s performance.

Engineering Field Services Benchmarking KPIs Worth Monitoring

As part of the SLA you have with a provider, engineering field services benchmarking KPIs may be specified in your contract. The types of KPIs you monitor will vary, but I’ve found that three are particularly useful, if not foundational, in assessing the overall quality of services you are receiving.

- mean-time-between-failure (MTBF) for the systems supported by an engineering field services team

- response time to a service request

- mean-time-to-repair (MTTR) for the equipment under service

How well your provider actually meets these KPIs depends on several factors. I’ll explain below how certain capabilities can help improve these KPIs and, in turn, boost reliability for systems such as grab sampling and mechanical seal support.

Positive Impact on Mean-Time-Between-Failures KPIs

I’ve put this benchmark at the top of my list. Why? Because I believe that engineering field services should have a positive impact on this KPI from day one. When you work with an engineering field services team regarding a problematic system, their experience and expertise should result in an improved mean-time-to-failure for the system.

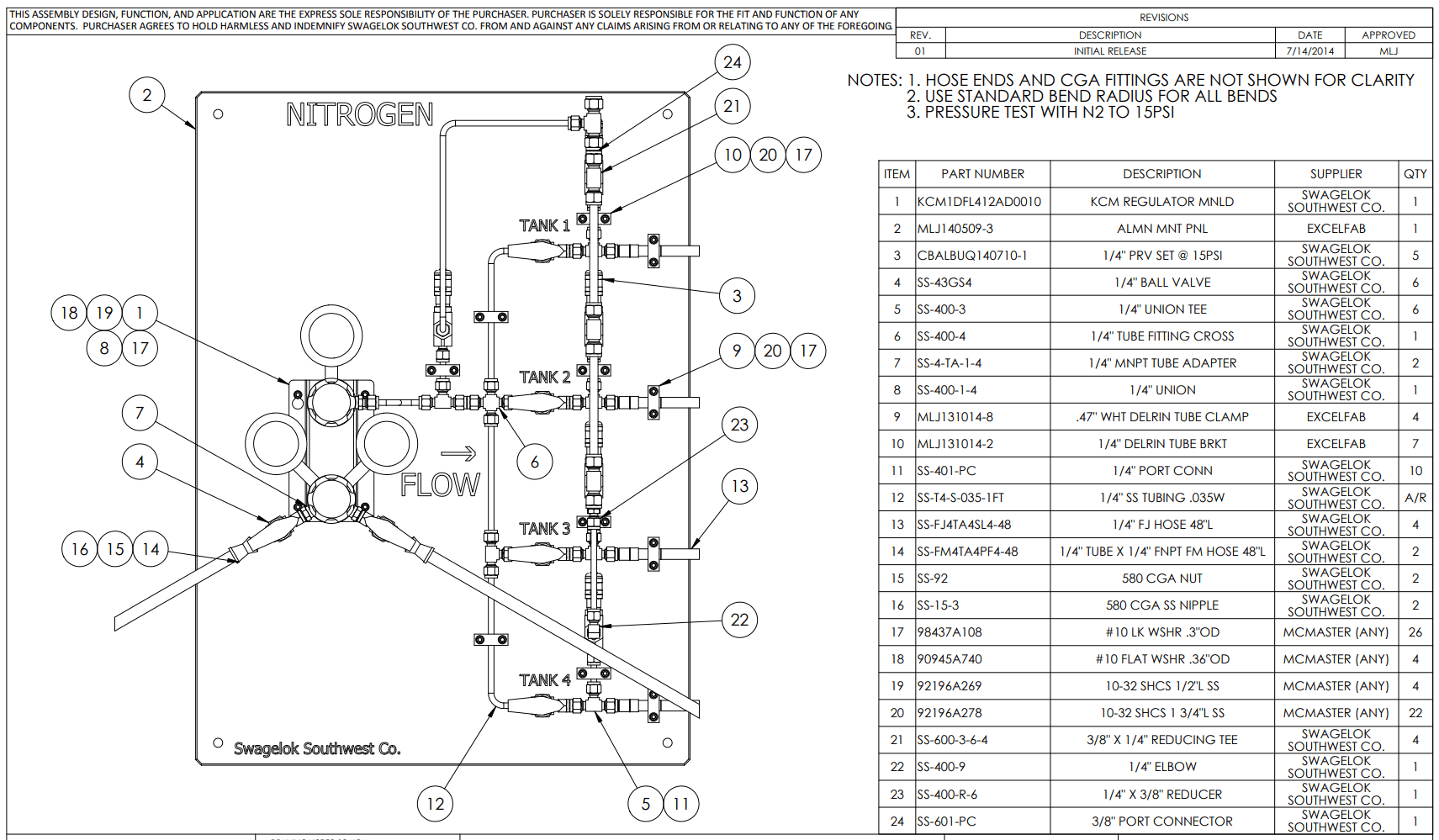

For example, a grab sampling system fails to consistently provide representative samples. An on-site in-depth analysis of the components and subsystem, from tap to analyzer, should uncover the root cause of the problem. The solution may be as simple as a lag time recalculation to avoid a contaminated sample. It could be far more complex and require the replacement of a standard flow panel with a continuous flow panel.

For a pump whose MTBF has become problematic in comparison to the average, an experienced field engineer will look closely at the pumping conditions, type of mechanical seal, and the seal support system to diagnose the problem. Here, problems can span from simple to complex: a malfunctioning pressure gauge fails to accurately report pressure leading to inadequate seal face lubrication, or a custom engineered API Plan 55 with one or more of the components delivering buffer fluid to the seal chamber are malfunctioning.

A knowledgeable and experienced field services engineer should take a holistic approach in accurately assessing the issues associated with problematic fluid systems and make recommendations that immediately improve performance, reliability, and MTBF KPIs.

Mean-Time-to-Repair: System Design Plays A Vital Role

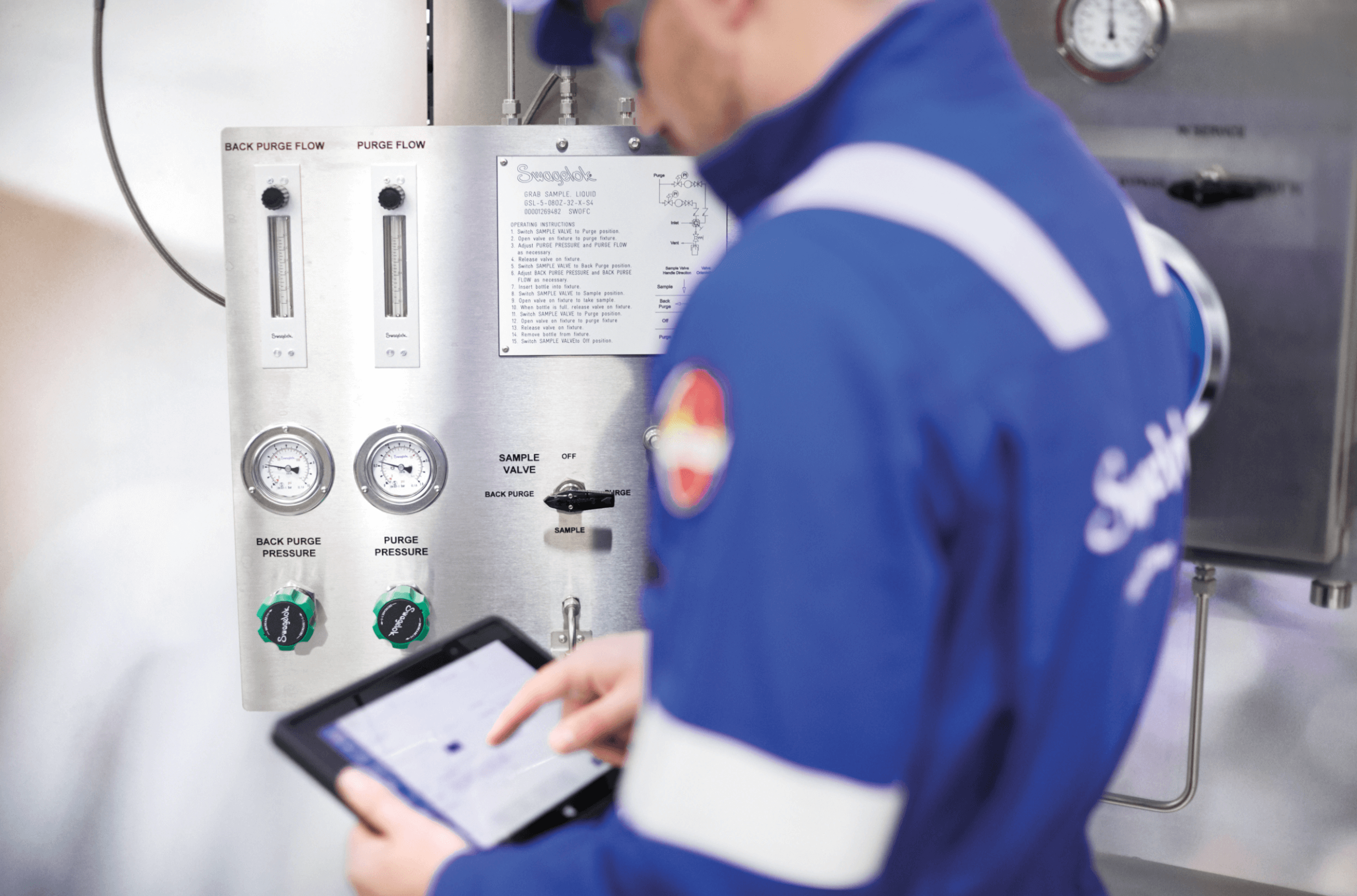

Multiple factors affect mean-time-to-repair. It begins with system design best practices that help minimize downtime. But when the need for repair occurs, a well-designed system is also easier to repair. Good design means controls and components are easily accessible for diagnosis and replacement. In the best cases, system design allows repairs without the need to bring a process to a halt. For example, grab sampling systems with the right valve configuration or bypass flows permit rapid changeout of malfunctioning components.

An extensive local inventory of high-quality fluid assemblies and components also helps improve mean-time-to-repair KPIs. Local inventory eliminates the time and expense of shipping a critical part. Local resources can facilitate same-day repairs in many instances.

If repairs are more complex than a simple part replacement, local repair facilities that also provide testing of the final assembly accelerate repairs and help ensure a first-time-fix that gets your operations back into production.

Response Time: The Advantage of Local Assistance

When you encounter a problem with a system, how quickly can the engineering field services team respond? Although more services are being provided remotely, there’s added benefit when your engineering field services team is local. There’s no substitute for the ability to quickly arrive onsite to diagnose a problem first-hand. A local engineering field services team familiar with the unique aspects of your operations offers faster response time KPIs compared to distant providers and a better level of service.

Swagelok Focuses on Engineering Field Services Benchmarking KPIs

Swagelok has been providing engineering field services to process industries such as chemical, petroleum, semiconductor, and utilities in Northern California for more than five decades. Our team brings local industry experience, backed by global expertise in the design, assembly, testing, and repair of fluid systems. Our facilities in Fremont and Concord carry thousands of standard parts in addition to made-to-order, engineered-to-order, and build-to-order assemblies.

Swagelok’s locally-based field engineers provide on-site or virtual support to help you obtain the maximum reliability and value from grab sampling, mechanical seal support, and a wide range of other fluid systems. We’re constantly focused on the responsiveness and quality of our engineering field services to help customers meet or exceed their own or industry-standard KPIs for reliability.

To learn how Swagelok Northern California's local field engineering team and resources are helping process industries improve key reliability KPIs by providing expert consultation, contact our team today by calling 510-933-6200.

-1.jpg?width=192&name=image8%20(1)-1.jpg) About Malik Durojaiye | Field Engineer, Assembly Services

About Malik Durojaiye | Field Engineer, Assembly Services

Malik Durojaiye began his Swagelok career in 2019 as a Custom Solutions Engineer in our Assembly Services group. Prior to Swagelok, Malik developed as a design engineer as well as a manufacturing engineer for 6 years serving Kentucky and California with Altec Industries; a leading provider of products and services to the electric utility, telecommunications, tree care, lights and signs, and contractor markets.

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)