Share this

The Role of Inert Gas Systems in Semiconductor Fabrication

by Morgan Zealear on 2/2/23 9:00 AM

The unique properties of inert gases have enabled the semiconductor industry to maintain cleanliness and productivity in their manufacturing process. The demand for these gases is so huge that the market is estimated to be worth about 6.1billion dollars by 2028, despite the semiconductor shortage during the COVID-19 pandemic.

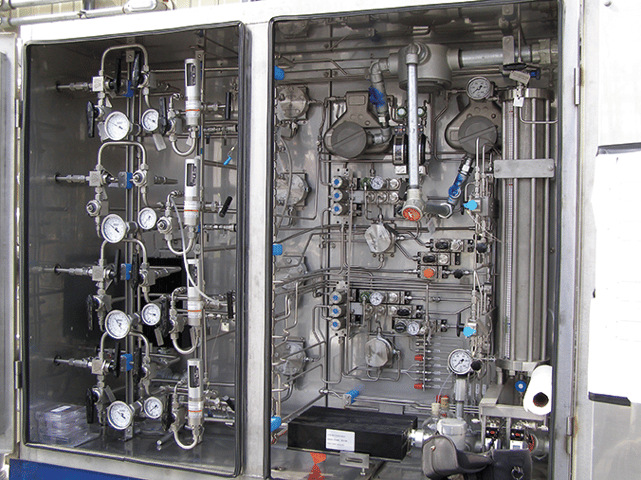

The gas delivery system acts as the mediator between the gas source and the production process. This is where manufacturers should be mindful of preventing leaks and contamination. Custom inert gas systems specific to your process condition will ensure a precision supply of these gases to your fabrication unit. Let us explore the multiple roles of inert gas systems in ensuring the productivity and reliability of your semiconductor fabrication process.

The Different Semiconductor Grade Gases

To establish the standard of what to use and when, the gases used for manufacturing purposes have been specified into three grades, which are:

- Industrial grade

- Labortory grade

- Ultra-high purity grade

Semiconductor-grade gases are high-purity gases used for purging or aiding in different stages of fabrication. The inert gas, in particular, plays a crucial role in different stages of semiconductor fabrication. These include standard inert monatomic gases like argon or helium, though diatomic gases like nitrogen can also be used for blanketing or to provide an inert condition. The table below indicates the types of gases used and the processes in which they are used.

|

Argon |

Offers an inert environment during the etching and deposition phase. |

|

Hydrogen |

Provides a reduced environment for annealing as well as provides support for plasmatic operations. |

|

Nitrogen |

Purges and ensures inert condition for most process systems, including vacuum or gas abatement systems. |

|

Oxygen |

To facilitate oxidation of various elements. |

|

Helium |

Used with silicon to control its temperature during miniaturization. Also, heavily used for leak testing. |

The chemically inert gases help eliminate existing and potential impurities from the different fabrication steps. This inert nature needs to be preserved throughout the process—from the source to the point of use. So, it is crucial for manufacturers to invest in a high-quality inert gas system.

The Role of An Efficient Inert Gas System

Before designing or selecting the right inert gas system, it is beneficial to explore the few challenges that fabrication facilities face. These are:

- Leaks: Leaks lead to the pressure losses, cause contamination, and increase operational/ maintenance costs.

- Safety: Some gases are precursors for chemical warfare. It's about more than just frostbite and burn hazards—it can be life or death.

- Downtime: Frequent maintenance or changeovers leads to unplanned downtime, compromising productivity.

A reliable inert gas system must be robust, safe, and easy to troubleshoot. At each stage of the semiconductor fabrication process, the specialized inert gas system should operate as per the specifications (i.e., temperature, pressure, and gas discharge rate) to achieve the desired reaction. Here are a few things to keep in mind when custom-designing your inert gas delivery system.

1. Backflow Prevention

Manufacturers should be mindful of preventing backflow when dealing with inert gas. Backflow can have serious implications, not just for the impending procedure down the line but also for the safety of the gas delivery system. For instance, if oxygen backs into the system with nitrogen blanketing, the result can be hazardous. Check valves can be used to control backflow for high-purity applications.

2. Temperature and Pressure Control

The T&P control of inert gases directly correlates to the consistency of fabrication in processing chambers. Control and relief valves and pressure regulators can work in unison to achieve the pressure required at the inlet and outlet. Insulation can be used to prevent cryogenic heat transfer.

3. Controlled Mixing

In many cases, the production process may require a mixture of inert or specialty gases. For instance, a diborane and hydrogen mixture may be required during doping to control decomposition. With the use of gas manifolds, these gases can be mixed at the point of use.

Need Help Installing a Reliable Inert Gas System?

The quality of an efficient inert gas system is its ability to provide controlled flow while ensuring there are no unwanted mixing, backflow, or leaks. This can be accomplished by using high-quality components such as valves, manifolds, and pressure regulators—provided by Swagelok. These components can help you fabricate a gas delivery system that enables an uninterrupted supply of inert gas to the processing unit.

Swagelok also provides consultation services for Northern California facilities seeking system optimization advice or help identifying the right solution for the efficient run of your delivery system. Swagelok is your local fluid system expert and your answer to unlocking efficiency and productivity in your semiconductor fabrication process.

To find out more about how Swagelok Northern California can support your need for the design and installation of an inert gas system,contact our team today by calling 510-933-6200.

About Morgan Zealear | Product Engineer, Assembly Services

About Morgan Zealear | Product Engineer, Assembly Services

Morgan holds a Bachelor of Science in Mechanical Engineering from University of California at Santa Barbara. He is certified in Section IX, Grab Sample Panel Configuration and Mechanical Efficiency Program Specification (API 682), and he is well versed in B31.3 Process Piping Code. Before joining Swagelok Northern, he was a manufacturing engineer at Sierra Instruments, primarily focused on capillary thermal meters for the semiconductor industry (ASML).

Share this

- Archive (465)

- Assembly Services (207)

- About (100)

- Seal Support Systems (96)

- Best Practices (88)

- Training Services (74)

- Fittings (51)

- Semiconductor Applications (49)

- Hoses and Flexible Tubing (47)

- Regulators (44)

- Tubing (42)

- Grab Sampling Systems (32)

- Sampling Systems (32)

- Gas Systems (30)

- Services (30)

- Downloads (29)

- Valves (24)

- Application Support (18)

- Orbital Welding (17)

- Case Studies (13)

- Steam Systems (13)

- Frequently Asked Questions (12)

- Tools (12)

- Measurement Devices (7)

- Subsystems (6)

- Thermal Management (6)

- September 2023 (1)

- August 2023 (2)

- June 2023 (1)

- March 2023 (3)

- February 2023 (3)

- January 2023 (4)

- December 2022 (4)

- November 2022 (4)

- October 2022 (4)

- September 2022 (1)

- August 2022 (3)

- July 2022 (2)

- June 2022 (4)

- May 2022 (1)

- April 2022 (2)

- March 2022 (1)

- February 2022 (2)

- January 2022 (3)

- December 2021 (1)

- November 2021 (6)

- October 2021 (6)

- September 2021 (8)

- August 2021 (4)

- July 2021 (3)

- June 2021 (6)

- May 2021 (6)

- April 2021 (7)

- March 2021 (5)

- February 2021 (4)

- January 2021 (6)

- December 2020 (5)

- November 2020 (6)

- October 2020 (6)

- September 2020 (8)

- August 2020 (7)

- July 2020 (8)

- June 2020 (8)

- May 2020 (6)

- April 2020 (9)

- March 2020 (7)

- February 2020 (10)

- January 2020 (21)

- December 2019 (23)

- November 2019 (21)

- October 2019 (22)

- September 2019 (21)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (23)

- April 2019 (22)

- March 2019 (21)

- February 2019 (20)

- January 2019 (21)

- December 2018 (14)

- November 2018 (19)

- October 2018 (23)

- September 2018 (17)

- August 2018 (29)

- July 2018 (11)

- June 2018 (6)

- May 2018 (5)

- April 2018 (4)

- March 2018 (5)

- February 2018 (3)

- January 2018 (3)

- December 2017 (2)

- November 2017 (4)

- October 2017 (3)

- September 2017 (2)

- August 2017 (6)

- July 2017 (4)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (4)

- February 2017 (3)

- January 2017 (3)

- December 2016 (3)

- November 2016 (3)

- October 2016 (3)

- September 2016 (5)

- August 2016 (5)

- July 2016 (4)

- June 2016 (5)

- May 2016 (3)

- April 2016 (4)

- March 2016 (5)

- February 2016 (11)

- January 2016 (1)

- December 2015 (3)

- November 2015 (4)

- October 2015 (3)

- September 2015 (4)

- August 2015 (4)

- July 2015 (8)

- June 2015 (5)

- May 2015 (3)

- April 2015 (4)

- March 2015 (4)

- February 2015 (3)

- January 2015 (4)

- December 2014 (2)

- November 2014 (3)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (3)

- January 2014 (4)

- December 2013 (5)

- November 2013 (3)

- October 2013 (4)

- September 2013 (3)

- August 2013 (5)

- July 2013 (5)

- June 2013 (5)

- May 2013 (3)

- April 2013 (6)

- March 2013 (4)

- February 2013 (4)

- January 2013 (8)

- December 2012 (4)

- November 2012 (6)

- October 2012 (6)

- September 2012 (4)

- August 2012 (4)

- July 2012 (4)

- June 2012 (4)

.webp?width=210&height=70&name=StickyLogo%20(5).webp)